Williams Olefins Plant explosion

The Williams Olefins Plant explosion occurred on June 13, 2013 at a petrochemical plant located in Geismar, an unincorporated and largely industrial area 20 miles (32 km) southeast of Baton Rouge, Louisiana.[1][2][3] Two workers were killed and 114 injured.[4][5] The U.S. Occupational Safety and Health Administration (OSHA) and the U.S. Chemical Safety and Hazard Investigation Board (CSB) launched investigations to determine how and why the heat exchanger failed.[4][6] The Chemical Safety Board concluded that a standby heat exchanger had filled with hydrocarbon. This heat exchanger was isolated from its pressure relief; shortly after the heat exchanger was heated with hot water, the hydrocarbon flashed to vapor, ruptured the heat exchanger, and exploded.[1]

Post-blast photograph of the heat exchanger which ruptured catastrophically, causing extensive explosion and fire damage to the plant. | |

| Date | June 13, 2013 |

|---|---|

| Time | 8.37 am CDT (UTC−05:00) |

| Location | William Olefins Inc., 5205 LA 3115, Geismar, Louisiana. |

| Coordinates | 30.234238°N 91.052937°W |

| Deaths | 2 |

| Non-fatal injuries | 114 |

Location of the Williams Olefins Plant in Louisiana. | |

The effects of the explosion were felt several miles away. Senator Troy Brown [D-Napoleonville], who was at his home five miles from the plant when the blast occurred, said, "For about a good two to three seconds, it felt like an earthquake."[7] A shelter-in-place order was issued to residences and businesses within a two-mile (3.2 km) radius of the plant.[8][9]

Background

The Williams Olefins Plant was established in 1968 by Allied Chemical and transferred to Williams Olefins following a merger with Union Texas Petroleum in September 1999.[10]

The plant produces ethylene, propylene and other products through steam cracking of ethane and propane.[10][11] This process uses high temperatures to break long-chain hydrocarbons into shorter-chain olefins.[12] The ethane is diluted with steam and briefly heated in a furnace without the presence of oxygen. Typical reaction temperatures are very high, at around 1,560 °F (850 °C), but the reaction is only allowed to take place very briefly. After the cracking temperature has been reached, the gas is quickly quenched in the heat exchanger to stop the reaction. The plant produces 40,000 tons (36,000 tonnes) of propylene and 650,000 tons (590,000 tonnes) of ethylene every year for use in the plastics industry.[13]

The explosion was the first major incident in the plant's history, although there had been numerous leaks of flammable gases in recent years.[10] On December 18, 2012 workers discovered "a visible leak" of propylene gas. According to a report submitted by Williams Olefins to the Louisiana Department of Environmental Quality (DEQ), 514 pounds (233 kg) of propylene gas escaped. Williams Olefins said, "Piping corrosion under insulation is believed to be a significant factor in this incident [...] This was a small isolated corrosion location that had not been previously found."[14] The Times-Picayune of New Orleans reported that there had been leaks of 100 pounds (45 kg) each of ethylene and volatile organic compounds in 2010, 93 pounds (42 kg) of benzene in 2009, and 4,000 pounds (1,800 kg) of propylene in 2008.[14]

Event

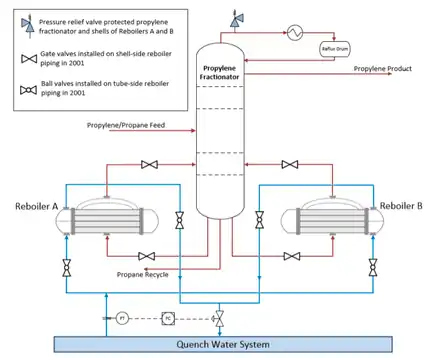

The event was investigated by the Chemical Safety Board, and their report pieced together the event.[1] At the Williams Geismar Olefin Plant, propylene was extracted from a stream of hydrocarbon by heating the mixture in one of two reboilers, followed by fractional distillation. The reboilers were of a shell and tube design, with the hydrocarbon stream in the shell side, and hot water in the tubes.

While the reboilers were originally designed to be used concurrently, a modification was performed in 2001 to allow each reboiler to be used independently from the other, allowing a fouled reboiler to be cleaned without shutting the unit down. Valves were installed to isolate each reboiler from the other, and they had the effect of preventing the isolated reboiler from accessing the pressure relief valve at the top of the propylene distillation column.

Reboiler B, that ultimately failed, had been purged with nitrogen and isolated from process with a single closed block valve after maintenance activity in February 2012. Some amount of liquid propane was determined to have entered Reboiler B despite this closed block valve. On June 13, 2013, Reboiler A that was in operation was believed to be fouled, and the operations supervisor intended to start the process (engaging operations and maintenance personnel) to switch to Reboiler B. According to process logs, hot water started flowing into Reboiler B at 8:33 am, and the reboiler exploded 3 minutes later after the hydrocarbon process fluid flashed to vapor, ruptured the shell of the heat exchanger, and ignited.

The explosion killed an operator at the scene, and the operations supervisor died from burns the next day. 167 other people on-site were injured as well. 30,000 lb. of hydrocarbons was released, and the fire lasted for 3.5 hours.

Investigations

Internal investigation

On October 3, 2013 Williams Olefins announced the results of their internal investigation. The company said that a rupture in the heat exchanger caused a vapor cloud "which was ignited by an unknown source, causing the explosion."[15]

OSHA investigation

On December 11, 2013 OSHA cited Williams Olefins for six process safety management standard violations, including one willful, and fined the company $99,000.[16] Dorinda Folse, OSHA's Baton Rouge area director, said: "Williams Olefins violated safety and health standards which, when followed, can protect workers from hazardous chemicals. It is the employer's responsibility to find and fix workplace safety violations and to ensure the safety of its workers. Failing to do so cost two workers their lives."[17] The five serious violations, where there was "substantial probability that death or serious physical harm could result from a hazard about which the employer knew or should have known", were:

- inadvertently mixing hot quench water with propylene

- failing to provide appropriate pressure protection for a pressure vessel

- failing to complete a process hazard analysis to address the opening of hot quench water flow into a pressure vessel

- failing to properly document workplace training

- failing to promptly correct deficiencies related to process safety management discovered by an internal compliance audit team

The willful violation—defined as one "committed with intentional, knowing or voluntary disregard for the law's requirements, or with plain indifference to worker safety and health"—was the company's failure to develop clear, written procedures for how to change and put idle pressure vessels into service.[17]

Chemical Safety Board investigation

The Chemical Safety Board issued a detailed report,[1] and some of the key lessons include:

- Overpressure protection is critical to protect pressure vessels from rupture.

- Valves can leak or be operated inadvertently, as opposed to pipe blinds.

- The importance of a robust safety culture, and the use of tools such as process hazard analyses (PHAs), management of change reviews (MOCs), and pre-startup safety reviews (PSSRs) at identifying potential hazards, evaluating their potential effects, effectively addressing them, followed by verification.

Lawsuits

In the first civil trial regarding the explosion, four workers filed suit against Williams Olefins LLC and parent company Williams Companies, Inc. for their alleged negligence.[18]

See also

References

- "Williams Olefins Plant Explosion and Fire". U.S. Chemical Safety and Hazard Investigation Board. October 19, 2016. Retrieved August 30, 2020.

- "Williams Companies Inc. olefins plant explosion". Houston Chronicle. Houston. June 14, 2013. Retrieved July 20, 2013.

- DeLuca, Matthew (June 13, 2013). "One dead, scores injured in Louisiana chemical plant explosion". NBC News. New York City. Retrieved July 20, 2013.

- Mitchell, David J. (July 10, 2013). "Metallurgical testing key in Geismar plant explosion". The Advocate. Baton Rouge. Retrieved July 20, 2013.

- Schleifstein, Mark (June 26, 2013). "Geismar explosion and fire released more than 31,000 pounds of toxic chemicals, company reports". The Times-Picayune. New Orleans. Retrieved July 20, 2013.

- Wallace, Ben (June 16, 2013). "Agencies look into plant blast". The Advocate. Baton Rouge. Retrieved July 20, 2013.

- Mitchell, David J.; Jones, Terry L.; Ward, Steven; Denstorff, Darlene; Couvillion, Vic; Wallace, Ben; Wold, Amy; Mustian, Jim (June 25, 2013). "Hammond man killed in plant explosion". The Advocate. Baton Rouge. Retrieved July 20, 2013.

- Valencia, Nick; Sayers, Devon (June 14, 2013). "2nd man dies after Louisiana chemical plant explosion". The Dallas Weekly. Dallas. Retrieved July 20, 2013.

- Smith, Sandy (June 13, 2013). "Explosion Rocks Louisiana Chemical Plant, One Fatality Reported, Many Injured". EHS Today. Cleveland. Retrieved July 21, 2013.

- Wold, Amy (June 14, 2013). "Williams Olefins had humble beginnings". The Advocate. Baton Rouge. Retrieved July 20, 2013.

- "Texas company wins $300 million contract for Geismar project". The Advocate. Baton Rouge. April 9, 2012. Retrieved July 20, 2013.

- Freudenrich, Craig (October 2011). "How Oil Refining Works". HowStuffWorks. Retrieved July 20, 2013.

- DuBose, Ben (June 13, 2013). "Explosion hits Williams Louisiana olefins plant". Hydrocarbon Processing. Houston. Retrieved July 20, 2013.

- McGaughy, Lauren (June 14, 2013). "Geismar plant had history of noncompliance, leaks before fatal explosion". The Times-Picayune. New Orleans. Retrieved July 20, 2013.

- Samuels, Diana (October 3, 2013). "Geismar plant explosion caused by rupture, unknown ignition source, company says". The Times-Picayune. New Orleans. Retrieved July 17, 2014.

- Lane, Emily (December 11, 2013). "Williams Olefins fined $99,000 by OSHA for Geismar plant explosion". The Times-Picayune. New Orleans. Retrieved July 17, 2014.

- "US Labor Department's OSHA cites Williams Olefins in Geismar, La., for 6 safety violations after an explosion killed 2 workers and injured 80 people". Occupational Safety and Health Administration. December 11, 2013. Retrieved July 17, 2014.

- Jones, Terry (September 7, 2016). "Plaintiffs claim executives willfully ignored problems that led to deadly 2013 blast at Williams Olefins plant in Geismar". The Advocate. Plaquemine. Retrieved October 5, 2016.