Ramberg–Osgood relationship

The Ramberg–Osgood equation was created to describe the non linear relationship between stress and strain—that is, the stress–strain curve—in materials near their yield points. It is especially applicable to metals that harden with plastic deformation (see work hardening), showing a smooth elastic-plastic transition. As it is an phenomenological model, it is it important to check the fit of the model with actual experimental data for the particular material of interest.

In its original form, the equation for strain (deformation) is[1]

here

- is strain,

- is stress,

- is Young's modulus, and

- and are constants that depend on the material being considered. In this form K and n are not the same as the constants commonly seen in the Hollomon equation.[2]

The equation is essentially assuming the elastic strain portion of the stress strain curve, , can be modeled with a line, while the plastic portion, , can be modeling with a power law. The elastic and plastic components are summed to find the total strain.

The first term on the right side, , is equal to the elastic part of the strain, while the second term, , accounts for the plastic part, the parameters and describing the hardening behavior of the material. Introducing the yield strength of the material, , and defining a new parameter, , related to as , it is convenient to rewrite the term on the extreme right side as follows:

Replacing in the first expression, the Ramberg–Osgood equation can be written as

Hardening behavior and yield offset

In the last form of the Ramberg–Osgood model, the hardening behavior of the material depends on the material constants and . Due to the power-law relationship between stress and plastic strain, the Ramberg–Osgood model implies that plastic strain is present even for very low levels of stress. Nevertheless, for low applied stresses and for the commonly used values of the material constants and , the plastic strain remains negligible compared to the elastic strain. On the other hand, for stress levels higher than , plastic strain becomes progressively larger than elastic strain.

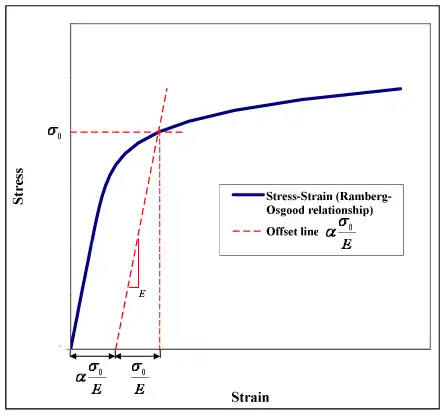

The value can be seen as a yield offset, as shown in figure 1. This comes from the fact that , when .

Accordingly, (see Figure 1):

- elastic strain at yield =

- plastic strain at yield = = yield offset

Commonly used values for are ~5 or greater, although more precise values are usually obtained by fitting of tensile (or compressive) experimental data. Values for can also be found by means of fitting to experimental data, although for some materials, it can be fixed in order to have the yield offset equal to the accepted value of strain of 0.2%, which means:

Alternative Formulations

Several slightly different alternative formulations of the Ramberg-Osgood equation can be found. As the models are purely empirical, it is often useful to try different models and check which has the best fit with the chosen material.

The Ramberg-Osgood equation can also be expressed using the Hollomon parameters[3] where is the strength coefficient (Pa) and is the strain hardening coefficient (no units).[4]

Alternatively, if the yield stress, , is assumed to be at the 0.2% offset strain, the following relationship can be derived.[5]

References

- Ramberg, W., & Osgood, W. R. (1943). Description of stress–strain curves by three parameters. Technical Note No. 902, National Advisory Committee For Aeronautics, Washington DC.

- "Mechanical Properties of Materials | MechaniCalc". mechanicalc.com. Retrieved 2020-05-27.

- Hollomon, J. R. (1945). "Tensile Deformation". Transaction of AIME. 162: 268–277.

- Gadamchetty, Geethanjali; Pandey, Abhijeet; Gawture, Majnoo (2016-01-05). "On Practical Implementation of the Ramberg-Osgood Model for FE Simulation". SAE International Journal of Materials and Manufacturing. 9 (1): 200–205. doi:10.4271/2015-01-9086. ISSN 1946-3987.

- Hill, H. N. (1944). Determination of stress-strain relations from "offset" yield strength values. National Advisory Committee for Aeronautics. OCLC 647978489.