Moving bed biofilm reactor

Moving bed biofilm reactor (MBBR) is a type of wastewater treatment process that was first invented by Prof. Hallvard Ødegaard at Norwegian University of Science and Technology in the late 1980s.[1] It was commercialized by Kaldnes Miljöteknologi (now called AnoxKaldnes and owned by Veolia Water Technologies). There are over 700 wastewater treatment systems[2] (both municipal and industrial) installed in over 50 countries. Currently, there are various suppliers of MBBR systems.[3]

Process description

Overview

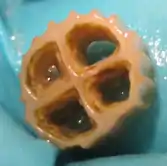

The MBBR system consists of an aeration tank (similar to an activated sludge tank) with special plastic carriers that provide a surface where a biofilm can grow. The carriers are made of a material with a density close to the density of water (1 g/cm3). An example is high-density polyethylene (HDPE) which has a density close to 0.95 g/cm3. The carriers will be mixed in the tank by the aeration system and thus will have good contact between the substrate in the influent wastewater and the biomass on the carriers.[2] To prevent the plastic carriers from escaping the aeration it is necessary to have a sieve on the outlet of the tank. To achieve higher concentration of biomass in the bioreactors, hybrid MBBR systems have also been used where suspended and attached biomass co-exist contributing both to biological processes.[4] There are also anaerobic MBBRs that have been mainly used for industrial wastewater treatment.[5] Recently, a combination of anaerobic (methanogenic) MBBR with aerobic MBBR was applied in the laboratory for municipal wastewater treatment with simultaneous production of biogas.[6]

AdvantagesThe MBBR system is considered a biofilm process. Other conventional biofilm processes for wastewater treatment are called trickling filter, rotating biological contactor (RBC) and biological aerated filter (BAF). Biofilm processes in general require less space than activated sludge systems because the biomass is more concentrated, and the efficiency of the system is less dependent on the final sludge separation. A disadvantage with other biofilm processes is that they experience bioclogging and build-up of headloss. [1]

MBBR systems don't need a recycling of the sludge, which is the case with activated sludge systems.

The MBBR system is often installed as a retrofit of existing activated sludge tanks to increase the capacity of the existing system. The degree of filling of carriers can be adapted to the specific situation and the desired capacity. Thus an existing treatment plant can increase its capacity without increasing the footprint by constructing new tanks.

When constructing the filling degree can be set to, for example, 40% in the beginning, and later be increased to 70% by filling more carriers. Examples of situations can be population increase in a city for a municipal wastewater treatment plant or increased wastewater production from an industrial factory.

Some other advantages compared to activated sludge systems are:[7]

- Higher effective sludge retention time (SRT) which is favorable for nitrification

- Responds to load fluctuations without operator intervention

- Lower sludge production

- Less area required

- Resilient to toxic shock

- Process performance independent of secondary clarifier (due to the fact that there is no sludge return line)

Large diameter submersible mixers are commonly used as a method for mixing in these systems.

Removal of micropollutants (MPs)

Moving bed biofilm reactors (MBBRs) have shown promising results to remove MPs from wastewater.[8][9][10][11] MPs fall into several groups of chemicals such as pharmaceuticals, organophosphorus pesticides (OPs), care products and endocrine disruptors.[12] Recently, there have been investigations using MBBR technology to remove pharmaceuticals such as beta-blockers, analgesics, anti-depressants, and antibiotics from hospital wastewater.[13][9] Moreover, application of MBBR as a biological technique combined with chemical treatment has attracted a great deal of attention for removal of organophosphorous pesticide from wastewater.[14]

The advantage of MBBRs can be associated with its high solid retention time, which allows the proliferation of slow-growing microbial communities with multiple functions in biofilms. The dynamics of such microbial communities greatly depends on organic loading in MBBR systems.[15]

See also

- List of waste-water treatment technologies

References

- Ødegaard, H.; Rusten, B.; Westrum, T. (October 1994). "A new moving bed biofilm reactor - applications and results". Water Science and Technology. 29 (10–11): 157–165. doi:10.2166/wst.1994.0757.

- Ødegaard, Hallvard (2012). Vann- og Avløpsteknikk. Norsk Vann. ISBN 9788241403361.

- Haandel, Adrianus C. van; Lubbe, J. G. M. van der (2012-01-01). Handbook of Biological Wastewater Treatment: Design and Optimisation of Activated Sludge Systems. IWA Publishing. ISBN 9781780400006.

- Mazioti, Aikaterini A.; Stasinakis, Athanasios S.; Psoma, Aikaterini K.; Thomaidis, Nikolaos S.; Andersen, Henrik R. (February 2017). "Hybrid Moving Bed Biofilm Reactor for the biodegradation of benzotriazoles and hydroxy-benzothiazole in wastewater" (PDF). Journal of Hazardous Materials. 323 (Pt A): 299–310. doi:10.1016/j.jhazmat.2016.06.035. PMID 27396311.

- di Biase, A.; Devlin, T.R.; Kowalski, M.S.; Oleszkiewicz, J.A. (June 2018). "Performance and design considerations for an anaerobic moving bed biofilm reactor treating brewery wastewater: Impact of surface area loading rate and temperature". Journal of Environmental Management. 216: 392–398. doi:10.1016/j.jenvman.2017.05.093. PMID 28595913.

- Kora, Elianta; Theodorelou, Danai; Gatidou, Georgia; Fountoulakis, Michail S.; Stasinakis, Athanasios S. (September 2019). "Removal of polar micropollutants from domestic wastewater using a methanogenic – aerobic Moving Bed Biofilm Reactor system". Chemical Engineering Journal. 382: 122983. doi:10.1016/j.cej.2019.122983.

- Burton, Franklin; Tchobanoglous, George; Tsuchihashi, Ryujiro; Stensel, H. David; Inc, Metcalf & Eddy (2013-09-03). Wastewater Engineering: Treatment and Resource Recovery. McGraw-Hill Education. ISBN 9780073401188.

- Tang, Kai; Rosborg, Peter; Rasmussen, Emma S; Hambly, Adam; Madsen, Michael; Jensen, Niels M; Hansen, Aviaja A; Sund, Christina; Andersen, Heidi G; Torresi, Elena; Kragelund, Caroline (2021-02-05). "Impact of intermittent feeding on polishing of micropollutants by moving bed biofilm reactors (MBBR)". Journal of Hazardous Materials. 403: 123536. doi:10.1016/j.jhazmat.2020.123536. ISSN 0304-3894. PMID 32823027.

- Casas, Mònica Escolà; Chhetri, Ravi Kumar; Ooi, Gordon; Hansen, Kamilla M. S.; Litty, Klaus; Christensson, Magnus; Kragelund, Caroline; Andersen, Henrik R.; Bester, Kai (2015-10-15). "Biodegradation of pharmaceuticals in hospital wastewater by staged Moving Bed Biofilm Reactors (MBBR)". Water Research. 83: 293–302. doi:10.1016/j.watres.2015.06.042. ISSN 0043-1354. PMID 26164801.

- Mazioti, Aikaterini A.; Stasinakis, Athanasios S.; Psoma, Aikaterini K.; Thomaidis, Nikolaos S.; Andersen, Henrik R. (2017-02-05). "Hybrid Moving Bed Biofilm Reactor for the biodegradation of benzotriazoles and hydroxy-benzothiazole in wastewater". Journal of Hazardous Materials. Special Issue on Emerging Contaminants in engineered and natural environment. 323 (Pt A): 299–310. doi:10.1016/j.jhazmat.2016.06.035. ISSN 0304-3894. PMID 27396311.

- Polesel, Fabio; Torresi, Elena; Loreggian, Luca; Casas, Mònica Escolà; Christensson, Magnus; Bester, Kai; Plósz, Benedek Gy. (2017-10-15). "Removal of pharmaceuticals in pre-denitrifying MBBR – Influence of organic substrate availability in single- and three-stage configurations". Water Research. 123: 408–419. doi:10.1016/j.watres.2017.06.068. ISSN 0043-1354. PMID 28689125.

- Nödler, Karsten; Voutsa, Dimitra; Licha, Tobias (August 2014). "Polar organic micropollutants in the coastal environment of different marine systems". Marine Pollution Bulletin. 85 (1): 50–59. doi:10.1016/j.marpolbul.2014.06.024. ISSN 0025-326X. PMID 25015017.

- Falås, P.; Baillon-Dhumez, A.; Andersen, H. R.; Ledin, A.; la Cour Jansen, J. (2012-03-15). "Suspended biofilm carrier and activated sludge removal of acidic pharmaceuticals". Water Research. 46 (4): 1167–1175. doi:10.1016/j.watres.2011.12.003. ISSN 0043-1354. PMID 22209263.

- Chen, Sheng; Sun, Dezhi; Chung, Jong-Shik (2007-06-01). "Treatment of pesticide wastewater by moving-bed biofilm reactor combined with Fenton-coagulation pretreatment". Journal of Hazardous Materials. 144 (1): 577–584. doi:10.1016/j.jhazmat.2006.10.075. ISSN 0304-3894. PMID 17141410.

- Nogueira, Regina; Melo, Luı́s F; Purkhold, Ulrike; Wuertz, Stefan; Wagner, Michael (January 2002). "Nitrifying and heterotrophic population dynamics in biofilm reactors: effects of hydraulic retention time and the presence of organic carbon". Water Research. 36 (2): 469–481. doi:10.1016/S0043-1354(01)00229-9. hdl:1822/1602. PMID 11827353.