Ducted propeller

A ducted propeller, also known as a Kort nozzle, is a marine propeller fitted with a non-rotating nozzle. It is used to improve the efficiency of the propeller and is especially used on heavily loaded propellers or propellers with limited diameter. It was developed first by Luigi Stipa (1931) and later by Ludwig Kort (1934). The Kort nozzle is a shrouded propeller assembly for marine propulsion. The cross-section of the shroud has the form of a foil, and the shroud can offer hydrodynamic advantages over bare propellers, under certain conditions.

Advantages are increased efficiency at lower speeds (<10 knots), better course stability and less vulnerability to debris. Downsides are reduced efficiency at higher speeds (>10 knots), course stability when sailing astern, and increase of cavitation. Ducted propellers are also used to replace rudders.

History

Luigi Stipa[1] in 1931 and later Ludwig Kort (1934)[2] demonstrated that an increase in propulsive efficiency could be achieved by surrounding the propeller with a foil-shaped shroud in the case of heavily loaded propellers. A "Kort Nozzle" is referred to as an accelerating nozzle and is generally a MARIN 19A profile[3][4] or a MARIN 37 profile.[3][5]

Advantages and disadvantages

Kort nozzles or ducted propellers can be significantly more efficient than unducted propellers at low speeds, producing greater thrust in a smaller package. Tugboats and fishing trawlers are the most common application for Kort nozzles as highly loaded propellers on slow moving vessels benefit the most. Nozzles have the additional benefits of reducing paddlewheel-effect (e.g. the tendency of a right-hand wheel to back to the left) and reduce bottom suction while operating in shallow water.

The additional shrouding adds drag, however, and Kort nozzles lose their advantage over propellers at about ten knots (18.5 km/h).

Kort nozzles may be fixed, with directional control coming from a rudder set in the water flow, or pivoting, where their flow controls the vessel's steering.

Shrouding of this type is also beneficial to navigation in ice fields since it protects the propeller tips to some extent. However, ice or any other floating object can become jammed between the wheel and nozzle, locking up the wheel. Fouled wheels in Kort nozzles are much more difficult to clear than open wheels.

A research paper by Bexton et al. (2012)[6] concluded that ducted propellers were the likely cause of fatal injuries of seals in the northeastern Atlantic. The authors hypothesized that the seals were drawn through the nozzle and past the rotating propeller blades, incurring curvilinear lacerations to skin and muscle tissue. This type of injury has come to be known as a "corkscrew" injury. The authors also comment that other animals, including harbour porpoises, have been seen to exhibit similar injuries.

Types

There are two types of ducts; accelerating and decelerating. With accelerating ducts, the inflow velocity and efficiency of the propeller is increased. This is the type that is used on heavily loaded propellers or propellers with limited diameter. As Ludwig Kort performed extensive research on this type, it is often called a "Kort nozzle".

With the second type, the inflow velocity is reduced, whereby pressure is increased, reducing cavitation. This is called a pump-jet, especially in combination with fixed blades or variable stators.

.svg.png.webp)

MARIN has done extensive research on ducted propellers. Many of the used profiles are based on the NACA airfoils of which the NACA 4415 has very good characteristics. Most commonly used are nozzle 19A and 37 of the MARIN series.[3] These have a rounded trailing edge to ease fabrication and increase efficiency sailing astern. Initially, the propellers of the Wageningen B-series were used, later the Kaplan-type with a wider blade tip.

Physics

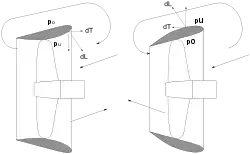

| |

|

dT = Thrust |

pu: Negative pressure |

In a Kort nozzle, the inflow velocity is increased, reducing pressure. This lowers thrust and torque of the propeller. At the same time, a circulation occurs, resulting in an inward aimed force, that has a forward component. The duct therefore has a positive thrust. This is normally larger than the thrust reduction of the propeller. The small clearance between the propeller and duct reduces tip vortex, increasing efficiency.

As drag increases with increasing speed, eventually this will become larger than the added thrust. Vessels that normally operate above this speed are therefore normally not fitted with ducts. When towing, tugboats sail with low speed and heavily loaded propellers, and are often fitted with ducts. Bollard pull can increase up to 30% with ducts.

With decelerating ducts, the circulation opposite of the Kort nozzle, resulting in a negative thrust of the duct. This type is used for high speed vessels with increased exposure to cavitation and vessels that want to reduce noise levels, such as warships.

See also

- Azipod – Electric drive azimuth thruster

- Axial fan design

- Kitchen rudder – Type of directional propulsion system for vessels

- Pleuger rudder – A thruster assisted ship's rudder

References

Bibliography

- Carlton, J. (2007): Marine Propellers and Propulsion, Butterworth-Heinemann

- Ghose, J.P., Gokarn R.P. (2004): Basic Ship Propulsion, Allied Publishers

- Oosterveld, M.W.C. (1970): Wake Adapted Ducted Propellers, Nederlands Schip Model Basin, Wageningen