Pintle

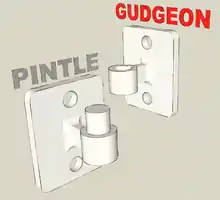

A pintle is a pin or bolt, usually inserted into a gudgeon, which is used as part of a pivot or hinge. Other applications include pintle and lunette ring for towing, and pintle pins securing casters in furniture.

Use

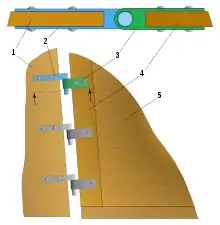

Pintle/gudgeon sets have many applications, for example: in sailing to hold the rudder onto the boat; in transportation a pincer-type device clamps through a lunette ring on the tongue of a trailer; in controllable solid rocket motors a plug moves into and out of the motor throat to control thrust.

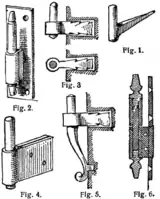

In electrical cubicle manufacture, a pintle hinge is a hinge with fixed and moving parts. The hinge has a pin "pintle" and can be both external and internal. The most common type consists of three parts. One part on the body of the cubicle, one part on the door and the third part is the pintle.

In transportation, a pintle hitch is a type of tow hitch that uses a tow ring configuration to secure to a hook or a ball combination for the purpose of towing an unpowered vehicle.[1][2]

As a weapon mount, a pintle mount is used with machine guns as the mounting hardware that mates the machine gun to a vehicle or tripod. Essentially, the pintle is a bracket with a cylindrical bottom and a cradle for the gun on top; the cylindrical bottom fits into a hole in the tripod while the cradle holds the gun.

In furniture, a pintle is usually fitted to a caster; the pintle is then inserted into a base, fixing the caster to that base.

In rocketry, a pintle injector uses a single-feed fuel injector rather than the hundreds of smaller holes used in a typical rocket engine.[3] This simplifies the engine, reducing cost and improving reliability, while surrendering some performance. Grumman used the pintle-based Rocketdyne RS-18 for the Ascent stage of the Apollo Lunar Module. TRW used this same injector for the Descent Propulsion System on Apollo's Lunar Module. Notable modern uses are in the Merlin engines developed by SpaceX.

Pintle is also a common term used in the design of aircraft landing gears. It describes the attachment point between the landing gear structure and the aircraft structure. The pintle is the bolt around which the landing gear rotates when it is extended/retracted into/out of the aircraft. The pintle is a highly stressed component during landing manoeuvres and is often made from exotic metal alloys.[4] For World War II aircraft with sideways-retracting main gear units, carefully set-up "pintle angles" for such axes of rotation during retraction and extension allowed the maingear struts to be raked forward while fully extended for touchdown and better ground handling, while permitting retraction into rearwards-angled landing gear wells in their wings to usually clear the forward wing spar for stowing while in flight.[5]

Gallery

Image depiciting a gudgeon with a pintle

Image depiciting a gudgeon with a pintle Pintle hinge parts

Pintle hinge parts Pintle Hinge installed on a switchboard

Pintle Hinge installed on a switchboard Swivel caster with pintle

Swivel caster with pintle Pintle hook

Pintle hook Lunette ring, used with a pintle in heavy towing applications

Lunette ring, used with a pintle in heavy towing applications

References

- "Pintle Hooks and Combination Hitches", accessed 2011-02-04.

- "Pintle Hitch, Hooks, Mounts" Archived 2013-01-19 at the Wayback Machine, accessed 2013-01-22

- "Pintle Injector Rocket Engines", accessed 2011-02-04.

- Norman S. Currey (1988). Aircraft Landing Gear Design: Principles and Practices. ISBN 978-1-60086-018-8.

- Snyder, Chuck (August 2012). "How to Install Retractable Landing Gear". Model Aviation, p. 37.