Westgard rules

The Westgard rules are a set of statistical patterns, each being unlikely to occur by random variability, thereby raising a suspicion of faulty accuracy or precision of the measurement system. They are used for laboratory quality control, in "runs" consisting of measurements of multiple samples. They are a set of modified Western Electric rules, developed by James Westgard and provided in his books and seminars on quality control.[1] The rules are:[2]

| Rule | Criteria | Suspected | Example |

|---|---|---|---|

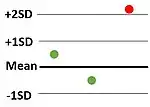

| 12s | One measurement exceeds 2 standard deviations either above or below the mean of the reference range. | Inaccuracy and/or imprecision |  |

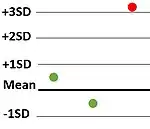

| 13s | One measurement exceeds 3 standard deviations either above or below the mean of the reference range. | Inaccuracy and/or imprecision |  |

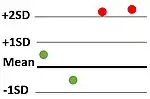

| 22s | 2 consecutive measurements exceed 2 standard deviations of the reference range, and on the same side of the mean. | Inaccuracy. |  |

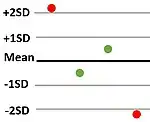

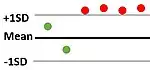

| R4s | Two measurements in the same run have a 4 standard deviation difference (such as one exceeding 2 standard deviations above the mean, and another exceeding 2 standard deviations below the mean). | Imprecision. |  |

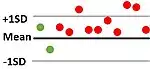

| 41s | 4 consecutive measurements exceed 1 standard deviation on the same side of the mean. | Inaccuracy. |  |

| 10x | 10 consecutive measurements are on the same side of the mean. | Inaccuracy. |  |

The recommended consequences when any of the above patterns occur is to reject the run, except for the rule of 12s (top in table), which serves as a warning and a recommendation of careful inspection of the data.[2]

See also

References

- Ofer Harel; Enrique F. Schisterman; Albert Vexler & Marcus D. Ruopp (July 2008). "Monitoring Quality Control: Can We Get Better Data?". Epidemiology. 19 (4): 621. doi:10.1097/ede.0b013e318176bfb2. PMC 2625303. PMID 18496467.

- Heidi Hanes. "Westgard Rules - Guidelines". SMILE, Johns Hopkins University. Review date: 1 April 2020

External links

This article is issued from Wikipedia. The text is licensed under Creative Commons - Attribution - Sharealike. Additional terms may apply for the media files.