Polygonal rifling

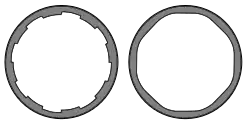

Polygonal rifling (/pəˈlɪɡənəl/ pə-LIG-ə-nəl) is a type of gun barrel rifling where the traditional sharp-edged "lands and grooves" are replaced by less pronounced "hills and valleys", so the barrel bore has a polygonal (usually hexagonal or octagonal) cross-sectional profile. In more modern designs, the Italian firearm manufacturer Sabatti S.P.A. published a press release on September 7, 2017, describing a special type of uncornered polygonal rifling with rounded valleys, dubbed multi-radial rifling.

Polygonal riflings with a larger number of edges have shallower corners, which provide a better gas seal in relatively large diameter bores. For instance, in the pre-Gen 5 Glock pistols, octagonal rifling is used in the large diameter .45 ACP bore, which has an 11.23 mm (0.442 in) diameter, since it resembles a circle more closely than the hexagonal rifling used in smaller diameter bores.[1]

History

Right image: Hexagonal rifling of Le Pétulant (detail).

While polygonal rifling has been around since the earliest days of rifled barrels, it had faded out of use by the time of the early cordite cartridges, mainly due to production issues and poor tolerance towards the newer, more erosive smokeless powder ammunition at the time.

The principle of the polygonal barrel was proposed in 1853 by Sir Joseph Whitworth, a prominent British engineer and entrepreneur. Whitworth experimented with cannons using twisted hexagonal barrels instead of traditional round rifled barrels, and patented the design in 1854. In 1856, this concept was demonstrated in a series of experiments using brass howitzers. The British military, however, rejected Whitworth's polygonal designs. Afterwards, Whitworth adopted the concept on small arms, believing that polygonal rifling could be used to create a more accurate rifled musket to replace the Pattern 1853 Enfield.

During the American Civil War, Whitworth's polygonally rifled Whitworth rifle was successfully used by the Confederate States Army marksmen (known as the Whitworth Sharpshooters) to terrorize Union Army artillery crews. The muzzle-loading Whitworth rifle is often called the "sharpshooter" because of its superior accuracy compared to other rifled muskets of its era (far surpassing the breechloading Sharps rifle used by the Union Army), and is considered one of the earliest examples of a sniper rifle. The Whitworth Sharpshooters killed multiple high-ranking Union officers, most famously Maj Gen. John Sedgwick, who was fatally shot at a range of 1,000 yards (910 m) during the Battle of Spotsylvania Court House.

The last service rifles to use polygonal rifling were the British Lee–Metford rifle, named after its proprietary Metford rifling; and the Japanese Arisaka rifles designed by Col. Arisaka and Col. Nambu. The Lee-Metford rifle turned out to be a failure after the switch to the erosive Cordite proved too much for the smooth and shallow Metford rifling, which had been designed to reduce barrel fouling for black powder ammunition. When the Metford rifling design was dropped, the Lee–Metford became the Lee–Enfield rifle in favour of Enfield type rifling, which was deep-grooved for longer service life. On the other hand, the Arisakas were manufactured extensively for the Imperial Japanese Army from 1897 to 1945 with no excessive rifling erosion problems, as the Japanese having adopted a better, non-erosive rifle powder.

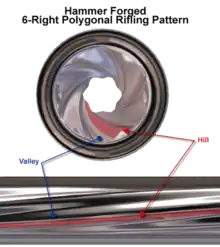

During World War II, polygonal rifling emerged again in the German MG 42 general-purpose machine guns, as an outgrowth of a cold-hammer forging process developed by German engineers prior to the outbreak of the war. The process addressed the need to produce large quantities of more durable gun barrels in less time than those produced with traditional methods,[2] as the MG 42's infamously fast rate of fire tended to overheat the barrel quickly and thus warranted frequent barrel changes. The MG 42 successor, the Rheinmetall MG 3 machine gun, can also have polygonal rifling.

Heckler & Koch was the first manufacturer to begin using polygonal rifling in modern small arms like the G3A3 battle rifle and several semi automatic hunting rifles like the HK SL7.[3] Companies that utilize this method today include Tanfoglio, Heckler & Koch, Glock (Gen 1-4), Magnum Research, Česká Zbrojovka, Kahr Arms, Walther and Israel Weapon Industries. Polygonal rifling is usually found only in pistol barrels, and is less common in rifles; however, some extremely high end precision rifles like the Heckler & Koch PSG1 and its Pakistani variant PSR-90, and the LaRue Tactical Stealth System sniper rifle use polygonal bores.

The term "polygonal rifling" is fairly general, and different manufacturers employ varying polygonal rifling profiles. H&K, CZ and Glock use a female type of polygonal rifling similar to the bore shown above right. This type has a smaller bore area than the male type of polygonal rifling designed and used by Lothar Walther. Other companies such as Noveske (Pac Nor) and LWRC use a rifling more like the conventional rifling, with both of each land's sides being sloped but having a flat top and defined corners; this type of rifling is more a canted land type of rifling than polygonal rifling.

Advantages

A number of advantages are claimed by the supporters of polygonal rifling. These include:

- Not compromising the barrel's thickness in the area of each groove as with traditional rifling, and also less sensitive to stress concentration-induced barrel failure.

- Providing a better gas seal around the projectile as polygonal bores tend to have shallower, smoother edges with a slightly smaller bore area, which translates into more efficient seal of the combustion gases trapped behind the bullet,[4] slightly greater (consistency in) muzzle velocities and slightly increased accuracy.[1]

- Less bullet deformation, resulting less frictional resistance when the bullet travels through the barrel, which helps to increase muzzle velocity. The lack of sharp surface deformation on the bullet (rifling marks) also reduce drag in flight.

- Reduced buildup of copper or lead within the barrel, as there are no sharp rifling edges to "shred" into the bullet surface and no pronounced corners that can accumulate foulings difficult to clean, which results in easier maintenance. The reduced fouling also theoretically translates to a simpler "copper equilibrium" profile, which is potentially beneficial to accuracy.

- Prolonged barrel life, as the thermomechanical stress upon the riflings are spread over a larger area, hence less wear over time.

However, precision target pistols such as those used in Bullseye and IHMSA almost universally use traditional rifling, as do target rifles. The debate among target shooters is almost always one of cut vs. button rifled barrels, as traditional rifling is dominant. Polygonal rifled barrels are used competitively in pistol action shooting, such as IDPA and IPSC competitions.

Part of the difference may be that most polygonal rifling is produced by hammer forging the barrel around a mandrel containing a reverse impression of the rifling. Hammer forging machines are tremendously expensive, far out of the reach of custom gunsmiths (unless they buy pre-rifled blanks), and so are generally only used for production barrels by large companies. The main advantage of a hammer forging process is that it can rifle, chamber, and contour a bored barrel blank in one step. First applied to rifling in Germany in 1939, hammer forging has remained popular in Europe, but was only later used by gunmakers in the United States. The hammer forging process produces large amounts of stress in the barrel that must be relieved by careful heat treatment, a process that is less necessary in a traditionally cut or button rifled barrel. Due to the potential for residual stress causing accuracy problems, precision shooters in the United States tend to avoid hammer forged barrels, and this limits them in the type of available rifling. From a practical standpoint, any accuracy issues resulting from the residual stresses of hammer forging are extremely unlikely to be an issue in a defense or service pistol, or a typical hunting rifle.

Forensic firearms examination

Polygonal rifling prevents the forensic firearms examiner from microscopically measuring the width of land and groove impressions (so-called "ballistic fingerprinting") because the polygonal riflings have a rounded profile instead of well-defined rectangular edges, which causes few noticeable surface deformations. In the FBI GRC file, the land and groove widths for these firearms are listed as 0.000. However, it must be noted that forensic identification of firearms [in court-cases, etc.] is based on microscopic examination of tooling marks on the surface of the bore, produced by the manufacturing process and modified by the drag of bullet jackets on that same surface. Thus the bore surface of individual firearms is always unique.[5]

Lead bullets and polygonal rifling

The Austrian firearm manufacturer Glock advises against using bare lead bullets (i.e. with no jacketing) in their polygonally rifled barrels, which has led to a widespread belief that polygonal rifling is not compatible with lead bullets. Firearms expert and barrel maker, the late Gale McMillan, has also commented that lead bullets and polygonal rifling are not a good mix. Neither H&K nor Kahr explicitly recommend against lead bullets in their polygonal rifled barrels, suggesting that there might be an additional factor involved in Glock's warning. Kahr warns that lead bullets can cause additional fouling[6] and recommends special attention to cleaning after their use. While H&K doesn't insist on a copper jacket, at least one well-documented catastrophic incident in an H&K pistol[7] may be related to this issue. Furthermore, Dave Spaulding, well-known gun writer, reported in the February/March 2008 issue of Handguns Magazine that when he queried H&K about their polygonally rifled barrels that they commented: "It has been their experience that polygonal rifling will foul with lead at a greater rate than with conventional rifling."

One suggestion of what the "additional factor involved in Glock's warning" might be is that Glock barrels have a fairly sharp transition between the chamber and the rifling, and this area (known as the "throat") is prone to lead buildup if bare lead bullets are used. This buildup may result in failures to fully return to battery, causing the gun to fire with the case not adequately supported by the chamber and the breech not fully locked, leading to a potentially dangerous case failure. However, since this sharp transition is found on most autopistols this speculation is of limited value. The sharp transition or "lip" at the front of the chamber is required to headspace the cartridge in most autopistols.

Another possible explanation is that there are different "species" of polygonal rifle and perhaps Glock's peculiar style of polygonal rifling may be more prone to lead fouling than the particular styles employed in the H&K and Kahr barrels.

"Leading" is the buildup of lead in the bore that happens in nearly all firearms firing high velocity lead bullets. This lead buildup must be cleaned out regularly, or the barrel will gradually become constricted resulting in higher than normal bore pressures. In the extreme case, increased discharge pressures can overwhelm the material strength of the barrel and result in a catastrophic failure, and the gun blows open in the shooter's hand causing severe injuries.

See also

References

- Barrel History Archived 2010-04-20 at the Wayback Machine

- Barrels and Bullets: Conventional Versus Polygonal Rifling by Dennis Cantrell 06/08/2010

- SL7 Polygonlauf, Vielflächenlauf by Lutz Möller (German)

- Peter Alan Kasler - Glock: The New Wave in Combat Handguns, p. 138

- "National Institute of Justice Firearm Examiner Training".

- "Questions and Answers: Kahr Pistol". thegunzone.com. 2007. Retrieved 2009-05-13.

- "Learning About Shooting, No. 01… Why not to shoot lead handloads through a barrel with polygonal rifling (Invalid reference 2017-05-28)". April 2002. Archived from the original on 2008-10-10. Retrieved 2009-05-13.

External links

- Glockmeister FAQ, with information on lead bullets in Glock firearms.

- The Gun Zone 2001 e-mail questions, with information on cast bullets in Glock and H&K handguns.

- Barrel making FAQ, with information on methods of making and rifling barrels

- 6mmBR barrel FAQ, covers new polygonal profile button rifled barrels

- Polygonal Rifling, A comment from Gale McMillan about lead bullets and polygonal rifling.