Heusler compound

Heusler compounds are magnetic intermetallics with face-centered cubic crystal structure and a composition of XYZ (half-Heuslers) or X2YZ (full-Heuslers), where X and Y are transition metals and Z is in the p-block. Many of these compounds exhibit properties relevant to spintronics, such as magnetoresistance, variations of the Hall effect, ferro-, antiferro-, and ferrimagnetism, half- and semimetallicity, semiconductivity with spin filter ability, superconductivity, and topological band structure. Their magnetism results from a double-exchange mechanism between neighboring magnetic ions. Manganese, which sits at the body centers of the cubic structure, was the magnetic ion in the first Heusler compound discovered. (See the Bethe–Slater curve for details of why this happens.)

Discovery and properties

The term derives from the name of German mining engineer and chemist Friedrich Heusler, who studied such a compound in 1903.[1] It contained two parts copper, one part manganese, and one part aluminium, that is Cu2MnAl, and has the following properties. Its magnetism varies considerably with heat treatment and composition.[2] It has a room-temperature saturation induction of around 8,000 gauss, which exceeds that of the element nickel (around 6100 gauss) but is smaller than that of iron (around 21500 gauss). For early studies see.[1][3][4] In 1934, Bradley and Rogers showed that the room-temperature ferromagnetic phase was a fully ordered structure of the L21 Strukturbericht type.[5] This has a primitive cubic lattice of copper atoms with alternate cells body-centered by manganese and aluminium. The lattice parameter is 5.95 Å. The molten alloy has a solidus temperature of about 910 °C. As it is cooled below this temperature, it transforms into disordered, solid, body-centered cubic beta-phase. Below 750 °C, a B2 ordered lattice forms with a primitive cubic copper lattice, which is body-centered by a disordered manganese-aluminium sublattice.[2][6] Cooling below 610 °C causes further ordering of the manganese and aluminium sub-lattice to the L21 form.[2][7] In non-stoichiometric alloys, the temperatures of ordering decrease, and the range of anealing temperatures, where the alloy does not form microprecipitates, becomes smaller than for the stoichiometric material.[8][9][2]

Oxley found a value of 357 °C for the Curie temperature, below which the compound becomes ferromagnetic.[10] Neutron diffraction and other techniques have shown that a magnetic moment of around 3.7 Bohr magnetons resides almost solely on the manganese atoms.[2][11] As these atoms are 4.2 Å apart, the exchange interaction, which aligns the spins, is likely indirect and is mediated through conduction electrons or the aluminium and copper atoms.[10][12]

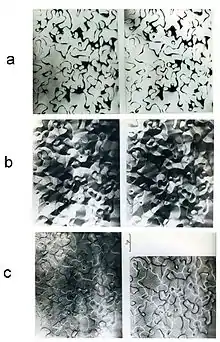

Electron microscopy studies demonstrated that thermal antiphase boundaries (APBs) form during cooling through the ordering temperatures, as ordered domains nucleate at different centers within the crystal lattice and are often out of step with each other where they meet.[2][6] The anti-phase domains grow as the alloy is annealed. There are two types of APBs corresponding to the B2 and L21 types of ordering. APBs also form between dislocations if the alloy is deformed. At the APB the manganese atoms will be closer than in the bulk of the alloy and, for non-stoichiometric alloys with an excess of copper (e.g. Cu2.2MnAl0.8), an antiferromagnetic layer forms on every thermal APB.[13] These antiferromagnetic layers completely supersede the normal magnetic domain structure and stay with the APBs if they are grown by annealing the alloy. This significantly modifies the magnetic properties of the non-stoichiometric alloy relative to the stoichiometric alloy which has a normal domain structure. Presumably this phenomenon is related to the fact that pure manganese is an antiferromagnet although it is not clear why the effect is not observed in the stoichiometric alloy. Similar effects occur at APBs in the ferromagnetic alloy MnAl at its stoichiometric composition.

Some Heusler compounds also exhibit properties of materials known as ferromagnetic shape-memory alloys. These are generally composed of nickel, manganese and gallium and can change their length by up to 10% in a magnetic field.[14]

Mechanical properties

Understanding the mechanical properties of Heusler compounds is paramount for temperature-sensitive applications (e.g. thermoelectrics) for which some sub-classes of Heusler compounds are used. However, experimental studies are rarely encountered in literature.[15] In fact, the commercialization of these compounds is limited by the material’s ability to undergo intense, repetitive thermal cycling and resist cracking from vibrations. An appropriate measure for crack resistance is the material’s toughness, which typically scales inversely with another important mechanical property: the mechanical strength. In this section, we highlight existing experimental and computational studies on the mechanical properties of Heusler alloys. Note that the mechanical properties of such a compositionally-diverse class of materials is expectedly dependent on the chemical composition of the alloys themselves, and therefore trends in mechanical properties are difficult to identify without a case-by-case study.

The elastic modulus values of half-Heusler alloys range from 83 to 207 GPa, whereas the bulk modulus spans a tighter range from 100 GPa in HfNiSn to 130 GPa in TiCoSb.[15] A collection of various density functional theory (DFT) calculations show that half-Heusler compounds are predicted to have a lower elastic, shear, and bulk modulus than in quaternary-, full-, and inverse-Hausler alloys.[15] DFT also predicts a decrease in elastic modulus with temperature in Ni2XAl (X=Sc, Ti, V), as well as an increase in stiffness with pressure.[16] The decrease in modulus with respect to temperature is also observed in TiNiSn, ZrNiSn, and HfNiSn, where ZrNiSn has the highest modulus and Hf has the lowest.[17] This phenomenon can be explained by the fact that the elastic modulus decreases with increasing interatomic separation: as temperature increases, the atomic vibrations also increase, resulting in a larger equilibrium interatomic separation.

The mechanical strength is also rarely studied in Heusler compounds. One study has shown that, in off-stoichiometric Ni2MnIn, the material reaches a peak strength of 475 MPa at 773 K, which drastically reduces to below 200 MPa at 973 K.[18] In another study, a polycrystalline Heusler alloy composed of the Ni-Mn-Sn ternary composition space was found to possess a peak compressive strength of about 2000 MPa with plastic deformation up to 5%.[19] However, the addition of Indium to the Ni-Mn-Sn ternary alloy not only increases the porosity of the samples, but it also reduces the compressive strength to 500 MPa. It is unclear from the study what percentage of the porosity increase from the Indium addition reduces the strength. Note that this is opposite to the outcome expected from solid solution strengthening, where adding Indium to the ternary system slows dislocation movement through dislocation-solute interaction and subsequently increases the material's strength.

The fracture toughness can also be tuned with composition modifications. For example, the average toughness of Ti1-x(Zr, Hf)xNiSn ranges from 1.86 MPa m1/2 to 2.16 MPa m1/2, increasing with Zr/Hf content.[17] The preparation of samples may affect the measured fracture toughness however, as elaborated by O’Connor et al.[20] In their study, samples of Ti0.5Hf0.5Co0.5Ir0.5Sb1-xSnx were prepared using three different methods: a high-temperature solid state reaction, high-energy ball milling, and a combination of both. The study found higher fracture toughness in samples prepared without a high-energy ball milling step of 2.7 MPa m1/2 to 4.1 MPa m1/2, as opposed to samples that were prepared with ball milling of 2.2 MPa m1/2 to 3.0 MPa m1/2.[17][20] Fracture toughness is sensitive to inclusions and existing cracks in the material, so it is as expected dependent the sample preparation.

List of notable Heusler compounds

- Cu2MnAl, Cu2MnIn, Cu2MnSn

- Ni2MnAl, Ni2MnIn, Ni2MnSn, Ni2MnSb, Ni2MnGa

- Co2MnAl, Co2MnSi, Co2MnGa, Co2MnGe, Co2NiGa

- Pd2MnAl, Pd2MnIn, Pd2MnSn, Pd2MnSb

- Co2FeSi, Co2FeAl[21]

- Fe2VAl

- Mn2VGa, Co2FeGe[22]

- Co2CrxFe1-xX(X=Al, Si)[23]

References

- Heusler F. (1903). "Über magnetische Manganlegierungen". Verhandlungen der Deutschen Physikalischen Gesellschaft (in German). 12: 219.

- Bouchard M. (1970). "Electron metallography and magnetic properties Cu-Mn-Al heusler alloys". Ph.D. Thesis, Imperial College London.

- Knowlton, A. A; Clifford, O. C (1912). "The Heusler alloys". Transactions of the Faraday Society. 8: 195. doi:10.1039/TF9120800195.

- Bozorth, Richard M. (1993). Ferromagnetism. Wiley-VCH. p. 201. ISBN 978-0-7803-1032-2.

- Bradley, A. J; Rodgers, J. W (1934). "The Crystal Structure of the Heusler Alloys". Proceedings of the Royal Society A: Mathematical, Physical and Engineering Sciences. 144 (852): 340–59. Bibcode:1934RSPSA.144..340B. doi:10.1098/rspa.1934.0053.

- Nesterenko, E.G.; Osipenko, I.A.; Firstov, S.A. (1969). "Structure of Cu-Mn-Al Ordered Alloys". Physics of Metals and Metallography. 27 (1): 135–40.

- Ohoyama, T; Webster, P J; Tebble, R S (1968). "The ordering temperature of Cu2MnAl". Journal of Physics D: Applied Physics. 1 (7): 951. Bibcode:1968JPhD....1..951O. doi:10.1088/0022-3727/1/7/421.

- West D.R.F.; Lloyd Thomas D. (1956). "The constitution of copper rich alloys of the copper-manganese-aluminum system". Journal of Industrial Metals. 85: 97.

- Johnston, G.B; Hall, E.O (1968). "Studies on the Heusler alloys—I. Cu2MnAl and associated structures". Journal of Physics and Chemistry of Solids. 29 (2): 193–200. Bibcode:1968JPCS...29..193J. doi:10.1016/0022-3697(68)90062-0.

- Oxley, D. P; Tebble, R. S; Williams, K. C (1963). "Heusler Alloys". Journal of Applied Physics. 34 (4): 1362. Bibcode:1963JAP....34.1362O. doi:10.1063/1.1729511.

- Endō, Keizo; Ohoyama, Tetuo; Kimura, Ren'iti (1964). "On the Magnetic Moment of Mn in Aluminum Heusler Alloy". Journal of the Physical Society of Japan. 19 (8): 1494. Bibcode:1964JPSJ...19.1494E. doi:10.1143/JPSJ.19.1494.

- Geldart, D. J. W; Ganguly, P (1970). "Hyperfine Fields and Curie Temperatures of the Heusler Alloys Cu2MnAl, Cu2MnIn, and Cu2MnSn". Physical Review B. 1 (7): 3101–8. Bibcode:1970PhRvB...1.3101G. doi:10.1103/PhysRevB.1.3101.

- Lapworth, A. J; Jakubovics, J. P (2006). "Effect of antiphase boundaries on the magnetic properties of Cu-Mn-Al Heusler alloys". Philosophical Magazine. 29 (2): 253. Bibcode:1974PMag...29..253L. doi:10.1080/14786437408213271.

- Sakon, Takuo; Otsuka, Kohei; Matsubayashi, Junpei; Watanabe, Yuushi; Nishihara, Hironori; Sasaki, Kenta; Yamashita, Satoshi; Umetsu, Rie; Nojiri, Hiroyuki; Kanomata, Takeshi (2014). "Magnetic Properties of the Ferromagnetic Shape Memory Alloys Ni50+xMn27−xGa23 in Magnetic Fields". Materials. 7 (5): 3715–3734. Bibcode:2014Mate....7.3715S. doi:10.3390/ma7053715. PMC 5453230. PMID 28788645.

- Everhart, Wesley; Newkirk, Joseph (2019-05-01). "Mechanical properties of Heusler alloys". Heliyon. 5 (5): e01578. doi:10.1016/j.heliyon.2019.e01578. ISSN 2405-8440. PMID 31080903.

- Wen, Zhiqin; Zhao, Yuhong; Hou, Hua; Wang, Bing; Han, Peide (2017-01-15). "The mechanical and thermodynamic properties of Heusler compounds Ni2XAl (X=Sc, Ti, V) under pressure and temperature: A first-principles study". Materials & Design. 114: 398–403. doi:10.1016/j.matdes.2016.11.005. ISSN 0264-1275.

- Rogl, G.; Grytsiv, A.; Gürth, M.; Tavassoli, A.; Ebner, C.; Wünschek, A.; Puchegger, S.; Soprunyuk, V.; Schranz, W.; Bauer, E.; Müller, H. (2016-04-01). "Mechanical properties of half-Heusler alloys". Acta Materialia. 107: 178–195. doi:10.1016/j.actamat.2016.01.031. ISSN 1359-6454.

- Musabirov, I. I.; Safarov, I. M.; Nagimov, M. I.; Sharipov, I. Z.; Koledov, V. V.; Mashirov, A. V.; Rudskoi, A. I.; Mulyukov, R. R. (2016-08-01). "Fine-grained structure and properties of a Ni2MnIn alloy after a settling plastic deformation". Physics of the Solid State. 58 (8): 1605–1610. doi:10.1134/S1063783416080217. ISSN 1090-6460. S2CID 126021631.

- Maziarz, W.; Wójcik, A.; Grzegorek, J.; Żywczak, A.; Czaja, P.; Szczerba, M. J.; Dutkiewicz, J.; Cesari, E. (2017-08-25). "Microstructure, magneto-structural transformations and mechanical properties of Ni50Mn37.5Sn12.5-xInx (x=0, 2, 4, 6 % at.) metamagnetic shape memory alloys sintered by vacuum hot pressing". Journal of Alloys and Compounds. 715: 445–453. doi:10.1016/j.jallcom.2017.04.280. ISSN 0925-8388.

- O'Connor, C.J. (2012). "Nanostructured Composite Materials for High Temperature Thermoelectric Energy Conversion, Final Technical Report, DARPA Grant No. HR0011-08-0084" – via Advanced Materials Research Institute, University of New Orleans. Cite journal requires

|journal=(help) - Husain, Sajid; Akansel, Serkan; Kumar, Ankit; Svedlindh, Peter; Chaudhary, Sujeet (2016). "Growth of Co2FeAl Heusler alloy thin films on Si(100) having very small Gilbert damping by Ion beam sputtering". Scientific Reports. 6: 28692. Bibcode:2016NatSR...628692H. doi:10.1038/srep28692. PMC 4928049. PMID 27357004.

- Ramesh Kumar, K; Kamala Bharathi, K; Arout Chelvane, J; Venkatesh, S; Markandeyulu, G; Harishkumar, N (2009). "First-Principles Calculation and Experimental Investigations on Full-Heusler Alloy Co2FeGe". IEEE Transactions on Magnetics. 45 (10): 3997–9. Bibcode:2009ITM....45.3997K. doi:10.1109/TMAG.2009.2022748. S2CID 33360474.

- Guezlane Mourad, H; Baaziz, Z; Charifi, Y; Djaballah (2016). "Electronic, magnetic and thermal properties of Co2CrxFe1-xX(X=Al, Si) Heusler alloys: First-principles calculations". Magnetism and Magnetic Materials. 414: 219–226. Bibcode:2016NatSR...628692H. doi:10.1016/j.jmmm.2016.04.056.

Further reading

- G. Sauthoff: Intermetallics, Wiley-VCH, Weinheim 1995, S. 83 u. 90.

- Block, T; Carey, M. J; Gurney, B. A; Jepsen, O (2004). "Band-structure calculations of the half-metallic ferromagnetism and structural stability of full- and half-Heusler phases". Physical Review B. 70 (20): 205114. Bibcode:2004PhRvB..70t5114B. doi:10.1103/PhysRevB.70.205114.

- Webster, Peter J (1969). "Heusler alloys". Contemporary Physics. 10 (6): 559–577. Bibcode:1969ConPh..10..559W. doi:10.1080/00107516908204800.