Circuit integrity

Circuit integrity refers to the operability of electrical circuits during a fire. It is a form of fire-resistance rating. Circuit integrity is achieved via passive fire protection means, which are subject to stringent listing and approval use and compliance.

Fireproofing

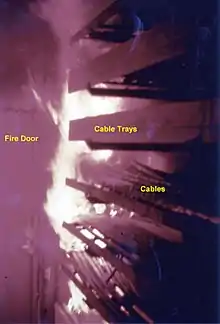

Providing fireproofing for cables, cable trays, or electrical conduit, is meant to keep cables operational during a specified fire exposure and time. This can be done in two different ways:

- Cable coating is generally considered a fire retardant, which lowers the spread of flame and generation of smoke along the combustible cable jacketing. Some cable coating systems are able to achieve a measure of circuit integrity, which is demonstrated and quantified through certification listing and listing and approval use and compliance.

- An enclosure for the complete cable tray/ ladder can be provided.

- In all cases, the installed configuration must meet the certification and listing of the tested system. Alternatively, cables that achieve fire-resistance ratings on their own can be used, such as mineral-insulated copper-clad cable, or MI cable. Mica insulated cables have also demonstrated a measure of circuit integrity for small cables.

- For petrochemical industry cable tray wrap enclosures are more suitable as the failure temperature of the cables are very low about 121 °C and more over cable tray can lose structural stability and integrity as the nature of fire is hydrocarbon 1093 °C.

Testing and certification

For Civil Building Industry, In Canada, testing is run in accordance with ULC-S101, as required by the local building code. Unfortunately, S101 is ill equipped to deal realistically with circuit integrity, particularly for enclosures. For circuit integrity cables, one simply uses a full scale wall panel test, loops the cables through the fire, energises the cables and quantifies the current carrying capacity of the cables during the fire.

There are two ways of achieving circuit integrity. One may either choose mineral insulated or otherwise fire-resistant (tested for that purpose) cables, or one may use an enclosure that was tested for that purpose. This is where "grandfathered" systems still find acceptance in certain parts in North America. A prime example of this is Canada, where the code indicates that 2" of concrete coverage over or around electrical circuits is sufficient to obtain an unquantified duration of circuit integrity. No testing documentation exists to qualify this measure, according to the Institute for Research in Construction, a part of the National Research Council of Canada. 2" of concrete, regardless of the conductor configuration, percentage fill, etc. is of course a judgment call.

Inherently fire resistive cables can be tested to UL 2196, Tests for Fire Resistive Cables, whereas enclosures for cables that are not inherently fire resistive can be tested to UL 1724 or USNRC Generic Letter 86-10, Supplement 1 in North America, or BS476 in the United Kingdom or DIN4102 in Germany.

For Petrochemical Industries, Offshore/ Onshore, API 2218 standards are referred as the fireproofing guidelines. API 2218 addresses the case of hydrocarbon fire as opposed to cellulosic fire curve used in DIN 4102 and BS 476 part 20 test standards for Buildings.

API 2218 ‘Fire Proofing Practices in Petroleum and Petrochemical Processing Plants’ references ASTM E1725-95 and UL 2196 test method for fire testing and requires the system to be rated to minimum 15 minutes up to 30 min. The fire test should be carried out using a rapid rise hydrocarbon fire temperature/time curve such as ASTM 1529 or UL 1709 ( both considered functionally equivalent). The ASTM E1529 curve is slightly higher in temperature than UL 1709 and specifies a heat flux taken from measurements of hydrocarbon pool fires.The ASTM E1725-95 test method has stringent requirements for performance of cable tray fire insulation systems as opposed to the circuit integrity requirement assessed in BS 476 part 20 and DIN 4102, such as the test is run at positive pressure, thermocouples are fixed into the tray, test is intended to be run empty of cables ( worst case) , providing approval for 0% to 100% cable loading and failure is determined when one thermocouple ‘set’ reaches an average temperature rise of 250 °F, (121 °C) or any single thermocouple reaches 325 °F (163 °C).

Products apart being tested, also needs to be certified by 3rd Party certifying bodies (FM / UL), as test reports may or may not be the representative of actual standards unless otherwise certified. Certification also ensures quality assurance as the product manufacturer as audited periodically.

Assessing the performance of cable tray fire insulation systems using cable tray temperature versus circuit integrity.

ASTM E1725 uses cable tray temperature as the failure criterion because circuit integrity has been shown to be unreliable as an indicator of failure of a cable for hydrocarbon fires.This is the result of research that indicated cables believed to be of identical composition and rating had different functional failure temperatures. This means that circuit integrity failure cannot be assumed to reliably occur at the same time point in a fire. Therefore, it is more reliable to establish a maximum temperature beyond which any cable can be considered to be at risk of failure. Using cable temperature as the failure criterion ensures that the maximum temperature at which functionality of any cable can be assumed to be maintained is not exceeded, even if circuit integrity can be maintained by the sample cable used in the fire test. Furthermore, the measurement of tray rather than cable temperature, with an empty tray, allows any cable loading to be used in practice.

Importantly the cable tray is tested for structural stability which often is found to fail before the circuit integrity in Hydrocarbon fire cases. Hence cable enclosures ensures cable tray is tested along with cables and recommended as a better option.

The mechanical ducting precedent

The other grandfathered approach is drywall shaftwall systems. Drywall shaftwalls were tested as a flat wall, no corners, no turns. This approach has pretty much been negated for use around ductwork (i.e. pressurisation and grease ducting, which are required to have a fire-resistance rating) since the adoption of the more suitable ISO6944 test regime by ULC as well as Underwriters Laboratories, whereby a duct is suspended from a full scale floor slab and the enclosure is built around the duct (or an inherently fire resistant duct is similarly tested without an enclosure, since it already contains a layer of insulation), for a more realistic 3D configuration and exposure. Drywall shaftwall systems were entirely grandfathered for this application and ceased to be legally representative of due diligence the instant a properly and purposely tested system with bona fide listings became available. The same thing applies to circuit integrity enclosures.

For the mechanical ductwork, a Canadian entrepreneur got ISO6944 passed by the ULC Standards Council and then performed testing. This made all grandfathered systems legally indefensible.

This has yet to occur in Canada for circuit integrity, but it has long been standard construction work in Europe and also in the US, through work done by UL and other laboratories. Since UL is accredited by the Standards Council of Canada in Canada and its listings are considered public record up all over North America including Canada, one is ill-advised to use grandfathered systems for circuit integrity anywhere.

Importantly, drywall shaftwall systems have only been qualified as straight walls in panel furnaces, not 3D enclosures with corners.

Current test methods

Germany has standardised this sort of testing via DIN4102 Part 12, dated January 1991, Fire behaviour of building materials and elements, Fire resistance of electrical cable systems, Requirements and testing. Part 12 encompasses both enclosures for cabling and bus ducts, as well as inherently fire-resistive cables, such as mineral insulated cables. Enclosures for ductwork as well as wiring are a regular part of passive fire protection there. It is also not nearly as expensive as North American qualified approaches. Typically, lightweight mineral boards are used, such as calcium silicate and sodium silicate bonded vermiculite.

The North American state of the art is UL1724 Standard for Tests of Thermal Barrier Systems for Electrical System Components as well as its cousin, UL2196 Standard for Tests of Fire Resistive Cables. UL1724 had its origin with USNRC Generic Letter 86-10 Supplement 1, issued by the Nuclear Regulatory Commission. "Supplement 1" was to address lessons learned from the widely publicised Thermo-lag 330-1 scandal, following disclosures by whistleblower Gerald W. Brown, which resulted in Congressional hearings and a large amount of remedial work.

Supplement 1 is a particularly difficult and expensive test to pass. No testing is done in anything less than a full scale fire test, running easily into 6 figure costs per burn multiplied by all the applications one desires to test. In order to pass, one must test the smallest as well as the largest application (12" and 36" cable tray, 1/2" and 6" conduit). Accordingly, the approved materials are costly, as manufacturers must get a return on the large test investment.

In concept, it is simple to devise systems that will pass the test. As far back as the 1970s, it was apparent that when one uses enough high temperature qualified insulation, such as ceramic fibre, one is assured of a rating. However, this comes at the price of significant ampacity derating. Also, the concept that more fireproofing is better, was defeated by industry tests of Thermo-lag 330-1 (which is not a fibrous insulation). No matter what was done to this material (used for fireproofing purposes over electrical circuits in full scale fire testing) by various nuclear power plant owners (USNRC licensees) who sponsored extensive testing, where more of the old Thermo-lag was applied onto the older substrate, no satisfactory results were achieved. In order for licensees to come into compliance, other methods, replacements, overlays and MI Cable were used to fix the problem. Also, since the forerunner of this testing was the USNRC, and the commercial version of it (UL1724) has undergone various revisions, the UL systems listed in the UL Building Materials directory are not necessarily qualified to the latest USNRC compliant or the latest UL version. But that does not mean that the older listings are simply discarded or that the manufacturers performed all new tests. Therefore, users must closely review the versions of the tests deemed acceptable in an end-user facility.

Ampacity derating

Ampacity derating refers to the reduction of the ability of a cable to conduct electricity. It can be tested through the use of IEEE 848 Standard Procedure for the Determination of the Ampacity Derating of Fire-Protected Cables. The more one insulates a conductor, the less current it can conduct without damage from overheating. The result of the test referenced herein is quantified in terms of percentage. If a cable is derated by 30%, it can be used to conduct only 70% as much current, thus cable of greater cross sectional area is often needed to conduct a given amount of power. The use of intumescent "windows", which shut in case of a fire, can reduce or negate the effect of ampacity derating, subject to listing and approval use and compliance.

Applications of Circuit Integrity

Ordinarily, small runs of cables are individually run with cables that are fire-resistance rated on their own. Larger bundles and trays full of wiring may be less expensive to clad or wrap on the outside. The concrete cover method is most often used in Canadian construction, as the code and common practice permit this, despite the absence of testing data that gives the required "carte blanche" for all cables and indefinite ratings.

Cladding and wrapping considerations

The added weight of the wrap systems must be included in static and seismic calculations. Fireproofing of the hanging system must also be considered. Regular maintenance must be considered, as cladding and wraps are not load-bearing and can be damaged during normal building or facility operations. Ampacity-derating may be mitigated by the use of purpose-designed intumescent or mechanically/electronically activated "windows" that permit heat venting. Like everything else in passive fire protection, all such methods are subject to stringent listing and approval use and compliance.

Terminals and Junction box considerations

Termination points and junction boxes, in other words the entire circuit, must be completely protected. Often, termination points are left out, providing a weak link. Therefore, some enclosures are needed to be used in conjunction with MI cables. One may run MI cable into a box in an electrical room. However, just because that room may be a "service room" and may be subject to compartmentalization (fire protection), this does not mean one no longer requires a rated box or wrap around the electrical outlet box or junction box where the wiring is terminated because that box may be disabled as a result of a fire within the room. The probability of electrical fires are a strong motivating factor for compartmetalisation to begin with. The cable may thus be operable but the circuit as a whole may be defeated because the junction box would not have been protected. Such omissions are not entirely uncommon in the field.

For petrochemical Industries the junction box or cable terminations require the junction box to be rated same or higher to that of the cable tray. Hence it cab be protected with the similar enclosure system used in Cable tray wrap enclosure as the objective is to keep the temperature on the electrical components below a critical temperature limit to be operable.

See also

External links

| Wikimedia Commons has media related to Circuit integrity. |

- DIN 4102 Fire behaviour of building materials and building components - Part 12: Circuit integrity maintenance of electric cable systems; requirements and testing

- NRC treatise on circuit integrity measures

- USNRC Generic Letter 86-10 Supplement 1 - FIRE ENDURANCE TEST ACCEPTANCE CRITERIA FOR FIRE BARRIER SYSTEMS USED TO SEPARATE REDUNDANT SAFE SHUTDOWN TRAINS WITHIN THE SAME FIRE AREA (SUPPLEMENT 1 TO GENERIC LETTER 86-10, "IMPLEMENTATION OF FIRE PROTECTION REQUIREMENTS")

- ASTM E1725 - 08 Standard Test Methods for Fire Tests of Fire-Resistive Barrier Systems for Electrical System Components

- UL1724 - FIRE TESTS FOR ELECTRICAL CIRCUIT PROTECTIVE SYSTEMS

- IEEE 848 Standard Procedure for the Determination of the Ampacity Derating of Fire-Protected Cables.

- UL 2196 Fire-Resistive and Circuit Integrity Cables