Hydrocyclone

A hydrocyclone (often referred to by the shortened form hydroclone or cyclone) is a device to classify, separate or sort particles in a liquid suspension based on the ratio of their centripetal force to fluid resistance. This ratio is high for dense (where separation by density is required) and coarse (where separation by size is required) particles, and low for light and fine particles. Hydrocyclones also find application in the separation of liquids of different densities.

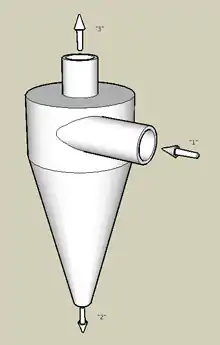

- the liquid-solid mixture enters,

- heavy solids leave,

- cleaned liquid leaves.

A different description: A hydrocyclone is a mechanical device designed to reduce or increase the concentration of a dispersed phase, solid, liquid or gas of different density, by means of centripetal forces or centrifugal forces within a vortex.[1]

The mixture is injected into the hydrocyclone in such a way as to create the vortex and, depending upon the relative densities of the two phases, the centrifugal acceleration will cause the dispersed phase to move away from or towards the central core of the vortex.

A hydrocyclone will normally have a cylindrical section at the top where liquid is being fed tangentially, and a conical base. The angle, and hence length of the conical section, plays a role in determining operating characteristics.

Design

A hydrocyclone is a classifier that has two exits on the axis: one on the bottom (underflow or reject) and one at the top (overflow or accept). The underflow is generally the denser or coarser fraction, while the overflow is the lighter or finer fraction. It has no moving parts and its operation depends on two major parameters:

- The characteristics of the feed stream.

- The geometry of the cyclone.

The characteristics of the feed stream include size distribution of solids in the feed stream, pulp density (percent solids in the slurry), pulp viscosity and the inlet pressure for solid/liquid separation. In liquid/liquid feed streams, for example in oily water, the main feed characteristics are based on oil droplet size and distribution, oil density, water density, oil concentration, viscosity and temperature.

The geometry of the cyclone involves-inlet shape and area, cyclone dimensions (cone angle, length of cylindrical section and total length of the cyclone) and inlet, vortex and apex diameters.

Internally, inertia is countered by the resistance of the liquid, with the effect that larger or denser particles are transported to the wall for eventual exit at the underflow side with a limited amount of liquid, while the finer, or less dense particles, remain in the liquid and exit at the overflow side through a tube extending slightly into the body of the cyclone at the center.[2]

Forward hydrocyclones remove particles that are denser than the surrounding fluid, while reverse hydrocyclones remove particles that are less dense than the surrounding fluid. In a reverse hydrocyclone the overflow is at the apex and the underflow at the base. There are also parallel-flow hydrocyclones where both the accept and reject are removed at the apex. Parallel-flow hydrocyclones remove particles that are lighter than the surrounding fluid.[3]

Hydrocyclones can be made of metal (mostly steel), ceramic or plastic (such as polyurethane, polypropylene, or other types). Metal or ceramic hydrocyclones are used for situations requiring more strength, or durability in terms of heat or pressure. When there is an occurrence of much abrasion (such as occurs with sand particles) polyurethane performs better than metals or ceramics. Metal lined with polyurethane is used in cases of combined abrasion and high pressure.

In a suspension of particles with the same density, a relatively sharp cut can be made. The size at which the particles separate is a function of cyclone diameter, exit dimensions, feed pressure and the relative characteristics of the particles and the liquid. Efficiency of separation is a function of the solids' concentration: the higher the concentration, the lower the efficiency of separation. There is also a significant difference in suspension density between the base exit (fines) and the apex exit, where there is little liquid flow.

If the size range of the particles is limited, but there are differences in density between types of particles, the denser particles will exit preferentially at the apex. The device is therefore a means of selective concentration of, for example, minerals.

This device is also related to the centrifuge; both of them are intended to separate heavies and lights in liquid by application of centrifugal force.[4] Centrifuges generate the separation force by rotation of the entire equipment; hydrocyclones utilise centrifugal forces from the movement of the fluids to achieve separation.

Design equations

For a Bradley hydrocyclone, the dimensions of each part are always in the same proportions. The pressure drop should be between 20 psi and 60 psi.

- Di is the inlet diameter

- Do is the overflow diameter

- Du is the underflow diameter

- Dc is the chamber diameter

- L is the height of the hydrocyclone

- l is the height of the cylinder part of hydrocyclone

- ℓ is the height of the vortex tube of hydrocyclone

- Le is the length of the outlet tube

- Theta is the angle at the base of the hydrocyclone

- Di/Dc = 1/90

- Do/Dc = 1/5

- Du/Dc = -

- L/Dc = -

- l/Dc = 1/2

- ℓ/Dc = 1/3

- Theta = 9 degrees

Uses

A hydrocyclone is most often used to separate "heavies" from a liquid mixture originating at a centrifugal pump or some other continuous source of pressurized liquid, or two-phase (gas-liquid) systems.[5] A hydrocyclone is most likely to be the right choice for processes where "lights" are the greater part of the mixture and where the "heavies" settle fairly easily.

Generally, hydrocyclones are used in continuous flow systems so that the instantaneous liquid inflow to the hydrocyclone is equal to the total instantaneous outflow of "lights" plus "heavies". In cases where "heavies" are a very small part of the whole liquid, it is sometimes advantageous to accumulate them in the bottom of the hydrocyclone for batchwise removal.

Applications include:

- In the potato, cassava, wheat and corn starch industry for both concentration and washing of the crude starch milk. Hydrocyclone replace separators as a more price efficient separation technique.

- In pulp and paper mills to remove sand, staples, plastic particles and other contaminants.

- In the drilling industry to separate sand from the expensive clay that is used for lubrication during the drilling.

- In oil industry to separate oil from water or vice versa.

- In metal working to separate metal particles from cooling liquid.

- In French fries and potato chips plants for in-line starch recovery from cutting water and from waste water.

- In mineral processing, hydrocyclones are used extensively both to classify particles for recirculation in grinding circuits and to differentiate between the economic mineral and gangue.

- To remove sand and silt particles from irrigation water for drip irrigation purposes.

See also

- Cyclonic separation

- List of waste-water treatment technologies

- Sand separator

- Desander

References

- The Hydrocyclone: Dr Derek Alan Colman, Department of Mechanical Engineering, University of Southampton, England

- Hydrocyclone behaviour

- Separation principle Archived June 10, 2007, at the Wayback Machine

- "Rotational particle separator: an efficient method to separate micron-sized droplets and particles from fluids" (PDF). Archived from the original (PDF) on 2015-02-22. Retrieved 2013-08-15.

- Colli, A. N.; Fornés, J. P.; González Pérez, O.; Bisang, J. M. (June 2019). "Evaluation of a modified hydrocyclone as electrochemical reactor for processing of two-phase (gas-liquid) systems". Electrochimica Acta. 309: 219–227. doi:10.1016/j.electacta.2019.04.056.