Oakum

Oakum is a preparation of tarred fibre used to seal gaps.[1] Its main traditional applications were in shipbuilding, for caulking or packing the joints of timbers in wooden vessels and the deck planking of iron and steel ships;[1] in plumbing, for sealing joints in cast iron pipe; and in log cabins for chinking. In ship caulking, it was forced into the seams using a hammer and a caulking iron, then sealed into place with hot pitch.[2]

History

The word oakum derives from Middle English okome, from Old English ācumba, from ā- (separative and perfective prefix) + -cumba (akin to Old English camb, 'comb')—literally 'off-combings'.

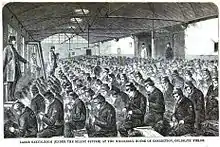

Oakum was at one time recycled from old tarry ropes and cordage,[1] which were painstakingly unravelled and reduced to fibre, termed "picking". The task of picking and preparation was a common occupation in prisons and workhouses,[1] where the young or the old and infirm were put to work picking oakum if they were unsuited for heavier labour. Sailors undergoing naval punishment were also frequently sentenced to pick oakum, with each man made to pick 1 pound (450 g) of oakum a day. The work was tedious, slow and taxing on the worker's thumbs and fingers.[2] In 1862, girls under 16 at Tothill Fields Bridewell had to pick 1 pound (450 g) a day, and boys under 16 had to pick 1 1⁄2 pounds (680 g).[3] Over the age of 16, girls and boys had to pick 1 1⁄2 and 2 pounds (680 and 910 g) per day respectively.[3] The oakum was sold for £4 10s (equivalent to £446 in 2019 in modern money) per hundredweight (100–112 lb, 45–51 kg).[3] At Coldbath Fields Prison, the men's counterpart to Tothill Fields, prisoners had to pick 2 lb (910 g) per day unless sentenced to hard labour, in which case they had to pick between 3 and 6 lb (1.4 and 2.7 kg) of oakum per day.[4]

In modern times, the fibrous material used in oakum comes from virgin hemp or jute. In plumbing and marine applications, the fibers are impregnated with tar or a tar-like substance, traditionally pine tar (also called 'Stockholm tar'), an amber-coloured pitch made from pine sap. Tar-like petroleum by-products can also be used for modern oakum. "White oakum" is made from untarred material, and was chiefly used as packing between brick and masonry in pre-war home and building construction, as its breathability allows moisture to continue to wick and transfer.[1]

Plumbing

Oakum can be used to seal cast iron pipe drains. After setting the pipes together, workers pack oakum into the joints, then pour molten lead into the joint to create a permanent seal. The oakum swells and seals the joint, the "tar" in the oakum prevents rot, and the lead keeps the joint physically tight. Oakum present in cast iron bell/spigot joints may also contain asbestos. Today, modern methods, such as rubber seals (for example, gaskets or o-rings) are more common.[5]

Literature

In Herman Melville's novella Benito Cereno, crew members of a slave ship spend their idle hours picking oakum.

Charles Dickens's novel Oliver Twist mentions the extraction of oakum by orphaned children in the workhouse. The oakum extracted is for use on navy ships, and the instructor says that the children are serving the country.

The Innocents Abroad, a travel book by Mark Twain, also mentions in chapter 37 a "Baker's Boy/Famine Breeder" who eats soap and oakum, but prefers oakum, which makes his breath foul and teeth stuck up with tar.

We tore the tarry rope to shreds

With blunt and bleeding nails;

We rubbed the doors, and scrubbed the floors,

And cleaned the shining rails:

And, rank by rank, we soaped the plank,

And clattered with the pails.

Jack London, in his book The People of the Abyss (1903), mentions picking oakum in the workhouses of London.

References

- Chisholm, Hugh, ed. (1911). . Encyclopædia Britannica. 19 (11th ed.). Cambridge University Press. p. 935.

- Kemp, Peter (1979). The Oxford Companion to Ships & the Sea. Oxford University Press. p. 807. ISBN 978-0-586-08308-6.

- Mayhew, Henry; Binny, John (1862). The Criminal Prisons of London, and Scenes of Prison Life. Volume 3 of The Great Metropolis. London: Griffin, Bohn, and Company. p. 477.

- Mayhew & Binny (1862) p. 312.

- Yates, David (1 February 2005). "The Lost Art of Making Lead Joints". Contractormag.com. Retrieved 6 July 2011.