KarTrak

KarTrak, sometimes KarTrak ACI (for Automatic Car Identification) is a colored bar code system designed to automatically identify rail cars and other rolling stock. KarTrak was made a requirement in North America, but technical problems led to abandonment of the system in the late 1970s.

History

In the late 1960s, railroads in North America began searching for a system that would allow them to automatically identify rail cars and other rolling stock. Through the efforts of the Association of American Railroads (AAR), a number of companies developed Automatic equipment identification (AEI) systems. The AAR selected four systems for extensive field tests. General Electric developed an RFID system, ABEX a microwave system, Wabco a black and white barcode system, and General Telephone and Electronics (GTE) a color barcode system called KarTrak. All those systems, except the RFID system, had labels that were mounted on each side of the rail car and a trackside scanner.

After the initial field tests, the ABEX, Wabco, and the GTE KarTrak ACI systems were selected for a head-to-head accuracy test on the Pennsylvania Railroad, at Spruce Creek PA. The KarTrak system was declared the winner and selected by the AAR as the standard.

Starting in 1967 all railcar owners were required by the AAR to install ACI labels on their cars. This requirement led to full-scale implementation of the ACI system in the early 1970s. By 1975 90% of all railcars were labeled. The read rate was about 80%, which means that after seven years of service 10% of the labels had failed for reasons such as physical damage and dirt accumulation. The dirt accumulation was most evident on flatcars that had low-mounted labels.

The AAR had recognized from their field tests that periodic inspection and label maintenance would be requirements to maintain a high level of label readability. Regulations were instituted for label inspection and repair whenever a railcar was in the repair shop, which on average happened every two years.

Unfortunately the maintenance program never gained sufficient compliance. Without maintenance the read rate failed to improve, and the KarTrak system was abandoned by 1977. Because of this failure, the railroad industry did not seriously search for another system to identify rail cars until the mid-1980s.

Design

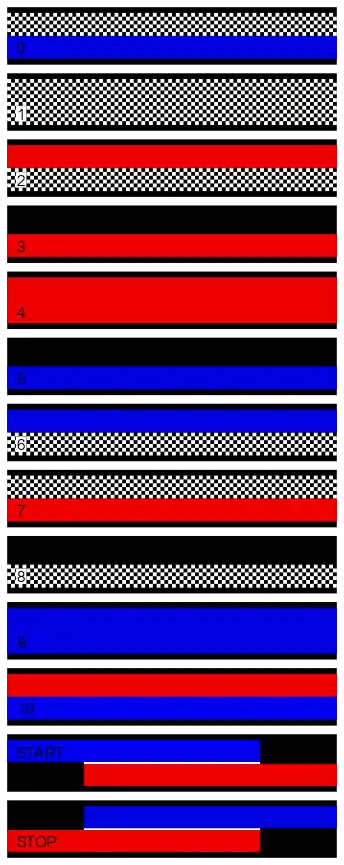

KarTrak ACI tags consisted of a plate with 13 horizontal labels, which could have 13 different forms. In addition to the labels for numbers 0-9, three special labels existed; start and stop labels to mark the beginning and end of the code, and "10" as a check label.[1]

The labels each are 5 3/4" wide and 1" high, and have a 3/8" vertical gap between them. Labels could be affixed directly to the car side, but usually were applied to a dark plate which was then riveted to each side of the car.[2]

The label stripes are made from retro-reflective plastic sheet that was coated with red or blue dye to provide distinguishable color filters. The retro-reflective material gave a clear optical signal that could be read from a 9-12 foot distance and easily distinguished from the other markings on the rail car. The white areas provided both a red and blue optical response to the reader and were patterned with dots so that their brightness would be about the same as a red or blue stripe.

The start and stop label strips were partially filled strips so that the reader scanning beam would be centered on them before they were recognized. This insured that the entire label was centered and had the best chance of being read accurately.

The labels are to be read from bottom to top:

- Line 13 - check digit.

- Line 12 - stop label.

- Lines 6 to 11 - car number.

- Lines 2 to 5 - equipment owner code.

- Line 1 - start label.

The first digit of the equipment owner (line 2) marks the type of equipment: 0 for railroad-owned, 1 for privately owned or 6 for non-revenue equipment.

The car number is padded with zeroes if necessary. For locomotives, line 6 is the type of unit and line seven the suffix number.

The parity check digit is calculated as follows: Each number digit is multiplied by two to the power of [the labels's position minus two]. Thus the first digit (second line) is multiplied by 1, the second by 2, the third by 4, the fourth by 8 and so on, until the 10th which is multiplied by 512. The sum of all these numbers modulo 11 is the check digit.[1]

The code on the caboose in the picture at top can be decoded as Start 8350199918 Stop 5. This means a car with equipment code number 8, ownership code 350, which lists this as a car of the Illinois Central Gulf Railroad,[3] and car number 199918, with 5 as check digit.

The readers were optical scanners somewhat like the bar code scanners used for grocery barcode items today. The scanning distances and speeds meant that the processing electronics needed to be state of the art for its day. They were placed along the rail lines, often at the entrance and exit of a switch yard, spaced back from the tracks so that the labels would pass in the reading zone that was 9 to 12 feet from the scanner.

The scanners were housed in metal boxes about the size of a mini-refrigerator. They consisted of a collimated 100-200 watt xenon arc light source arranged co-axially with a red and blue sensing photo tubes. The coaxial optical arrangement provided optimum sensing of the retro-reflective labels. This optical source and sensing beam was directed to a large (8" to 14") mirrored rotating wheel that provided the vertical scanning of the rail car. The movement of the train provided the horizontal scanning. Although the system could capture labels at 60 mph often the speeds were much slower.

The scanner analog video electrical signals were passed to a nearby rail equipment hut where the processing and computing electronics were located. The first systems were discrete circuits and logic and only provided a ASCII coded list of the labels that passed the scanner. These were forwarded to the rail operators for manual tracking or integration with their computer systems. Later reading systems were coupled with era mini computers (Digital Equipment Corporation PDP-8s)and more elaborate tracking and weighing systems were integrated. Sometimes these included many rail yard input sensors of rail switch position, car passage and hot wheel bearing sensors. Some of the more productive and thus longer lived systems were installed at captive rail applications that carried bulk goods from mines to smelter where the weight of individual cars loaded and unloaded tracked the bulk inventory.

Legacy

The KarTrak system proved to need too much maintenance to be practical. Up to 20% of the cars were not read correctly. This led to the abandonment of the system in the late 1970s. Between 1967 and 1977, the railroad industry spent $150 million on KarTrak and up to 95% of cars were barcoded.[4]

Older cars can often still be seen with a KarTrak label.

KarTrak label decals are readily available for different model railroad scales.

References

- Automatic Car Identification A.C.I.

- A guide to ACI (Automatic Car Identification)/Kar Trak labels

- Eric Neubauer's List of ACI Ownership codes

- Smith, Ernie (24 October 2017). "How the Railroad Industry Invented, Then Immediately Discarded, the Barcode". Motherboard. Vice Media. Retrieved 24 October 2017.