Trussed Concrete Steel Company

The Trussed Concrete Steel Company was a company founded by Julius Kahn, an engineer and inventor. The company manufactured prefabricated products for reinforced concrete beams and steel forms for building reinforced concrete floors and walls. Kahn invented and patented a unique new technology reinforcement system of construction called the Kahn System that was stronger, more economical, and lighter than the existing old school technology used up to that point to construct buildings. The old method was to use plain straight smooth steel beams or loose rods or stirrups in concrete beams and floors. Kahn's new technology improved system used 45 degree tab flanges or "wings" permanently attached on steel beams that distributed the tension stress for overall improvement in strength of reinforced concrete.[1]

| |

| Industry | Steel |

|---|---|

| Fate | Merged |

| Successor | Republic Steel |

| Founded | 1903 |

| Defunct | 1937 |

| Headquarters | |

Key people | |

| Products | |

Number of employees | approx. 10,000 |

| Parent | Trussed Concrete Steel |

History

Kahn founded in 1903 the Trussed Concrete Steel Company in a small Detroit building with a dozen employees for manufacturing the specially designed steel products for reinforcement in concrete beams and walls.[2][3] Kahn became its first president.[4] The company had its headquarters in Detroit, Michigan. The main manufacturing factory for the steel products was located in Youngstown, Ohio, after being in Detroit at first from 1903–1906. In 1906 a one-acre industrial site was developed in Youngstown at a cost of a million dollars. The new steel factory officially opened its doors for business in May 1907 with 100 employees. The Youngstown factory was developed because of its easy access to raw materials needed for steel production.[2] The headquarters for Trussed Concrete Steel Company was located in Detroit at the northeast corner of Lafayette Boulevard and Wayne Street, in a new eight-story skyscraper built by Albert Kahn Associates in 1907.[5] The building was the first office building in Detroit built from concrete and was later known as the Owen Building.[6] The Packard automobile factory plant building number 10, originally designed in 1903–05, was the first time an automobile factory was constructed in the United States using reinforced concrete.[7][8][9][10][11][12][13][14]

< = >

< = >

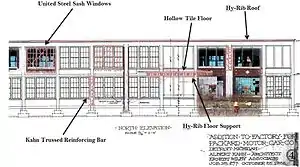

The full company name of "Trussed Concrete Steel Company" was difficult for the public so it was shortened to "Truscon".[2][15] However, it did not officially change its name to Truscon Steel Company until 1918.[1] Truscon produced their steel building materials including high ribbed steel forms for floors, ceilings, and walls. Kahn's new technology became a standard throughout the building industry.[16] The company products had been used in over 15,000 structures worldwide by 1914.[17] The factory developed derivatives from the initial Kahn Bar parent that the company was based on and manufactured these new steel reinforcement products from 1907 through 1914 for concrete construction of industrial buildings. The company expanded their product lines again in 1915 to include prefabricated buildings in kit form ready for assembly on site.[18] It made products under the brand names of Hy-Rib, Rib Lath, Kahn Bars, Rib Bars, Rib Metal, and United Steel Sash.[19]

Kahn's system of reinforced concrete beams allowed for long span open floor room space, larger than could be provided using wood construction. This allowed solid-slab construction where shearing stresses could be maintained better.[20] Large walls with few supports meant generous-sized windows could be installed on exterior walls to provide better natural sunlight and ventilation. This led to the design in factories known as the "Kahn Daylight System." [21] The company had a wide selection of steel products for reinforcement and prefabricated them to customer needs and specifications. Some products were collapsible column reinforcements, steel joists, and standardized steel forms.[20] The company had several divisions. One division was Truscon Laboratories, based in Detroit. A 1924 maintenance book from Truscon gave instructions on how to maintain a large industrial building and illustrated their "graduate engineers" as white-coated scientists.[22]

Kahn, with his brother Albert, capitalizing on the compatible relationship between steel and concrete, exported their prefabricated products to European and Asian markets. Their products became the dominant prefabricated reinforcements exported to foreign markets between World War I and World War II, competing against French and Chinese products.[20] The company had agent representatives in Central America, South America, Europe and Asia. [20] The earliest British examples of the use of the Kahn system of reinforced concrete to build factories was in 1913 for the Arrol-Johnson Motor Company and the Albion Motor Car Company.[21] The company developed a manufacturing factory about 1915 in Japan to manufacture its products for the Asian market. It eventually sold its interest to Mitsui Company in 1933.[3]

The company capitalized on its proprietary system for 20 years from 1903 and had much success in getting most of the market share worldwide. The Kahn Bar patent expired and others then developed non-proprietary systems of reinforced concrete. By 1930 the Kahn System of reinforced concrete became obsolete compared to more modern techniques of reinforcement that were more economical to manufacture. In 1937 the company was bought out by Republic Steel and Julius Kahn was vice-president of this new entity.[2][17]

Publicity

It was discovered after the 1906 San Francisco earthquake most buildings were destroyed either by the earthquake or the aftermath fire, except those built with the Kahn System by the Trussed Concrete Steel Company.[23] The engineering services of the company was specified in many cases upon rebuilding commercial buildings in San Francisco.[17] The company received additional unintentional beneficial publicity when earthquakes occurred in Calabria in 1905, Messina in 1907, Jamaica in 1907, and the 1911 Philippines Mount Taal volcano eruption.[17]

Truscon steel products

According to a 1910 specification booklet published by Trussed Concrete Steel Company, the following were some products the company manufactured and sold.[24]

- Kahn Trussed Bars—for reinforcing concrete beams, girders, joists and arches

- Rib Metal—for reinforcing slabs and walls

- Column Hooping—for reinforcing conduits

- Cup-Bars—for reinforcing columns

- Hy-Rib—for reinforcing floors, roofs, walls, and ceilings

- Rib Lath—a clinching material for plaster and stucco to adhere to

- Rib Studs—to provide openings for the passage of conduits, wires, and plumbing

- Window Casements—fireproof windows for factories and industrial buildings

- Floor and partition tile

- Building block and joist hangers

- Stair treads and post caps

- Floor enamel and foundation coats

- Waterproofing paste

- Wall finishes and coatings

- Truscon Standard Buildings in kit form.[25]

- An example is a gas station that was assembled on site from the pre-designed already-made parts.

See also

| Wikimedia Commons has media related to Trussed Concrete Steel Company. |

References

- Cody 2005, p. 37.

- Bucci 2002, p. 33.

- "Julius Kahn Dies at Home". Youngstown Vindicator. November 5, 1942. p. 1, col. 3.

- Chilton 1920, p. 67.

- Bucci 2002, p. 146.

- Ferry 1970, p. 13.

- Hildebrand 1974, p. 31. "Thus Plant Number Ten represented a clear advance in factory construction for Packard and for the automobile industry in general, as it was the first automobile plant to be built of reinforced concrete."

- Sedlar 2013, p. 31. "The Packard #10 building was the first to utilize reinforced concrete with Julius Kahn's Kahn Bar but also as previously discussed, the full range of steel building products from the Trussed Concrete Steel Company."

- Kahn, Albert (January 14, 2004). Bund, Sally Linvill (ed.). "Albert Kahn papers". Bentley Historical Library. University of Michigan. Retrieved July 30, 2014.

Kahn's first factory built of reinforced concrete in Detroit was Building Number 10 for the Packard Motor Company (1905).

- Nelson 1939, p. 10. "The first reinforced concrete factory in the country, designed by Albert Kahn, made its appearance in 1905."

- Olsen 2002, p. 38 "In 1905 Kahn and Julius designed the Packard Plant number 10 using steel-reinforced concrete, the first such application for an industrial plant".

- Smith 1994, p. 59 "Together they built ten works buildings for Packard, Plant No. 10 (1905) being the first reinforced concrete structure in the automobile industry, notable for its lengths of open space between columns and the good lighting from near-floor-to-ceiling windows".

- Darley 2003, p. 82 "The example of flexibility that he chose to illustrate was Albert Kahn's building of 1905 for Packard in Detroit, building No. 10, the first to use the Kahn reinforced concrete system successfully, which has been effortlessly extended by an additional two stories in 1911".

- Baldwin 2002, p. 197 "His first major corporate client was the Packard Motor Car Company, headed by Henry B. Joy, from whom Kahn eventually designed ten buildings, culminating in Detroit's first large auto plant, the first reinforced concrete auto factory in America".

- Derby 1930, p. 36.

- Marsh 1909, p. 69.

- Sedlar, Frank (June 24, 2013). "Engineering Industrial Architecture: Albert Kahn and the Trussed Concrete Steel Company" (PDF). 2012–2013 MLibrary Undergraduate Research Award Maize Award for Single-Term Projects. University of Michigan.

- Butler 1921, p. 726.

- Truscon 1917, p. 4.

- Cody 2005, p. 38.

- Skinner 1997, p. 13.

- Hughes, Allen & Hecht 2001, p. 142.

- Estes 1911, p. 20-34.

- Truscon 1917, p. 4-5.

- Truscon (1920). Standard buildings built with standard stock units: Truscon standard buildings. Trussed Concrete Steel Company. Retrieved July 1, 2014.

Bibliography

- Baldwin, Neil (2002). Henry Ford and the Jews: The Mass Production of Hate. Public Affairs. ISBN 978-1-58648-163-6.CS1 maint: ref=harv (link)

- Bucci, Federico (2002). Albert Kahn: Architect of Ford. Princeton Architectural Press. ISBN 978-1-56898-343-1.CS1 maint: ref=harv (link)

- Butler, Joseph Green (1921). History of Youngstown and the Mahoning Valley, Ohio. American Historical Society. LCCN 21007821.CS1 maint: ref=harv (link)

- Chilton (1920). Iron Age. 105. Chilton Company. ISSN 0021-1508. LCCN 48011736.CS1 maint: ref=harv (link)

- Cody, Jeffrey W. (2005). Exporting American Architecture 1870–2000. Routledge. ISBN 978-1-135-80487-9.CS1 maint: ref=harv (link)

- Darley, Gillian (2003). Factory. Reaktion Books. ISBN 978-1-86189-155-6.CS1 maint: ref=harv (link)

- Derby, George (1930). The National Cyclopaedia of American Biography. 33. J. T. White & Company. Retrieved July 30, 2014 – via HathiTrust.CS1 maint: ref=harv (link)

- Estes, Lewis Alden (1911). Earthquake-Proof Construction: A Discussion of the Effects of Earthquakes on Building Construction with Special Reference to Structures of Reinforced Concrete. Trussed Concrete Steel Co.CS1 maint: ref=harv (link)

- Ferry, W. Hawkins (1970). The Legacy of Albert Kahn. Detroit: Wayne State University Press. ISBN 0-8143-1889-4.CS1 maint: ref=harv (link)

- Hildebrand, Grant (1974). Designing for industry: the architecture of Albert Kahn. The MIT Press. ISBN 978-0-262-08054-5.CS1 maint: ref=harv (link)

- Hughes, Agatha C.; Allen, Michael Thad; Hecht, Gabrielle (2001). Technologies of Power: Essays in Honor of Thomas Parke Hughes and Agatha Chipley Hughes. MIT Press. ISBN 978-0-262-51124-7.CS1 maint: ref=harv (link)

- Marsh, Charles (1909). Reinforced Concrete. New York: D. Van Nostrand. Retrieved July 7, 2014 – via HathiTrust.CS1 maint: ref=harv (link)

- Nelson, George (1939). Industrial architecture of Albert Kahn, Inc. Architectural Book Publishing Company. LCCN 39005868.CS1 maint: ref=harv (link)

- Olsen, Byron (2002). The American Auto Factory. MotorBooks International. ISBN 978-0-7603-1059-5.CS1 maint: ref=harv (link)

- Skinner, Joan S. (1997). Form and Fancy: Factories and Factory Buildings by Wallis, Gilbert & Partners, 1916–1939. Liverpool University Press. ISBN 978-0-85323-612-2.CS1 maint: ref=harv (link)

- Smith, Terry (1994). Making the Modern: Industry, Art, and Design in America. University of Chicago Press. ISBN 978-0-226-76347-7.CS1 maint: ref=harv (link)

- Truscon (1917). Hy-Rib Handbook; roofs—floors—walls—sidings—partitions—ceilings—furring—silos—tanks—conduits, concrete without forms. Youngstown, Ohio: Trussed Concrete Steel Company. OCLC 33111897.CS1 maint: ref=harv (link)

Further reading

- Banham, Reyner (1989). A Concrete Atlantis: U.S. Industrial Building and European Modern Architecture 1900–1925. Cambridge, MA: MIT Press.

- Dixon, Jennifer (December 2, 2012). "Asbestos, Reinforced Concrete Would Make Demolishing Packard Plant Expensive, Lengthy". Detroit Free Press.

- Giedion, Sigfried (1944). "American Development". Journal of Space, Time and Architecture: 257–290.

- Kahn, Albert (1921). Albert Kahn, Architect, Detroit Michigan. New York: Architectural Catalog Co.

- Kahn, Albert (November 18, 1918). Reinforced Concrete.

- Kahn, Albert (1924). Reinforced Concrete Architecture These Past Twenty Years. 20th Anniversary of the American Concrete Institute.

- Kahn, Julius (August 18, 1903). Concrete and Metal Construction. United States Patent Office. 736602.

- Marquis, Albert Nelson (1914). "Biography of Julius Kahn". The Book of Detroiters: A Biographical Dictionary of Leading Living Men of the City of Detroit. Chicago: A.N. Marquis.

- Meister, Chris (March 2013). "Albert Kahn's Partners in Industrial Architecture". Society of Architectural Historians. 72: 78–95. doi:10.1525/jsah.2013.72.1.78.

- Nelson, George. "Industrial Architecture of Albert Kahn Inc". Republic Steel Corporation Audiovisual Collection. OhioHistory. Missing or empty

|url=(help)