Haskell Manufacturing Company

The Haskell Manufacturing Company was a manufacturing company. It was located on Rowe Street about a mile north of downtown Ludington, Michigan. Their main product was haskelite, a plywood made from a waterproof glue developed by Henry L. Haskell in the early 1900s. The plywood was veneer wood panels of different thicknesses and was used to make novelty items, furniture, and paneling for construction. The thinner plywood was molded into shapes for body parts of airplanes and transportation vehicles. It was manufactured with different styles and types to fit particular needs.

| |

| Industry | Manufacturing |

|---|---|

| Fate | Sold off part by part |

| Founded | 1911 |

| Defunct | 1956 |

| Headquarters | Ludington, Michigan |

| Products | plywood |

| Revenue | $5,000,000 in 1922[1] |

| Subsidiaries | |

Haskell Manufacturing Company Building | |

| |

| Location | 801 North Rowe St., Ludington, Michigan |

| Coordinates | 43°57′54″N 86°26′43″W |

| Built | 1892 |

| NRHP reference No. | 1100005785[2] |

| Added to NRHP | November 10, 2020 |

The company made airplane body parts for military aircraft used in World War I. The manufacturing firm had several subsidiary companies, factories, and offices that were related and supported them. The company was eventually sold off in parts in the mid-20th century. The building where the company was located in Ludington has since been converted to affordable housing.

History

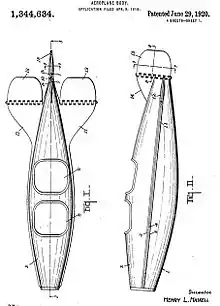

Henry L. Haskell devised a way to make waterproof glue in 1913 from a derivative of dried cow blood. He used this adhesive to put together cross-grained thin veneer layers of wood to create a product referred to as a flat sheet "panel" – now known as plywood ("plies" of wood). The plywood was named Haskelite after himself. In 1915, he innovated a method to mold this plywood into three-dimensional shapes using heat, hydraulic pressure and his patented waterproof glue.[4]

Haskell created the Haskell Manufacturing Company in 1916 in Ludington, Michigan.[5] The Haskelite plywood was first manufactured there.[6] The thinner three-layered plywood pieces could be molded into any shape desired. It was used for various vehicles including airplanes and flying boats. The plywood constructed canoes, boats, trucks, buses, automobiles, and airplanes.[7] The first plane made with moldable plywood was constructed with Haskelite.[7] It was the Curtiss two-place fighter Whistling Bill.[8] Sea sleds and hydro-airplane pontoons were made of haskelite. The "panels" came in dimensions up to 7.5 by 50 feet (2.3 by 15.2 m) in length. The thickness varied by the number of layers requested. Other uses for the plywood were door panels, roofing, flooring, portable houses, bread boxes, grain chutes, drain boards, toboggans, barrels, shipping containers, refrigerators, and canoes.[4]

Haskell in 1917 sold his controlling interest to Bonbright and Company, a group of investment bankers from Detroit and New York City. The company then employed one hundred and eighty men and made ten thousand square feet of plywood per day.[9] They changed the main focus of the company at the beginning of World War I to build military airplane body parts.[10] The Ludington-based plant erected a million dollar expansion to its facilities and increased its employment considerably.[11]

The company in 1918 opened its second plant in Grand Rapids, Michigan. This factory was called the Haskelite Manufacturing Corporation. Its main purpose was to supply plywood for the United States and its allies for the construction of military vehicles and aircraft. This factory was twice the size as the original Ludington plant. It employed a thousand men and produced one hundred thousand square feet of plywood per day.[9] Between the two factories, there were millions of feet of plywood produced during World War I. The manufacturing plant in Ludington was part of the larger Haskelite Manufacturing Corporation that was headquartered in Chicago.[1]

After the war military aircraft were no longer needed and so this use was discontinued and other uses were found for the plywood. One item the firm built was wooden boats because of the waterproof characteristics of the plywood. Its main product was the Haskell canoe, which was molded from one piece of 3/16th's inch plywood.[12]

In the Grand Rapids factory, "Plymetl" was made as one of several specialty plywood products. It was a wooden plywood faced on one side or both with metal (steel or aluminum). One use for this metal-plywood material was for climate controlled facilities (i.e. fur storage, food storage).[13] Another use was for public restroom facilities.[14] One more type of plywood that the company made was "Phemoloid". This finished plywood planking was used in houses, commercial facilities, railroad cars, trucks, airplanes, and luxury automobiles.[15]

The Grand Rapids factory plant made a deal in 1939 with Fairchild Engine and Airplane Corporation and the industrialist Howard Hughes to manufacture low-priced airplanes. The manufacturing companies used a special process of heat and pressure to fuse together wood fibers and synthetic resins to make a plywood product for the construction of planes. It was the state-of-the-art in making airplanes and more economical than the currently used method of plane construction. The Haskell company and Fairchild had already developed techniques of molding fuselages and aircraft wings to put together airplanes.[16]

Haskell Manufacturing Company had many subsidiaries. One was Marquette Veneer, which made birch Haskelite doors; another company associated was Gillett Log, a Wisconsin company subsidiary that produced the birch wood for door panels.[17] Due to competition the spin-off plant of Haskelite Manufacturing Corporation in Grand Rapids was sold to an industrial buyer in 1949.[18] The Haskell Company agreed to sell its other assets to Evans Products Company of Plymouth, Michigan at the end of 1956.[19]

Haskell building

Haskell established the Haskell Manufacturing Company in the building at 801 N. Rowe Street. This building was originally erected by the Mendelson Manufacturing Company in 1892 for making pants. This company was there for two years and went out of business. The building was vacant for nearly a decade and was owned by Antoine E. Cartier. The Tubbs Manufacturing Company occupied the building from 1904 to 1911. The company expanded the size of the structure considerably to accommodate their furniture making business. Haskell's Carrom Company had then moved into this building in 1911 to make the carroms game.[20]

The Haskelite building, as the locals refer to it, was occupied by several different businesses after 1934. One of these was the Civilian Conservation Corps. The Wolverine Sportswear Company occupied the building from 1944.[21] Going into the 21st century it has been occupied by the local business Change Parts. These owners donated the building in 2019 for conversion to affordable housing.[22]

Haskell building, SE

Haskell building, SE Haskell building, East

Haskell building, East Haskell building, SW

Haskell building, SW Haskell building, North

Haskell building, North

References

- "Ludington Man Starts Factories that pay more than $5,000,000 in Wages". Mason County Enterprise. Ludington, Michigan. May 9, 1922. p. 1.

- "National Register of Historic Places Program: Weekly List of Actions Taken on Properties: 11/6/2020 Through 11/13/2020". National Park Service. Retrieved November 13, 2020.

- US Government. "US 1344634A". US Patent Office. Retrieved May 1, 2020.

- Factory Management 1918, p. 1036.

- Dunbar 1955, p. 439.

- Cabot, James L. (June 26, 1993). "Local Company Contributed to war effort". Daily News. Ludington, Michigan – via Newspapers.com

.

. - Cabot 2005, p. 114.

- Kane, p. 70.

- "Mammouth Industry locates in Grand Rapids". Grand Rapids Progress, Vol 7, No. 1. Grand Rapids, Michigan: Grand Rapids Association of Commerce. 1918. Retrieved May 1, 2020.

- Furniture Manufacturer 1917, p. 204.

- "Michigan Meanderings". The Lumber Trade Journal, Volume 72.

- "Ludington Pleased with Haskell Canoe Manufacturing Co". Daily News. Ludington, Michigan. May 27, 1917 – via Newspapers.com

.

. - "Troy Laundry's New Large Scientific Fur Storage Vault". The Evening News. Harrisburg, Pennsylvania. May 3, 1940 – via Newspapers.com

.

. - Railway_Age 1948, p. 47.

- Clute 1940, p. 278.

- "Low-Cost Plane to be Produced". Battle Creek Enquirer. Battle Creek, Michigan. August 4, 1939 – via Newspapers.com

.

. - "Marquette Gets A Veneer Plant". Ironwood Daily Globe. Ironwood, Michigan. July 18, 1951 – via Newspapers.com

.

. - "Haskelite Co. To Sell Unit / Will Dispose of Plant". Grand Rapids Press. Grand Rapids, Michigan. April 2, 1949 – via Newspapers.com

.

. - "Evans Company Adds to Plant Holdings". Corvallis Gazette-Times. Corvallis, Oregon. December 28, 1956 – via Newspapers.com

.

. - Williams, Leonard P. (December 22, 1952). "Carrom Industries / from Lumber to Game Boards". Daily News. Ludington, Michigan – via Newspapers.com

.

. The story is told that, back in the last quarter of the 19th Century, when Mr. Haskell was teaching a Sunday school class of boys in one of the local churches, he viewed with alarm the tendency of small boys to loaf around the pool halls of that day. His game of carroms is supposed to have been developed and produced to help provide wholesome entertainment for young people in their homes and away from places where they might come under questionable influences.

- MMFR 1944, p. 121.

- Moore, Lynn. "Donated century-old building could become Ludington apartments". MLive Media Group. Retrieved April 22, 2020.

Sources

- Cabot, James L. (2005). Ludington: 1830–1930. Arcadia Publishing. ISBN 978-0-7385-3951-5.

Whistling Bill, the first plane made with this material, was a Curtiss biplane built in 1918.

- Clute, Eugene (1940). Progressive Architecture. Reinhold Publishing Corporation.

- Dunbar, Willis Frederick (1955). Michigan Through the Centuries. Lewis Historical Publishing Company.

- Factory Management (1918). Factory: The Magazine of Management. A.W. Shaw co.

- Furniture Manufacturer (1917). Furniture Manufacturer and Artisan. Grand Rapids Furniture Record Company.

- Kane, Joseph Nathan. Famous First Facts and Records.

The first airplane of molded plywood was the "Whistling Bill," a two-place fighter, built in 1918 by the Curtiss Aeroplane and Motor Company, Garden City, Long Island, N.Y. The fuselage was made of four 3/32nd-inch longitudinal sheets of Haskelite, three-ply birch plywood, steamed and formed to contour in a concrete die.

- MMFR (July 1944). Michigan Manufacturer and Financial Record. Pick Publications.

- Railway_Age (1948). Railway Age. Simmons-Boardman Publishing Company.