Hydroxyl-terminated polybutadiene

Hydroxyl-terminated polybutadiene (HTPB) is an oligomer of butadiene terminated at each end with a hydroxyl functional group. It reacts with isocyanates to form polyurethane polymers.

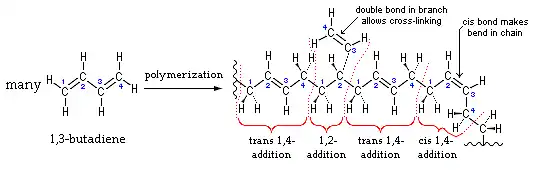

HTPB is a translucent liquid with a color similar to wax paper and a viscosity similar to corn syrup. The properties vary because HTPB is a mixture rather than a pure compound, and it is manufactured to meet customers' specific requirements. A typical HTPB is R-45HTLO.[1] This product consists of oligomeric units typically containing 40–50 butadiene molecules bonded together, with each end of the chain terminated with a hydroxyl [OH] group:

R-45HTLO has a functionality of 2.4-2.6, which means that there is (approximately) one additional hydroxyl group located along the chain for every two oligomeric units. This provides side-to-side linkage for a stronger cured product. HTPB is usually cured by an addition reaction with di- or poly-isocyanate compounds.

Uses

Polyurethanes prepared from HTPB can be engineered for specific physical properties; polyurethanes may be highly elastic or tough and rigid. Some products include: rigid foam insulation panels; durable elastomeric wheels and tires (used for roller coasters, escalators, skateboards, etc.); automotive suspension bushings; electrical potting compounds; high-performance adhesives; surface coatings and surface sealants; synthetic fibers (e.g., Spandex); carpet underlay; hard-plastic parts (e.g., for electronic instruments).

An important application of HTPB is in solid rocket propellant. It binds the oxidizing agent, fuel and other ingredients into a solid but elastic mass in most composite propellant systems. The cured polyurethane acts as a fuel in such mixtures. For example, HTPB is used in all 3/4 stages of the Japanese M-5 rocket satellite launchers and PSLV rocket developed by ISRO for satellite launches. JAXA describes the propellant as "HTPB/AP/Al=12/68/20", which means, proportioned by mass, HTPB plus curative 12% (binder and fuel), ammonium perchlorate 68% (oxidizer), and aluminum powder 20% (fuel).

Similar propellants, often referred to as APCP (ammonium perchlorate composite propellant) are used in larger model rockets. A typical APCP produces 2–3 times the specific impulse of the black powder propellant used in most smaller rocket motors.

HTPB is also used as a hybrid rocket fuel.[2] With N2O (nitrous oxide, or "laughing gas") as the oxidizer, it is used to power the SpaceShipTwo hybrid rocket motor developed by SpaceDev.[3] It will also be oxidized by high-test peroxide in the land speed record attempt Bloodhound SSC.

References

- http://www.crayvalley.com/docs/TDS/poly-bd-r-45htlo.pdf

- G. P. Sutton and Oscar Biblar, Rocket Propulsion Elements, (Eighth edition), pp. 595–599, John Wiley and Sons 2010.

- "SpaceDev Hybrid Propulsion". SpaceDev. Archived from the original on 2007-11-05. Retrieved 2008-07-24.

External links

| Wikimedia Commons has media related to Hydroxyl-terminated polybutadiene. |

- US Patent 5159123 description of synthesis and other details.