Quadruple glazing

Quadruple glazing (quadruple-pane insulating glazing) is a type of insulated glazing comprising four glass panes, commonly equipped with low emissivity coating and insulating gas in the cavities between the glass panes. Quadruple glazing is a subset of multipane (multilayer) glazing systems. Multipane glazing with up to six panes is commercially available.[1] Multipane glazing improves comfort, reduces recurring expense and can reduce greenhouse gas emissions by minimising heating and cooling demand. Different administrative districts (country/state/city etc) mandate different energy efficiency level. Quadruple glazing may be required to achieve the desired energy efficiency levels in the arctic regions,[2] or to allow for higher glazing ratios in curtain walling without increasing winter heat loss. Quadruple glazing allows building glazing elements to be designed free of modulated external sun-shading as variable solar gain no longer provides energy efficiency improvement at low thermal transmittance achievable with quadruple and other multipane glazing.[3] There are numerous buildings built with ageing triple glazing in Nordic countries that are in need of renovation where multipane glazing is a solution of choice.[4]

]

]

Special features of ultra-low U-value glazed buildings

With quadruple glazing, the center of panel U-value (Ug) of 0,33 W/(m2K) [R-value 17] is readily achievable.[5] With six-pane glazing Ug value as low as 0,24 W/(m2K) [R-value 24] was reported.[1] With U-value that low, new, not obvious options arise.

Energy efficient buildings without modulated sun shading. To save the cost, with overall window thermal transmittance lower than about 0,4 W/(m2K) it is possible to abandon, otherwise common, modulated external shading. It has been shown that at such low window U-values, glazing with moderate solar gain performs comparably to glazing of comparable U-value with variable external shading and high solar gain.[3] This is because with improved overall U-values building's heating demand diminishes and as a consequence solar heat gain loses much of its utility.

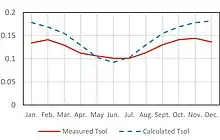

Pronounced seasonal-dependence of the solar gain. Due to incidence-angle-dependent Fresnel reflections, the optical characteristics of multipane glazing, also notably vary seasonally. As the sun's average elevation varies throughout the year, the effective solar gain tends to be meaningfully less in the summer.[1] The effect is also visible to an extent with a naked eye.

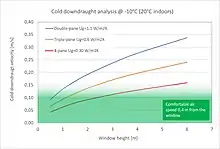

Comfort of living. Limited or no contact with the environment and living and working with minimal daylight are often a consequence of modulated sun shading. On the contrary, multipane glazing offers uninterrupted contact with the environment. A low U-value maintains inside glass temperatures at an equable level throughout the year. Furthermore, an unprecedented winter downdraught-free zone is created in the vicinity of the panoramic glazing.[1]

Nearly zero-heating building. Already in 1995, it was predicted that with a glazing U-value of 0,3 W/(m2K) zero-heating building could be realized.[6] It has also recently been shown[3] that for glazed buildings with system U-values as low as 0,3 W/(m2K) the heating demand might be decreased to nearly zero. The remaining cooling demand can be favorably synchronized with solar radiation, where maximum photovoltaic generation nearly coincides with the maximum power needed for cooling. In this way, the building would not need a fossil winter power reserve and it would not need seasonal energy storage.[1]

Multipane glazing engineering

Quadruple or multipane glazing is often designed with thinner intermediate glass panes to save weight.[7] To prevent intermediate panes from thermal stress cracking it is sometimes required to use heat-strengthened glass.[7][5] With more than three glass panes, special care must be taken of the spacer and sealant[8] temperatures as intermediate glass panes in contact with these glazing elements can readily exceed design temperature limits of respective materials due to solar radiation (irradiance) heating. Solar irradiance heating of intermediate glass panes increases substantially with an increased number of glass panes.[1][9] Multipane glazing must be carefully designed regarding the climatic loading which is higher with the increasing number of glass panes. Special measures for handling glass bulging effect,[10] which occurs due to insulating gas heating and expanding, might be employed.[1] Finite element analysis is often used to calculate appropriate glass sheets' strengths.

See also

References

- Kralj, Aleš; Drev, Marija; Žnidaršič, Matjaž; Černe, Boštjan; Hafner, Jože; Jelle, Bjørn Petter (May 2019). "Investigations of 6-pane glazing: Properties and possibilities". Energy and Buildings. 190: 61–68. doi:10.1016/j.enbuild.2019.02.033.

- Krick, Benjamin. "Optimum glazing in the regions of Europe considering the embedded energy" (PDF). Passive House Institute. Passive House Institute. Retrieved 3 May 2019.

- Vanhoutteghem, Lies; Skarning, Gunnlaug Cecilie Jensen; Hviid, Christian Anker; Svendsen, Svend (September 2015). "Impact of façade window design on energy, daylighting and thermal comfort in nearly zero-energy houses" (PDF). Energy and Buildings. 102: 149–156. doi:10.1016/j.enbuild.2015.05.018.

- Kristiansen, Øyvind Meyer. "Höegh Eiendom først i Norge med innovativ fasadeløsning". Enova. ENOVA. Retrieved 23 May 2019.

- Chmúrny, Ivan (January 2016). "Triple or Quadruple Glazing?". Applied Mechanics and Materials. 820: 242–247. doi:10.4028/www.scientific.net/AMM.820.242. S2CID 111693176.

- Feist, Wolfgang (1995). Erfahrungen mit Häusern ohne aktives Heizsystem. Darmstadt: IBK-Institut für das Bauen mit Kunststoffen.

- "Quadruple insulated glass unit". MEM4WIN. MEM4WIN. Retrieved 16 Feb 2020.

- Starman, Bojan; Maček, Andraž; Rus, Primož; Obid, Štefan; Kralj, Aleš; Halilovič, Miroslav (19 February 2020). "Primary Seal Deformation in Multipane Glazing Units". Applied Sciences. 10 (4): 1390. doi:10.3390/app10041390.

- Grynning, Steinar; Jelle, Bjørn; Gustavsen, Arild; Gao, Tao; Time, Berit (2016). Multilayer Glazing Technologies: Key Performance Parameters and Future Perspectives. Aalborg, Denmark: CLIMA 2016 - Proceedings of the 12th REHVA World Congress, Vol. 2. pp. Article no. 187. Retrieved 3 May 2019.

- Anderson, Martin; Simon, Nilsson (2014). BULGING OF INSULATINGGLASS UNITS - Numerical and Experimental Analysis (PDF). Lund, Sweden: Lund University.

External links

| Wikimedia Commons has media related to Curtain walls. |