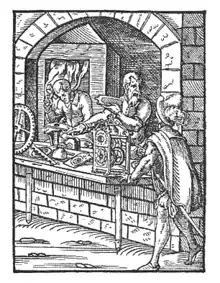

Clockmaker

A clockmaker is an artisan who makes and/or repairs clocks. Since almost all clocks are now factory-made, most modern clockmakers only repair clocks. Modern clockmakers may be employed by jewellers, antique shops, and places devoted strictly to repairing clocks and watches. Clockmakers must be able to read blueprints and instructions for numerous types of clocks and time pieces that vary from antique clocks to modern time pieces in order to fix and make clocks or watches. The trade requires fine motor coordination as clockmakers must frequently work on devices with small gears and fine machinery.

Originally, clockmaker were master craftsmen who designed and built clocks by hand. Since modern clockmakers are required to repair antique, handmade or one-of-a-kind clocks for which parts are not available, they must have some of the design and fabrication abilities of the original craftsmen. A qualified clockmaker can typically design and make a missing piece for a clock without access to the original component.

Clockmakers generally do not work on watches; the skills and tools required are different enough that watchmaking is a separate field, handled by another specialist, the watchmaker.

Origins and specialities

The earliest use of the term clokkemaker is said to date from 1390, about a century after the first mechanical clocks appeared.[1] From the beginning in the 15th century through the 17th century, clockmaking was considered the "leading edge", most technically advanced trade existing. Historically, the best clockmakers often also built scientific instruments, as for a long time they were the only craftsmen around trained in designing precision mechanical apparatus. In one example, the harmonica was invented by a young German clockmaker, which was then mass-produced by another clockmaker, Matthias Hohner.

Prior to 1800 clocks were entirely handmade, including all their parts, in a single shop under a master clockmaker. Examples of these complex movements can be seen in the many longcase clocks constructed in the 16th and 17th centuries. By the 19th century, clock parts were beginning to be made in small factories, but the skilled work of designing, assembling, and adjusting the clock was still done by clockmaking shops. By the 20th century, interchangeable parts and standardized designs allowed the entire clock to be assembled in factories, and clockmakers specialized in repair of clocks.

Guilds

As the art of making clocks became more widespread and distinguished, guilds specifically for this trade emerged around the sixteenth century. One of the first guilds developed in London, England, known as the Worshipful Company of Clockmakers; the group formed after a small number of foreign-trained clockmakers spent time working in London.[2] A requirement of joining the guild was to practise their craft and gain as much experience as possible, along with joining one of many other trade guilds, such as the Blacksmiths, Stationers, or Drapers Company. There are many guilds where clockmakers meet to buy, sell and get clocks to repair from customers, the IWJG is one of the most prominent in the world.

Tools

Early clockmakers fashioned all the intricate parts and wheelwork of clocks by hand, using hand tools. They developed specialized tools to help them.[3]

- Balance Truing Caliper: This device was used in fashioning the wheels and gearwork of the clock, to make sure the wheel, particularly the balance wheel was balanced and circular. The pivots of the wheel were mounted in the caliper. An index arm was moved next to the edge and the wheel was spun to see if the edge was true.

- Die/Screw Plate: The die plate was used to cut threads on small screws. It had a number of threaded die holes of different sizes for making different threads. A piece of wire was inserted in a hole and turned to cut a thread on the end. Then a head would be formed on the other end of the wire to make a screw.

- File: Hardened steel files were used to shape the metal before it was used to make and fit wheels or plates. There were many variations of files.

- Rivet Extracting Pliers: Made of brass or steel, rivet extracting pliers were used to remove rivets from assorted clock parts.

- Jeweler’s Piercing Saw: The blade of the saw was released by undoing the thumbscrew adjacent to the handle. To start an interior cut, a hole was drilled and the blade was inserted and reattached to the saw. This device was popular among clockmakers to repair the ends of clock hands.

- Staking tool: An iron vertical plunger was used with an array of stakes for placing rollers and balanced wheels on staffs.

- Turns: The "turns" was a small bow-operated lathe used for furbishing parts and for working gear blanks to size. During use, the device was clamped in a vise and the worker held a cutting or polishing tool on a tee-shaped tool rest with one hand, and shifted the bow back and forth to spin the part.

- Cross Peen Riveting Hammer: The flat end of the tool was for general use, whereas the radiused peen end was used for flattening rivet heads. This tool was used for forging, riveting, striking steel, etc.

Other uses

Clockmaker is also the name of several movies.[4]

Deists often call God the "Clockmaker". The Temple of the Great Clockmaker, in the novel The Case Of The Dead Certainty by Kel Richards, is a temple which represents deism.

The Clock Maker Theory and the watchmaker analogy describe by way of analogy religious, philosophical, and theological opinions about the existence of god(s) that have been expressed over the years.

During the 1800s and 1900s, clocks or watches were carried around as a form of flaunting social status. They were also a way of instilling a sense of time regulation for work in the budding industrial market.

In 2004, Jim Krueger wrote a comic book entitled The Clock Maker, published by German publisher Image Publishing, that focuses on the life of a clockmaker.

Artist Tony Troy creates the Illustration titled "The Clockmaker" in 2003 for his Broadway musical "The Fluteplayer's Song".[5]

Notable clockmakers

- John Arnold, United Kingdom

- Johann Baptist Beha, Germany

- Ferdinand Berthoud, France and Switzerland

- Abraham Louis Breguet, France and Switzerland

- Achille Brocot, France

- Martin Burgess, United Kingdom

- Joost Bürgi, Switzerland

- Konstantin Chaykin, Russia

- Salomon Coster, Netherlands

- Antoine Cronier, Paris

- Aaron Lufkin Dennison, United Kingdom

- Giovanni de Dondi, Italy

- Richard Donisthorp, United Kingdom

- Hans Düringer, Germany

- John Ellicott, United Kingdom

- Eugène Farcot, France

- George Graham, United Kingdom

- David Hare, Scottish philanthropist and pioneer of modern European Education in India

- John Harrison, United Kingdom

- Peter Henlein, Germany

- Peter Hill (1767-1820), African-American clockmaker.[6]

- Tim Hunkin (made the London Zoo Clock and the Southwald Water Clock) United Kingdom[7]

- Christiaan Huygens, Netherlands

- James Ivory, United Kingdom

- Antide Janvier, France

- Mikulas of Kadan

- Franz Ketterer, Germany

- J. B. Joyce & Company, United Kingdom

- Johann Andreas Klindworth, Germany

- Joseph Knibb, United Kingdom

- Lazar the Hilandarian, late 14th- and early 15th-century Serbia and Russia

- Jean-Antoine Lépine, Franc

- Pierre Le Roy, France

- Jens Olsen, Denmark

- Timothy Mason (clockmaker), United Kingdom

- William Potts & Sons, United Kingdom

- Sigmund Riefler, Germany

- David Rittenhouse, United States

- Rasmus Sørnes, Norway

- Adolf Scheibe, Germany

- Su Song, China

- Smith of Derby Group, United Kingdom

- Thwaites & Reed, United Kingdom

- Eli Terry, United States

- John Tolson (clockmaker), United Kingdom

- Thomas Tompion, United Kingdom

- Benjamin Vulliamy, United Kingdom

- Richard of Wallingford, United Kingdom

- Simon Willard, United States

- John Whitehurst, United Kingdom

- George Garner, United States

- Michelangelo Sapiano, Malta

- G Bernard Ramsdale, United Kingdom

Clockmaking organizations

See also

References

- "Clock". Encyclopedia of Antiques. Old and Sold Antique Marketplace. Retrieved 2008-04-20.

- Mones, Richard Ann; George White (2012). "Worshipful Company of Clockmakers". Antiques and Fine Art magazine. antiquesandfineart.com. Archived from the original on March 4, 2016. Retrieved August 2, 2012.

- Carla, Ojha (2002). "Tools of the Clockmaker". Highlights of Past Exhibits. Museum of Early Trades and Crafts website. Archived from the original on August 14, 2012. Retrieved August 2, 2012.

- "Clockmaker". 18 August 1998 – via IMDb.

- Smith, Jessie Carney (2003). Black Firsts : 4,000 Ground-Breaking and Pioneering Historical Events (2nd, revised and expanded ed.). Canton, Michigan: Visible Ink Press. pp. 591–592. ISBN 1-57859-142-2. OCLC 51060259 – via Internet Archive.

- "tim hunkin home page". timhunkin.com.

External links

![]() Media related to Clockmakers at Wikimedia Commons

Media related to Clockmakers at Wikimedia Commons