Firing pin

A firing pin or striker is part of the firing mechanism used in a firearm or explosive device, designed to ignite combustions/detonations by delivering an impact force to shock-sensitive compounds known as primers. Firing pins may take many forms, though the types used in fuzes for single-use devices (such as landmines, artillery shells, cluster munitions and grenades) generally have a sharpened point. In contrast, firing pins used in firearms usually have a small, rounded portion designed to strike the primer of a cartridge, detonating the priming compound, which then ignites the propellant (inside) or fires the detonator and booster.[1][2][3]

Typically, firing pins or strikers are made from steel, aluminum or titanium. However, for specialist applications such as zero metal mines, non-metallic materials are used such as glass ceramic.

Firing pin vs. striker

A firing pin per se is a lightweight rod which only serves to transfer the momentum received from a spring-loaded hammer, in the same fashion a punch/chisel will relay the blow from a mallet. A striker is a hybrid piece directly connected to a spring, and is usually heavier and bulkier, without needing a separate hammer. Striker mechanisms are generally simpler, since they combine both functions of hammer and firing pin in one piece.[1]

The firing pin or striker is generally located in the bolt of a repeating firearm. Firearms that do not have bolts, such as revolvers and many types of single-shot firearms, generally have a very short firing pin in the action frame, or else attached to the hammer itself. These types of firearms are almost never striker-fired, as there is insufficient space to house a striker mechanism. Strikers are most commonly found in semi-automatic pistols and bolt-action firearms.[1]

Firing pin construction

The typical firing pin is a small simple rod with a hardened, blunted/rounded tip that strikes and crushes the primer. The rounded end ensures the primer is indented rather than pierced, as would otherwise happen if the firing pin were sharply pointed. Most firing pins are connected to a return spring to pushes them back and out of contact with the primer, and often will have an integrated passive safety mechanism such as a catch that blocks them from moving forward unless the trigger is depressed, or a transfer bar (also trigger-actuated) that must be in place to allow the hammer to impact the firing pin. This integrated safety is in addition to any manually operated safety mechanisms that deactivate the trigger or hammer.[4]

Handguns with reciprocating actions such as semi-automatic pistols, will often use a firing pin that is too short to project when depressed flush by the hammer. This type of firing pin, called an inertial firing pin, must be struck by a full fall of the hammer to provide enough forward momentum to reach and strike the primer. If the hammer is down, resting on the firing pin, it is very unlikely that an external blow to the rear will provide enough kinetic energy to the firing pin to detonate the primer. Most variants of the M1911 pistol use this type of firing pin.[2]

Many firing pins are stamped from sheet steel, forming a rectangular cross-section rather than a round one. These will often have a cylindrical section at the front rather than a hemispherical one and are fairly common in rimfire firearms. Sturm, Ruger & Co., for example, uses sheet metal firing pins in its 10/22 carbine and Mark II pistol.

High performance firing pins are often made from materials lighter than steel, such as titanium. The lighter mass increases the travel speed nd reduces the lock time, i.e. the time from trigger pull to the bullet leaving the barrel. There is some controversy as to whether or not such firing pins are really necessary, with some claiming them to impact more weakly than the regular steel ones.

Striker construction

Strikers are basically spring-loaded firing pins, generally of a one- or two-piece construction. In the one-piece striker, the striker is turned on a lathe out of a round bar of metal, much larger in diameter than a firing pin, to provide the mass required to detonate the primer. Two-piece strikers generally consist of a firing pin attached to a heavier rear section—in essence a hammer attached to the base of a firing pin. Two-piece strikers are commonly found in bolt-action rifles, while single-piece strikers are found in pistols, such as the Glock.[3] Some self-loading rifles, like the vz. 58, AN-94, and VSS Vintorez (as well as its derivative AS Val) use one or two-piece striker mechanisms rather than a rotating hammer.

Other uses

Mechanisms involving firing pins can be used also in other pyrotechnical systems, ranging from hand grenades to chemical oxygen generators.

Images

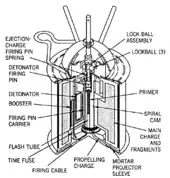

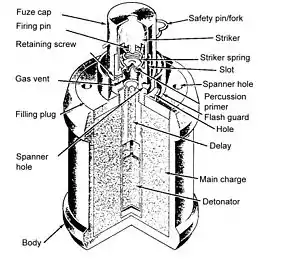

Cutaway view of a Russian F1 fragmentation grenade showing firing pin

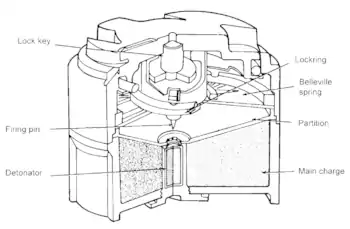

Cutaway view of a Russian F1 fragmentation grenade showing firing pin Cutaway view of an M4 anti-tank mine showing integral firing pin

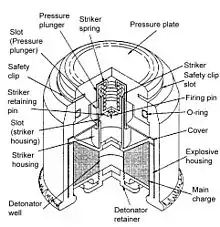

Cutaway view of an M4 anti-tank mine showing integral firing pin

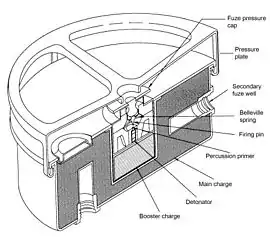

PM-79 antipersonnel mine

PM-79 antipersonnel mine

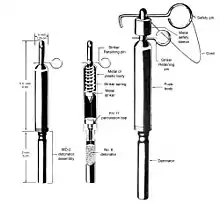

USSR boobytrap firing device—pressure fuze: victim steps on loose floorboard with fuze concealed underneath.

USSR boobytrap firing device—pressure fuze: victim steps on loose floorboard with fuze concealed underneath. Cross-sectional view of a BLU-43 Dragontooth cluster munition showing firing pin, detonator and adjacent explosive booster charge

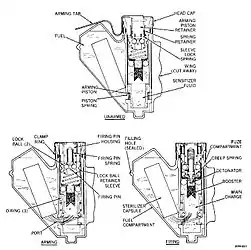

Cross-sectional view of a BLU-43 Dragontooth cluster munition showing firing pin, detonator and adjacent explosive booster charge Cross-sectional view of a Japanese Type 99 grenade showing firing pin.

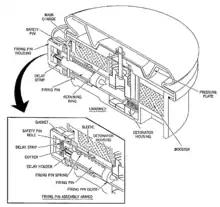

Cross-sectional view of a Japanese Type 99 grenade showing firing pin. Cross-sectional view of the fuze fitted to a German S-mine

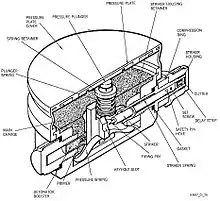

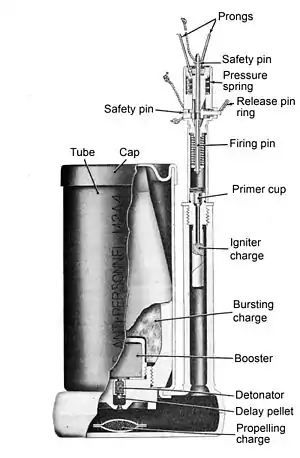

Cross-sectional view of the fuze fitted to a German S-mine Cross-sectional view of an American M2 mine

Cross-sectional view of an American M2 mine

References

- Charles E. Petty. "XD X-Deelicious!". American Cop. Archived from the original on July 23, 2008.

- "SAAMI Glossary, F". SAAMI. Archived from the original on 2008-01-31. Retrieved 2008-02-12.

- "SAAMI Glossary, S". SAAMI.

- "Definition of 'transfer bar'". MidwayUSA GunTec Dictionary. Archived from the original on 2009-07-16. Retrieved 2008-02-12.