Rotary printing press

A rotary printing press is a printing press in which the images to be printed are curved around a cylinder. Printing can be done on various substrates, including paper, cardboard, and plastic. Substrates can be sheet feed or unwound on a continuous roll through the press to be printed and further modified if required (e.g. die cut, overprint varnished, embossed). Printing presses that use continuous rolls are sometimes referred to as "web presses".

| Part of a series on the | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

| History of printing | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||

Developmental history

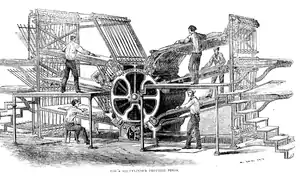

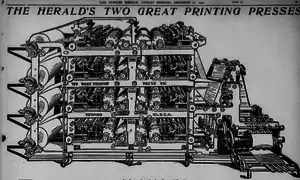

William Nicholson filed a 1790 patent for a rotary press. The rotary press itself is an evolution of the cylinder press, also patented by William Nicholson, invented by Beaucher of France in the 1780s and by Friedrich Koenig in the early 19th century.[1][2] Rotary drum printing was invented by Richard March Hoe in 1843. An 1844 patent replaced the reciprocating platforms used in earlier designs with a fixed platform served by rotating drums, and through a series of advances a complete rotary printing press was perfected in 1846,[3] and patented in 1847. It appeared in Edinburgh in 1851 and then traveled to London where it was used by the Times newspaper in 1853, where it then traveled to France in 1866 and Germany in 1873. By the time it reached Spain in 1885 it had become common use.[4] Some sources describe the Parisian Hippolyte Auguste Marinoni as the inventor of the Rotary printing press, but this was the subject of a patent dispute that was decided in Hoe's favor. A.S. Abell of the Baltimore Sun was the first American user of the rotary press.[5]

Types of rotary printing presses

Today, there are three main types of rotary presses; offset (including web offset), rotogravure, and flexo (short for flexography). Although the three types use cylinders to print, they vary in their method.

In Offset lithography, the image is chemically applied to a plate, generally through exposure of photosensitive layers on the plate material. Lithography is based on the fact that water and oil do not mix, which enables the planographic process to work. In the context of a printing plate, a wettable surface (the non-image area) may also be termed hydrophilic and a non-wettable surface (the image area) hydrophobic.

Gravure is a process in which small cells or holes are etched into a copper cylinder, which are able to be filled with ink. All the colours are etched in different angles, thus while printing every colour is placed in proper position to give the appropriate image.

Flexography is a relief system in which a raised image is created on a typically polymer-based plate.

In stamp collecting, rotary-press-printed stamps are sometimes a different size than stamps printed with a flat plate. This happens because the stamp images are farther apart on a rotary press, which makes the individual stamps larger (typically 0.5 to 1 mm (0.020 to 0.039 in)).

See also

References

| Wikimedia Commons has media related to Rotary printing presses. |

- http://www.edwardlloyd.org/printing.htm

- Weygand, Zina (2009-08-07). The Blind in French Society from the Middle Ages to the Century of Louis Braille. ISBN 9780804772389.

- Meggs, Philip B. (1998). A History of Graphic Design (Third ed.). John Wiley & Sons, Inc. p. 147. ISBN 978-0-471-29198-5.

- Lyons, M. (2013). Books: a living history. London: Thames & Hudson.

- Hoiberg, Dale H., ed. (2010). "Abell, A(runah) S(hepardson)". Encyclopædia Britannica. I: A-ak Bayes (15th ed.). Chicago, Illinois: Encyclopædia Britannica Inc. pp. 26. ISBN 978-1-59339-837-8.