Ohmic heating (food processing)

Ohmic heating (joule heating, resistance heating, or electroconductive heating) generates heat by passage of electrical current through food which resists the flow of electricity.[1][2][3] Heat is generated rapidly and uniformly in the liquid matrix as well as in particulates, producing a higher quality sterile product that is suitable for aseptic processing.[3][4]

Electrical energy is linearly translated to thermal energy as electrical conductivity increases, and this is the key process parameter that affects heating uniformity and heating rate.[3] This heating method is best for foods that contain particulates suspended in a weak salt containing medium due to their high resistance properties.[2] Ohmic heating is beneficial due to its ability to inactivate microorganisms through thermal and non-thermal cellular damage.[3][5][6]

This method can also inactivate antinutritional factors thereby maintaining nutritional and sensory properties.[5] However, ohmic heating is limited by viscosity, electrical conductivity, and fouling deposits.[1][2][3] Although ohmic heating has not yet been approved by the Food and Drug Administration (FDA) for commercial use, this method has many potential applications, ranging from cooking to fermentation.[3]

Process

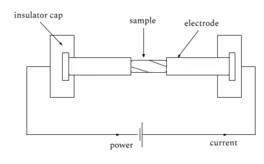

There are different configurations for continuous ohmic heating systems, but the most basic process is outlined in Figure 1.[3] A power supply or generator is needed to produce electrical current.[2] Electrodes, in direct contact with food, pass electric current through the matrix.[2] The distance between the electrodes can be adjusted to achieve the optimum electrical field strength.[2]

The generator creates the electrical current which flows to the first electrode and passes through the food product placed in the electrode gap.[2] The food product resists the flow of current causing internal heating.[3] The current continues to flow to the second electrode and back to the power source to close the circuit.[2] The insulator caps around the electrodes controls the environment within the system.[2]

The electrical field strength and the residence time are the key process parameters which affect heat generation.[3]

Ideal food products

The ideal foods for ohmic heating are viscous with particulates.[3]

- Thick soups

- Sauces

- Stews

- Salsa

- Fruit in a syrup medium

- Milk

- Ice cream mix

- Egg

- Whey

- Heat sensitive liquids

- Soymilk

The efficiency by which electricity is converted to heat depends upon on salt, water, and fat content due to their thermal conductivity and resistance factors.[5] In particulate foods, the particles heat up faster than the liquid matrix due to higher resistance to electricity and matching conductivity can contribute to uniform heating.[3] This prevents overheating of the liquid matrix while particles receive sufficient heat processing.[1] Table 1 shows the electrical conductivity values of certain foods to display the effect of composition and salt concentration.[3] The high electrical conductivity values represent a larger number of ionic compounds suspended in the product, which is directly proportional to the rate of heating.[2] This value is increased in the presence of polar compounds, like acids and salts, but decreased with nonpolar compounds, like fats.[2] Electrical conductivity of food materials generally increases with temperature, and can change if there are structural changes caused during heating such as gelatinization of starch.[3] Density, pH, and specific heat of various components in a food matrix can also influence heating rate.[5]

| Food | Electrical Conductivity (S/m) | Temperature (°C) |

|---|---|---|

| Apple Juice | 0.239 | 20 |

| Beef | 0.42 | 19 |

| Beer | 0.143 | 22 |

| Carrot | 0.041 | 19 |

| Carrot Juice | 1.147 | 22 |

| Chicken meat | 0.19 | 20 |

| Coffee (black) | 0.182 | 22 |

| Coffee (black with sugar) | 0.185 | 22 |

| Coffee (with milk) | 0.357 | 22 |

| Starch solution (5.5%) | ||

| (a) with 0.2% salt | 0.34 | 19 |

| (b) with 0.55% salt | 1.3 | 19 |

| (c) with 2% salt | 4.3 | 19 |

Benefits

Benefits of Ohmic heating include: uniform and rapid heating (>1°Cs−1), less cooking time, better energy efficiency, lower capital cost, and volumetric heating as compared to aseptic processing, [[Canning (food preservation method)|canning]], and PEF.[4] Volumetric heating allows internal heating instead of transferring heat from a secondary medium.[1] This results in the production of safe, high quality food with minimal changes to structural, nutritional, and organoleptic properties of food.[1] Heat transfer is uniform to reach areas of food that are harder to heat.[3] Less fouling accumulates on the electrodes as compared to other heating methods.[2] Ohmic heating also requires less cleaning and maintenance, resulting in an environmentally cautious heating method.[1][3][4]

Effect on microorganisms

Microbial inactivation in ohmic heating is achieved by both thermal and non-thermal cellular damage from the electrical field.[6] This method destroys microorganisms due to electroporation of cell membranes, membrane rupture, and cell lysis.[3][5] In electroporation, excessive leakage of ions and intramolecular components results in cell death.[5] In membrane rupture, cells swell due to an increase in moisture diffusion across the cell membrane.[4] Pronounced disruption and decomposition of cell walls and cytoplasmic membranes causes cells to lyse.[3][5][6]

Effect on nutrition

Decreased processing times in ohmic heating maintains nutritional and sensory properties of foods.[1] Ohmic heating inactivates antinutritional factors like lipoxigenase (LOX), polyphenoloxidase (PPO), and pectinase due to the removal of active metallic groups in enzymes by the electrical field.[5] Similar to other heating methods, ohmic heating causes gelatinization of starches, melting of fats, and protein agglutination.[3] Water-soluble nutrients are maintained in the suspension liquid allowing for no loss of nutritional value if the liquid is consumed.[7]

Limitations

Ohmic heating is limited by viscosity, electrical conductivity, and fouling deposits.[1][2][3] The density of particles within the suspension liquid can limit the degree of processing. A higher viscosity fluid will provide more resistance to heating, allowing the mixture to heat up quicker than low viscosity products.[3]

A food product’s electrical conductivity is a function of temperature, frequency, and product composition.[1][2][3] This may be increased by adding ionic compounds, or decreased by adding non-polar constituents.[1] Changes in electrical conductivity limit ohmic heating as it is difficult to model the thermal process when temperature increases in multi-component foods.[1][2]

Potential applications

The potential applications of ohmic heating range from cooking, thawing, blanching, peeling, evaporation, extraction, dehydration, and fermentation.[3] These allow for ohmic heating to pasteurize particulate foods for hot filling, pre-heat products prior to canning, and aseptically process ready-to-eat meals and refrigerated foods.[2] Prospective examples are outlined in Table 2 as this food processing method has not been commercially approved by the FDA.[2] Since there is currently insufficient data on electrical conductivities for solid foods, it is difficult to prove the high quality and safe process design for ohmic heating.[8] Additionally, a successful 12D reduction for C. botulinum prevention has yet to be validated.[8]

| Applications | Advantages | Food Items |

|---|---|---|

| Sterilisation, heating liquid foods containing large particulates and heat sensitive liquids, aseptic processing | Attractive appearance, firmness properties, pasteurization of milk without protein denaturation | Cauliflower florets, soups, stews, fruit slices in syrups and sauces, ready to cook meals containing particulates, milk, juices, and fruit purees |

| Ohmic cooking of solid foods | The cooking time could be reduced significantly. The centre temperature rises much faster than in conventional heating, improving the final sterility of the product, less power consumption and safer product | Hamburger patties, meat patties, minced beef, vegetable pieces, chicken, pork cuts |

| Space food and military ration | Food reheating and waste sterilization. Less energy consumption for heating food to serving temperature, products in reusable pouches with long shelf life. Additive free foods with good keeping quality of 3 years. | Stew type foods |

| Ohmic thawing | Thawing without increase in moisture content of the product | Shrimp blocks |

| Inactivation of spores and enzymes | To improve food safety and enhance shelf life, increased stability and energy efficiency, Reduced time for inactivation of lipoxygenase and polyphenol oxidase, inactivation of enzymes without affecting flavor | Process fish cake, orange juice, juices |

| Blanching and extraction | Enhanced moisture loss and increase in juice yield | Potato slices, vegetable purees extraction of sucrose from sugar beets, extraction of soy milk from soy beans |

References list

- Ohmic heating in food processing. Ramaswamy, Hosahalli S. Boca Raton, FL: CRC Press. 2014. ISBN 9781420071092. OCLC 872623115.CS1 maint: others (link)

- Varghese, K. Shiby; Pandey, M. C.; Radhakrishna, K.; Bawa, A. S. (October 2014). "Technology, applications and modelling of ohmic heating: a review". Journal of Food Science and Technology. 51 (10): 2304–2317. doi:10.1007/s13197-012-0710-3. ISSN 0022-1155. PMC 4190208. PMID 25328171.

- Fellows, P.J. (2017). Food processing technology. Woodhead Publishing. pp. 831–38. ISBN 978-0-08-101907-8.

- Varzakas, Theodoros; Tzia, Constantina (2015-10-22). Handbook of food processing : food preservation. Varzakas, Theodoros,, Tzia, Constantina. Boca Raton, FL. ISBN 9781498721769. OCLC 924714287.

- Ohmic Heating in food processing. CRC Press. 2014. pp. 93–102. ISBN 978-1-4200-7109-2.

- Varghese, K. Shiby; Pandey, M. C.; Radhakrishna, K.; Bawa, A. S. (2014-10-01). "Technology, applications and modelling of ohmic heating: a review". Journal of Food Science and Technology. 51 (10): 2304–2317. doi:10.1007/s13197-012-0710-3. ISSN 0022-1155. PMC 4190208. PMID 25328171.

- Kaur, Ranvir; Gul, Khalid; Singh, A.K. (2016). "Nutritional impact of ohmic heating on fruits and vegetables A review". Cogent Food & Agriculture. 2 (1). doi:10.1080/23311932.2016.1159000.

- "Kinetics of Microbial Inactivation for Alternative Food Processing Technologies" (PDF). U.S. Food and Drug Administration. May 30, 2018.