List of textile mills in Cheshire

This is a list of the silk, cotton and other textile mills in Cheshire, England. The first mills were built in the 1760s, in Styal by Samuel Greg using the Arkwright system and were powered by the water of the River Bollin. There were significant early cotton mills; Cheshire was an important centre of the silk industry. Parts of Cheshire have been subsumed into Stockport and Tameside.

River Bollin

Styal

| Name | Architect | Location | Built | Demolished | Served (Years) |

|---|---|---|---|---|---|

| Quarry Bank Mill | SJ834830 53°20′38″N 2°15′04″W | 1784 | Standing | 175 | |

|

Notes: This is one of the best preserved textile mills of the Industrial Revolution and is now a museum of the cotton industry. It has been designated by English Heritage as a Grade II* listed building.[1] The mill was founded by Samuel Greg in 1784[2] in the village of Styal on the River Bollin. Its original iron water wheel was designed by Thomas Hewes and built between 1816 and 1820. The over head shafts above the machines were attached to the water wheel by a belt. When the water wheel turned, the motion moved the belt and powered the machine. | ||||

Macclesfield

| Name | Architect | Location | Built | Demolished | Served (Years) | ||

|---|---|---|---|---|---|---|---|

| Albert Mill | SJ 9224 7399 53°15′46″N 2°07′04″W[3] | 1840 | 181 | ||||

| Notes: This mill was erected by the Brocklehursts when they diversified into silk spinning and power weaving. | |||||||

| Albion Mill | London Road SJ919729 53°15′11″N 2°07′23″W | ||||||

|

Notes: | ||||||

| Alma Mill | Crompton Road SJ 9106 7357 53°15′33″N 2°08′08″W[3] | ||||||

|

Notes: | ||||||

| Alma Mill | Pickford St. 53°15′27″N 2°07′17″W | ||||||

|

Notes: | ||||||

| Arbourhay Street Mill | SJ 9220 7403 53°15′48″N 2°07′06″W[3][6] | 1811–31 | |||||

| Notes: Pedimented Mill | |||||||

| Athey Street Mill | SJ 9126 7347 53°15′30″N 2°07′57″W[3] | ||||||

| Bank Street Works | SJ 9200 7315 53°15′19″N 2°07′17″W[3] | ||||||

| Bank Top Mill | SJ 9223 7319 53°15′21″N 2°07′04″W[3] | ||||||

| Barn Street Mill | unsited[3] | ||||||

| Bollinside Mill | SJ 9197 7331 53°15′24″N 2°07′18″W[3] | ||||||

| Bridge Street Mill | SJ 9142 7334 53°15′25″N 2°07′48″W[3] | 1811–31 | |||||

|

Notes: Pedimented Mill | ||||||

| Brook Mill | 53°15′21″N 2°07′08″W | ||||||

| Brookside Mill | SJ 9200 7332 53°15′24″N 2°07′17″W[3] | ||||||

|

Notes: | ||||||

| Brook Street Mills | SJ 9220 7328 53°15′23″N 2°07′06″W[3] | ||||||

|

Notes: | ||||||

| Brown Street Mill | Brown St SJ 9145 7311 53°15′18″N 2°07′47″W[3] | ||||||

|

|

||||||

| Brunswick Mill | Pickford St 53°15′28″N 2°07′30″W | ||||||

|

Notes: | ||||||

| Buckley Street Mill | SJ 9152 7305 53°15′16″N 2°07′43″W[3] | ||||||

|

Notes: | ||||||

| Byron House | London Road SJ919729 53°14′55″N 2°07′17″W | ||||||

|

Notes: | ||||||

| Catherine Street Mill | SJ 9152 7305 53°15′16″N 2°07′43″W[3] | ||||||

| Chapel Mill | 53°15′20″N 2°07′18″W | ||||||

|

Notes: | ||||||

| Charles Street Mill | SJ 9165 7334 53°15′25″N 2°07′36″W[3] | ||||||

| 19 Charles Street | SJ 916 734 53°15′29″N 2°07′37″W[3] | ||||||

| Charlotte Street | SJ 9185 7336 53°15′26″N 2°07′25″W[3] | ||||||

| Chestergate Mill | SJ9135 7362 53°15′34″N 2°07′52″W[3] | ||||||

| Clough Mill | SJ 9212 7306 53°15′16″N 2°07′11″W[3] | ||||||

| Commercial Road Mill | SJ 9195 7377 53°15′39″N 2°07′20″W[3] | ||||||

| Commercial Road/Queen Street Mill | SJ9195 7377 53°15′39″N 2°07′20″W[3] | ||||||

| Commongate Mill | SJ 9210 7364 53°15′35″N 2°07′12″W[3] | ||||||

| Croft Mill | SJ 9153 7353 53°15′31″N 2°07′42″W[3] | ||||||

| Crompton Road Mill | SJ911736 53°15′32″N 2°08′06″W | ||||||

|

Notes: | ||||||

| Cuckstool Pit Hill Mill | SJ 920 736 53°15′32″N 2°07′16″W[3] | ||||||

| Dale Street Mill | SJ 9230 7349 53°15′30″N 2°07′01″W[3] | ||||||

| Davenport Street Silk Machinery Factory Mill | SJ 9205 7345 53°15′29″N 2°07′14″W[3] | ||||||

| Depot Mill | SJ 9176 7334 53°15′25″N 2°07′30″W[3] | ||||||

| Dog Lane Mill | SJ 9165 7368 53°15′36″N 2°07′36″W[3] | ||||||

| Duke Street Mill | SJ 9173 7331 53°15′24″N 2°07′31″W[3] | ||||||

| 11 Duke Street | SJ 916 734 53°15′29″N 2°07′37″W[3] | ||||||

| Elizabeth Street Mill | SJ9152 7332 53°15′24″N 2°07′43″W[3] | ||||||

|

Notes: | ||||||

| Exchange Mill | SJ916 735 53°15′29″N 2°07′37″W[3] | ||||||

| Fud Shop | SJ9205 7394 53°15′45″N 2°07′14″W[3] | ||||||

| George Street Mill | SJ919729 53°15′11″N 2°07′23″W | ||||||

|

Notes: | ||||||

| George Street New Mill | SJ9195 7336 53°15′26″N 2°07′20″W[3] | ||||||

|

Notes: | ||||||

| Goodall Street Mill | SJ 9228 7326 53°15′23″N 2°07′02″W[3] | ||||||

| Gosling's, Mill | Pickford Street, SJ9180 7342 53°15′28″N 2°07′28″W[3] | ||||||

| Great King Street Mill | SJ9150 7357 53°15′33″N 2°07′44″W[3] | ||||||

| Green Street Mill | SJ9208 7343 53°15′28″N 2°07′13″W[3] | ||||||

| Grosvenor Street Mills | SJ 913 738 53°15′40″N 2°07′55″W[3] | ||||||

| Gutters Mill | SJ9183 7373 53°15′38″N 2°07′26″W[3] | ||||||

| Henderson Street Mill | SJ9135 7338 53°15′27″N 2°07′52″W[3] | ||||||

|

Notes: | ||||||

| Hibel Road Mill | SJ9205 7398 53°15′46″N 2°07′14″W[3] | ||||||

| Hines Factory | SJ920 730 53°15′14″N 2°07′16″W[3] | ||||||

| Hope Mill A & B | SJ 9157 7327 53°15′23″N 2°07′40″W[3] | ||||||

| Hurdsfield Road Mills | SJ9220 7403 53°15′48″N 2°07′06″W[3] | ||||||

| Johnson's Mill | unsited[3] | ||||||

| Jordangate Mill | unsited[3] | ||||||

| Kershaw | 53°15′28″N 2°07′53″W[3] | ||||||

|

Notes: | ||||||

| King Edward Street Mill | SJ9142 7382 53°15′41″N 2°07′48″W[3] | ||||||

|

Notes: | ||||||

| 30a King Edward Street | SJ 9154 7383 53°15′41″N 2°07′42″W[3] | ||||||

| King Street Mill | SJ9202 7379 53°15′40″N 2°07′16″W[3] | ||||||

| Knight's Mill | SJ922 731 53°15′18″N 2°07′05″W[3] | ||||||

|

Notes: | ||||||

| Knight Street Mill | 53°15′18″N 2°07′05″W[3] | ||||||

|

Notes: | ||||||

| Lansdowne Street Mills | SJ9220 7403 53°15′48″N 2°07′06″W[3] | ||||||

| Little Street Mill | SJ9148 7304 53°15′15″N 2°07′45″W[3] | ||||||

| London Road Mills | SJ 920 724 53°14′56″N 2°07′16″W[3] | ||||||

|

Notes: | ||||||

| Lowe Street Mill | SJ9194 7304 53°15′15″N 2°07′20″W[3] | ||||||

| Lower Beech Mill | unsited[3] | ||||||

| Lower Exchange Street B & F Mill | SJ9179 7347 53°15′30″N 2°07′28″W[3] | ||||||

| Lower Heyes Mill | SJ9194 7425 53°15′55″N 2°07′20″W[3] | ||||||

| Mill Street Mill | unsited[3] | ||||||

| Newgate Mill | SJ916 734 53°15′29″N 2°07′37″W[3] | ||||||

| Oxford Road Mill | SJ909735 53°15′29″N 2°08′17″W | ||||||

|

Notes: | ||||||

| Paradise Mills | SJ918732 53°15′22″N 2°07′26″W | 1860 | Standing | 161 | |||

|

Notes: Built around 1860. The mill was operated by Cartwright and Sheldon silk weavers from 1912 until 1981. It is now a museum displaying mill life in the 1930s, and 26 Jacquard Looms.[4] | ||||||

| Paradise Street Garret Loom Shops | 53°15′23″N 2°07′46″W | ||||||

|

Notes: This is a row of terraced houses each with a loom shop in the garret. Families used to enter the garret through a trap door | ||||||

| Park Green Mill | SJ919732 53°15′22″N 2°07′23″W[4] | ||||||

|

Notes: | ||||||

| Park Lane Mill | 53°15′22″N 2°07′31″W[6] | 1811–31 | |||||

| Notes: Pedimented Mill+ | |||||||

| Park Mill | SJ9165 7279 53°15′08″N 2°07′36″W[3] | 1852 | 169 | ||||

|

Notes: Pedimented Mill | ||||||

| Parr Street Shirt Mill | SJ9113 7349 53°15′30″N 2°08′04″W[3] | ||||||

| Peel Street Mill | SJ9170 7273 53°15′05″N 2°07′33″W[3] | ||||||

| Pickford Street Mills | Pickford St. 53°15′27″N 2°07′21″W[3][5] | ||||||

|

Notes: Including Pickford Street 'Á' Mill, Pickford Street 'B' Mill, Pickford Street Mill, Pickford Street New Mill 'B', | ||||||

| Pioneer Mill | SJ 9188 7336 53°15′26″N 2°07′24″W[7] | ||||||

| Pleasant Street Mill | SJ 9259 7425 53°15′55″N 2°06′45″W[7] | ||||||

| Pool Street Mill | SJ 9204 7289 53°15′11″N 2°07′15″W[7] | ||||||

| Progress Mill | 53°15′20″N 2°07′28″W[7] | ||||||

| Regency Mill | Chester Road, 53°15′35″N 2°08′16″W[6][7] | 1821–31 | |||||

|

Notes: Four storey pedimented Mill, aka Regency Mill. It was a steam-powered integrated mill including dyeing. The original occupiers were Hapgood and Parker. The steam engine produced 12hp. The main block is 37.5 x 8.00m., the floor separation being 3.00 m. | ||||||

| Rowbotham's Mill | SJ9203 7394 53°15′45″N 2°07′15″W[7] | ||||||

| Royal Button Mill | SJ 9194 7270 53°15′05″N 2°07′20″W[7] | ||||||

|

Notes: Pedimented Mill | ||||||

| Royal Court Mill | 53°15′25″N 2°07′19″W | ||||||

|

Notes: | ||||||

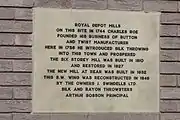

| Royal Depot Mills | SJ 9176 7334 53°15′25″N 2°07′30″W[8] | 1744 | 277 | ||||

|

Notes: 1744 Charles Roe built this mill in 1744 specifically to house Italian throwing machines which could produce organizine. Lombes patent on this device had expired in 1732, Logwood Mill in Stockport (then Cheshire) was built that year and Royal Button Mill was the second constructed in Cheshire. | ||||||

| Royal George Mills | SJ9134 7378 53°15′39″N 2°07′53″W[7] | ||||||

| Royal Silk Warehouse | SJ9188 7375 53°15′39″N 2°07′24″W[7] | ||||||

|

Notes: Extended and converted to a Travelodge Budget Hotel | ||||||

| Ryle Street Mill | SJ9209 7348 53°15′30″N 2°07′12″W[7] | ||||||

| St George's Street Mill | SJ9193 7285 53°15′09″N 2°07′21″W[7] | ||||||

| 3 St Georges St | SJ 9180 7310 53°15′17″N 2°07′28″W[3] | ||||||

| Samuel Street Mill | SJ9173 7326 53°15′23″N 2°07′31″W[7] | ||||||

| Short Street Mill | SJ9184 7365 53°15′35″N 2°07′26″W[7] | ||||||

| 5 Short St | SJ 9184 7365 53°15′35″N 2°07′26″W[3] | ||||||

| Silk Street Mill | SJ916 734 53°15′29″N 2°07′37″W[7] | ||||||

| Smales Mill | ??53°15′26″N 2°07′24″W | ||||||

|

Notes: | ||||||

| Soho Mill | SJ922 728 53°15′07″N 2°07′05″W[7] | ||||||

| Spring Gardens Mill | SJ916 745 53°16′01″N 2°07′37″W[7] | ||||||

| Stanley Street Mill | SJ9159 7373 53°15′38″N 2°07′39″W[7] | ||||||

| Sunderland Street Mill | Owner Pearson Family[7] |

SJ 9192 7348 53°15′30″N 2°07′21″W | |||||

| 47 Sunderland St | SJ 9189 7310 53°15′17″N 2°07′23″W[3] | ||||||

| Sunderland Street 'Slipper' Mill | [7] | SJ 9192 7352 53°15′31″N 2°07′21″W | |||||

| Sunnyside Mill | [7] | SJ 9192 7352 53°15′31″N 2°07′21″W | |||||

| Sutton Mill | SJ 9198 7276 53°15′06″N 2°07′18″W[7] | ||||||

|

Notes: | ||||||

| Thorp Street Gas Mill | SJ 9198 7387 53°15′42″N 2°07′18″W[6] | 1827 | reduced in height in 1977 | 150 | |||

| Notes: Pedimented Mill | |||||||

| Thorp Street Leather Mill | SJ 9194 7395 53°15′45″N 2°07′20″W[6] | ||||||

| Thorp Street Stoneley's Mill | SJ 9196 7389 53°15′43″N 2°07′19″W[6] | ||||||

| Townley Street Mill | 53°15′25″N 2°07′24″W | ||||||

|

Notes: | ||||||

| Union Mill | Elizabeth Street.[6] 53°15′21″N 2°07′46″W | 1811–31 | |||||

| Notes: Pedimented Mill- location uncertain, as the name is used by several mills. + | |||||||

| Union Street Mill | 53°15′24″N 2°07′41″W | 1890 | |||||

| Notes: Now a carpet warehouse, brick built on a grit-stone base+ | |||||||

| Victoria | Hursfield, 53°15′15″N 2°07′15″W[9] | 1830–40,1880–1890 | |||||

| Victoria Mills | SJ 9205 7300 53°15′14″N 2°07′14″W[7] | 1823 | Standing | 198 | |||

|

Notes: Victoria Mills, Cross Street, Windmill Street. Built for Winkworth and Proctor. The central block was from 1823, the big mill was 1837, and to the left of the chimney is the 1870 mill. | ||||||

| Vincent Street Mill | SJ 9167 7315 53°15′19″N 2°07′35″W[7] | ||||||

| Vincent Street New Mill | SJ 9311 9162 53°25′17″N 2°06′18″W[7] | ||||||

| Wardle Street Mill | 53°15′21″N 2°07′31″W[6] | 1811–31 | |||||

| Notes: Pedimented Mill+ | |||||||

| Waterloo Street Mill | SJ 919 737 53°15′36″N 2°07′23″W[7] | ||||||

| Waters Green (Hadfields) Mill | SJ 9202 7379 53°15′40″N 2°07′16″W[7] | ||||||

| Waters Green | 53°15′33″N 2°07′23″W[7] | ||||||

|

Notes: Including: Waters Green Mill, Waters Green Mill 'A', Waters Green Mill 'B', Waters Green New Mill. Pedimented Mill | ||||||

| Waterside Mill | SJ 921 731 53°15′18″N 2°07′12″W[7] | ||||||

| Wellington Mill | SJ 918 735 53°15′29″N 2°07′26″W[7] | ||||||

| Whiston Street Mill | SJ9118 7338 53°15′27″N 2°08′01″W[7] | ||||||

| Whitening Croft Mill | SJ 9304 7383 53°15′41″N 2°06′21″W[7] | ||||||

| Wilshaw Mill | SJ920724 53°14′56″N 2°07′16″W[4] | ||||||

| Wood Street Mill | SJ 9175 7337 53°15′26″N 2°07′30″W[7] | ||||||

|

Notes: | ||||||

| [3][10] | |||||||

River Dean

Bollington

The Swindells family dominated cotton spinning in Bollington. They operated or owned Ingersley Vale Mill from 1821, Rainow Mill from 1822 both until 1841. They built the Clarence Mill with their partners the Brooke family in 1834, and extended it in 1841, 1854 and 1877. Thomas Oliver & Sons were at the Higher and Lower Mill from 1832 until 1859 and at the Waterhouse Mill from 1841. The Greg family from Quarry Bank Mill and later Reddish leased the Lower House Mill in 1832. The Swindells went on to build the Adelphi Mill in 1856.[11][12]

| Name | Architect | Location | Built | Demolished | Served (Years) | ||

|---|---|---|---|---|---|---|---|

| Adelphi Mill | SJ930773 53°17′35″N 2°06′22″W | ||||||

|

|

||||||

| Clarence Mill | Clarence Brow SJ934782 53°18′04″N 2°06′00″W | ||||||

|

|

||||||

| Defiance Mill | SJ9373 7798 53°17′55″N 2°05′44″W[13] | ||||||

| Notes: The mill stands and is now in residential use.[12] | |||||||

| Higher Mill | SJ939776 53°17′42″N 2°05′35″W | ||||||

| Lower Mill | SJ938777 53°17′46″N 2°05′38″W | ||||||

| Lowerhouse Mill | SJ922777 53°17′46″N 2°07′05″W[14] | 1818 | 203 | ||||

|

|||||||

| Oak Bank Print Works | SJ9380 7790 53°17′53″N 2°05′40″W[13] | ||||||

| Sowcar Mill | SJ9425 7803 53°17′57″N 2°05′16″W[13] | ||||||

| Turner Heath Mill | SJ928 768 53°17′17″N 2°06′32″W[13] | ||||||

| Waterhouse Mill | SJ9293 7785 53°17′51″N 2°06′27″W[13][15] | 1791 | 1962 | 169 | |||

| Notes: The Firm of "Thomas Oliver & Sons" began, in what was known as "The Bollington Mills" i.e. the "Higher Mill" formerly a Brewery, and the "Lower Mill" afterwards a paper mill. These were leased from Mr Harrop of Stockport, and Mr Creswick of Sheffield, both solicitors. Waterhouse Mill was built in 1790 by Peter Lomas, and acquired by the Olivers through marriage to Mary Lomas. It took water by a leat from the River Dean weir to a mill pond which drove a 23 ft waterwheel, the water passed through a sough (culvert) back into river at the Garden Street bridge.. The first mill burnt down in 1799 and was rebuilt in 1800 and enlarged in 1838. The mills started with jennies, then by 1799 were ordering mules with 216 spindles. The firm produced the finest cotton counts by 1860, they were spinning 220s, and by 1886 420s. In this year ring doubling was introduced. Power was initially by water but a supplementary beam engine was added- and these were replaced in 1906 by a Musgraves horizontal. In 1898 Thomas Oliver & Sons became a part of The Fine Spinners & Doublers Association which was set up to enable cotton mills to trade collectively and benefit from the increased scale. They owned the trademark Happy Valley, and during the First World War made fabric for aeroplane wings and before the second war the thread used for the sports clothes of the England Cricket Team during an Ashes tour to Australia. | |||||||

| [12][13][16] | |||||||

Rainow

| Name | Architect | Location | Built | Demolished | Served (Years) | ||

|---|---|---|---|---|---|---|---|

| Brookhouse Clough Mill | SJ 9476 7512[7] | ||||||

| Brookhouse Mill | SJ 9461 7523[7] | ||||||

| Cow Lane Mill | SJ 9457 7580[7] | ||||||

| Gin Clough Mill | SJ958764 53°17′06″N 2°03′50″W[17] | ||||||

|

|

||||||

| Hough Hole Mill | SJ944766 53°17′10″N 2°05′06″W[17] | ||||||

| Ingersley Vale Works | SJ942744 53°16′01″N 2°05′17″W[17] | ||||||

| Notes: A cotton spinning mill in 1792 was water powered. The lodge was enlarged, creating Clough Pool in 1803 by Edward Collier. This powered two waterwheels placed above each other. An 18hp steam engine was also present. The mill changed ownership in 1811 and was damaged by fire in 1819. The buildings on the site at this time included a spinning block,owner's house, a warehouse, a smithy and a apprentices house for paupers. The mill was rebuilt by August 1821 by Thomas Gaskell of Ingersley Hall who became a partner with Martin Swindells. By 1826, there were 330 power looms. The Swindells took full control of the site in 1830. In 1842 when James Leigh took over and cotton spinning ceased. The buildings were converted to printing calico, the wheelhouse was rebuilt and a single 56 feet (17 m) diameter wheel was installed, the second largest in Britain. By 1874, the mill had converted to a dyeworks. A J King ran a bleachworks between 1878 and 1929. The first floor of the spinning mill was removed and in 1895, the water wheel was converted to drive a dynamo and all the processes were powered by electric motors. In the later 20th century, the site was sold to Slater, Harrison & Co. and used as letterpress and litho printworks. A fire in November 1999 destroyed the roof and floors of the original mill building and it is currently under restoration.[19] | |||||||

| Ingersley Hall Mill ?? | |||||||

| Lowerhouse Mill | SJ 9538 7656[7] | ||||||

| Millbrook Mill | SJ 9489 7575[7] | ||||||

| Rainow Mill | SJ914775 53°17′38″N 2°07′48″W[7][17] | ||||||

|

Notes: Founded by Martin Swindells and John and Thomas Fernley in 1822. | ||||||

| Springbank Mill | SJ 9451 7518[7] | ||||||

| Tower Hill Mill | SJ946758 53°16′44″N 2°04′55″W[17] | ||||||

| Waulk Mill ?? | |||||||

| [7][17] | |||||||

River Dane

Congleton

Congleton had England's third oldest silk-throwing mill and spun both cotton and silk. Its prosperity depended on tariffs imposed on imported silk. When the tariffs were removed in the 1860s, the empty mills moved over to fustian cutting. A limited silk ribbon weaving industry survived into the 20th century, and woven labels were still being produced to the 1990s. Many mills survive, as industrial or units.[20]

| Name | Architect | Location | Built | Demolished | Served (Years) | ||

|---|---|---|---|---|---|---|---|

| Albany Mill | SJ8614625553°09′36″N 2°12′31″W[13] | ||||||

| Albert Mill | SJ8644630553°09′52″N 2°12′15″W[13] | standing | |||||

| Bank Mill | SJ8689634353°10′04″N 2°11′51″W[13] | standing | |||||

| Bath Vale Mill | SJ873633 53°10′01″N 2°11′28″W[21] | ||||||

| Notes: Conder & Company[22] | |||||||

| Booth Street Mill | SJ8543629553°09′49″N 2°13′10″W[13] | ||||||

| Booth Street Mill (2) | SJ8544629853°09′49″N 2°13′09″W[13] | ||||||

| Bridge Mill | SJ8578633153°10′00″N 2°12′51″W[13][20] | ||||||

|

Notes: Built for fustian, used later for paper, printed-circuit boards and a carpet warehouse. | ||||||

| Bridge Street Mill | SJ8578628753°09′46″N 2°12′51″W[13] | ||||||

| Bromley Road Mill | SJ8651630553°09′52″N 2°12′12″W[13] | ||||||

| Brook Mills | SJ8583631353°09′54″N 2°12′48″W[13][23] | ||||||

|

Notes: aka Solly's, BossunsReade and Company Silk Spinners. Brook Mill and the Stone House Green Mill formed a group on the Howty Brook approached the River Dane. They came into joint ownership in 1852 Brook Mill started as silk throwing and weaving site, Stone House Green Mill was used for short-silk and cotton spinning, but by 1853 they were used for long-silk spinning. [22][23] Bossun's used part of the mill to manufacture plaster cast figures. |

||||||

| Brookside Mill | SJ858632 53°09′58″N 2°12′50″W[13][21] | standing | |||||

|

Notes: See:Brook Mills | ||||||

| Canal Street Mill | SJ8652621253°09′22″N 2°12′11″W[3] | ||||||

| Cross Street Mill | SJ8573630853°09′53″N 2°12′54″W[3][20] | ||||||

| Notes: A silk throwing mill converted to fustian cutting then used as a cinema, and a garage. | |||||||

| Dane Mill | SJ 8540 6340 53°10′08″N 2°13′37″W[21] | ||||||

|

Notes: Bought by the Pearsons in 1830. | ||||||

| Dane Mill (Slate's) | SJ8565632153°09′57″N 2°12′58″W[3] | ||||||

| Danebridge Mill | SJ8586623853°09′30″N 2°12′46″W[3] | ||||||

Notes: Now demolished. The first mill was described in 1831:The second mill had a larger footprint but was only 3 storeys. The mill was from 1890, a fustian cutting mill, and remained so up to 1934. The mill, however, was also occupied by Condura, a subsidiary company of Conlowe Ltd a limited liability company in 1930 (Congleton Chronicle 1932). The company known for 'Judy Frocks' occupied part of the mill, and initially employed around thirty people which grew to 100 people. By 1958, Conlowe companies were subsidiaries of the English Sewing Cotton Company,[24] |

|||||||

| Daneside Mill | SJ8575632553°09′58″N 2°12′53″W[3][20] | 1910 | |||||

| Notes: Cotton, silk-throwing, silk-spinning and fustian cutting. | |||||||

| Dane Street Mill | SJ8535631253°09′54″N 2°13′14″W[3] | ||||||

| Dane Row Mills?? | SJ 896657 53°11′17″N 2°09′25″W[21] | ||||||

| Dane Valley Mill | SJ 86737 63802 53°10′16″N 2°11′59″W[25] | ||||||

| Dane in Shaw Mill | SJ883620 53°09′18″N 2°10′34″W[20][21] | 1784 | 237 | ||||

| Notes: aka Martin's Mill. Symmetrical eighteen bay four storey mill, with pediment over centre two bays, internal waterwheel, clock face in pediment. Mill lodge in front. Built to spin cotton after Arkwright's water frame patent lapsed. | |||||||

| Davenshaw Mill | Buglawton, SJ86606340 53°10′07″N 2°12′05″W[3] | ||||||

| Eaton Bank Mill | SJ86746386 53°10′18″N 2°11′59″W[3] | ||||||

| Edward Mill | SJ8646630553°09′52″N 2°12′14″W[3] | ||||||

| Elizabeth Mill | SJ8627630353°09′51″N 2°12′24″W[3] | ||||||

| Notes: See Victoria Mill | |||||||

| Fair Mill | Worrall Street SJ8597630853°09′53″N 2°12′41″W[3][20][26] | 1870 | Standing | 151 | |||

|

Notes: Used for Fustian in the 1890s, and then for cardboard box manufacture- now a Medical practice. This two-storey building was typical of a fustian mill 8m wide by 49m with a clear uncluttered floor. The boards were 100mm thick. The foof was supported by a king post. The windows are wide with segmented brick arches. | ||||||

| Flint Mill | Buglawton SJ8668637653°10′10″N 2°12′12″W[3] | ||||||

| Notes: See Higher Washford Mill | |||||||

| Forge Mill | SJ8490636053°10′09″N 2°13′38″W[3] | ||||||

| Notes: Run by Peter Wild until 1952 when the firm downsized and moved to Leek. | |||||||

| Foundry Mill | SJ862630 53°09′50″N 2°12′29″W[21] | ||||||

| Havannah St Mills | Eaton SJ 896657 53°11′17″N 2°09′25″W[3][21] | ||||||

|

Notes: | ||||||

| Highbank Mill | SJ8627628153°09′44″N 2°12′24″W[13] | ||||||

| Higher Washford Mill | Buglawton SJ 8642 6357 53°10′10″N 2°12′12″W[3][27][28] | standing | |||||

|

Notes: The central part, called the Flint Mill was built as a corn mill, then used as a silk mill (c 1828) before working commercially as a flint mill from c1864 until 1958. Dating from the late 18th century, and extended in early and mid nineteenth century, it contains with late 19th and earlier twentieth machinery that was driven by a breast shot cast-iron bucket waterwheel of 18 feet (5.5 m) diameter. Listed Building NGR: SJ8652563642 The power from the wheel was taken by shafts to the upper floors and to two adjacent textile mills. |

||||||

| Kinsey Street Mill | SJ8605630153°09′50″N 2°12′36″W[13] | ||||||

| Lower Park Street Mill | SJ8614630153°09′50″N 2°12′32″W[13] | ||||||

| Lower Spragg Street Mill | SJ8630630053°09′50″N 2°12′23″W[13] | ||||||

| Meadow Mill | SJ860631 53°09′54″N 2°12′40″W[20][21] | ||||||

| Notes: Built in 1864 for silk-throwing, Shephard's then used it for fustian cutting, then was used by Edgar Hallet & Co for making uniform braid. It is now residential. | |||||||

| Moody Street Mill | SJ8587626653°09′39″N 2°12′46″W[13] | ||||||

| Old Mill | SJ859632 53°10′00″N 2°12′42″W[20][21][29] | 1750 | 2003 | 246 | |||

_in_1902.png.webp) |

Notes: Old Mill was an early silk mill established in the 1753. It used an internal water wheel to power Italian silk throwing machines. It was notable for its size, and for the involvement of James Brindley in its construction. The mill was extended and a beam engine added c.1830, but it was partially demolished in 1939. When, in 2003 the remaining structures were demolished a full archaeological survey was done. 1822. Eleven circular throwing machines were housed on the ground floor with winding machines above.In 1771 it employed 600. This was extended by another 17 bays in 1830. The Pearsons bought the mill from the Patinsons in 1830. In 1935 it suffered from subsidence, and Roldane Mill was built for some of the equipment. In 1939, the top three storeys were removed. It continued in use until 1996. It was demolished in 2003. |

||||||

| Park Mill | SJ8625629653°09′49″N 2°12′26″W[13][30] | 1825 | 196 | ||||

|

Notes: Erected speculatively by 1825 by Charles Townley a builder. The design was the standard format at that time. It had 3 storeys with 15 bays. | ||||||

| Park Street Mill | SJ862629 53°09′47″N 2°12′29″W[21] | ||||||

| Pool Bank Mill | SJ891629 53°09′47″N 2°09′50″W[21] | ||||||

| Primrose Vale Mill | SJ8717624153°09′31″N 2°11′36″W[21] | ||||||

| Prospect Mill | SJ8521629153°09′47″N 2°13′22″W[21] | ||||||

| Providence Mill | SJ8577632253°09′57″N 2°12′51″W[20][21] | 1913 | standing | 67 | |||

|

Notes: Fustian cutting mill built in 1913, named because it had 13 steps and 13 windows but it would have tempted providence to change it. It was used later to manufacture children's clothing. It was used to print Bingo cards, became derelict in 2003 and has been converted to housing. | ||||||

| Riverside Mill | SJ8595631153°09′54″N 2°12′42″W[20] | ||||||

|

Notes: Built in 1890 for James Collinge, fustian cutter. In 1906 Ansiamio used it to manufacture cigars. Later from the 1950s, it was used for garment manufacture. | ||||||

| Roldane Mill | SJ8592634553°10′00″N 2°12′45″W[21] | ||||||

|

Notes: Built in 1934 adjacent to Old Mill for making up of knitted garments. The site is being developed for sheltered housing in 2012. | ||||||

| Royle Street Mill 1 | SJ85726327 53°10′05″N 2°12′54″W[20][21] | ||||||

|

Notes: 3 storey mill built by Thomas Vaudrey, used for silk and faustian. It was steam powered from 1826, and later reduced to two storeys and used as a snooker hall. | ||||||

| Royle Street Mill 2 | SJ85796335 53°10′05″N 2°12′54″W[21] | ||||||

| Salford Mill | Milk St SJ857634 53°10′05″N 2°12′54″W[20][21] | ||||||

|

|

||||||

| Shepherd Mills | SJ8608630853°09′53″N 2°12′35″W[13][20] | 1890 | 131 | ||||

|

Notes: aka Perseverance Mill. This was built as a fustian mill and was used for shirt manufacture between 1906 and 1959, and for pyjamas from 1960 to 1998. | ||||||

| Shop Lane Mill | SJ8650625053°09′34″N 2°12′12″W[13] | ||||||

| Silk Street Mill | SJ8549659553°11′25″N 2°13′07″W[13] | ||||||

| Silver Springs Mills | SJ89562753°09′40″N 2°09′29″W[13] | ||||||

| Spindle Street Mill | SJ8634629953°09′50″N 2°12′21″W[13] | ||||||

| Spragg Street Mill | SJ8632629553°09′49″N 2°12′22″W[13] | ||||||

| Stonehouse Green Mill | SJ8579 6301 53°09′50″N 2°12′50″W[13] | 1780s | |||||

| Notes: Brook Mill and the Stone House Green Mill formed a group on the Howty Brook approached the River Dane. They came into joint ownership in 1852 Brook Mill started as silk throwing and weaving site, Stone House Green Mill was built to spin cotton after Arkwright's water frame patent lapsed and was used for both short-silk and cotton spinning, but by 1853 they were used for long-silk spinning. See: Brook Mills | |||||||

| Sunnyside Mill | SJ8620625453°09′35″N 2°12′28″W[13] | ||||||

| Swan Bank Mill | SJ8541631153°09′54″N 2°13′11″W[13] | 1876 | |||||

| Notes: A stream driven mill employing 400. Destroyed in 1876 | |||||||

| Square Mill | SJ8591631153°09′54″N 2°12′44″W[13] | ||||||

| Thomas Street Mill | SJ8641 631153°09′54″N 2°12′17″W[13] | ||||||

| Throstles Nest Mill | SJ8664 635853°10′09″N 2°12′05″W[13] | ||||||

| Timbersbrook Mill | SJ896627 53°09′40″N 2°09′25″W[21] | ||||||

| Vale Mill | SJ8576 6270 53°09′40″N 2°12′52″W[13] | ||||||

| Victoria Mill | SJ8627 630353°09′51″N 2°12′24″W[13] | 1822 | standing | 165 | |||

|

Notes: Built by John Hall, a silk-throwster in 1822.Berisford started here in 1872. Run by Berisfords, along with the neighbouring Century Mill weaving sheds, Elizabeth Mill.In 1987 it was turned over to retail.[22] | ||||||

| Victoria Street Mill | SJ85862953°09′47″N 2°12′50″W[13] | ||||||

| Wallworth Bank Mill | SJ8632627353°09′41″N 2°12′22″W[3] | ||||||

| Washford Mill | SJ8642635753°10′09″N 2°12′17″W[3] | ||||||

| Westfield Mill | SJ8522628453°09′45″N 2°13′21″W[3] | ||||||

| Worrall Street Mill | SJ861631 53°09′54″N 2°12′32″W[21] | ||||||

| [21] | |||||||

Kettleshulme

| Name | Architect | Location | Built | Demolished | Served (Years) |

|---|---|---|---|---|---|

| Lumbhole Mill | SJ 9882 8038 53°19′13″N 2°01′09″W[3] | ||||

|

Notes: The mill was built in 1797 and heightened in 1815 then destroyed by fire in 1822 and rebuilt. It was powered by a cast-iron suspension 7.6m diameter by 1.7m water wheel working in conjunction with a beam engine. The current combination dates from c 1835, though a 10 hp engine was in place in 1816, when Lumbhole mill was being used for silk manufacture by George Brocklehurst. Later it converted to cotton and was known for the production of candlewick by the Sheldon family. The mill was four-storey, 30 yards (27 m) by 11 yards (10 m), it was built from Millstone Grit and had a Queen Post Truss roof | ||||

Knutsford

| Name | Architect | Location | Built | Demolished | Served (Years) |

|---|---|---|---|---|---|

| Silk Street Mill | SJ752 787 53.3047°N 2.3736°W[3] | ||||

Warrington

| Name | Architect | Location | Built | Demolished | Served (Years) |

|---|---|---|---|---|---|

| Cockhedge Mill | SJ609884 53°23′28″N 2°35′20″W | 1831 | 190 | ||

| Notes: Cockhedge Mill was a large combined mill (spinning, calico weaving and dying) owned by Armitage and Rigby Ltd (1888). The buildings were commenced in late 1831,[31] but a large fire on 18 June 1872 caused a rebuild. The article about the fire in the Illustrated London News,.[32] It was then a five-storey building employing 900 persons. The report said there were 14,000 throstle spindles and 21,000 mule spindles. The steam engine and 6,000 spindles were saved, and 420 people lost their jobs. | |||||

| Ashmore 1982, p. 66 | |||||

Prestbury

| Name | Architect | Location | Built | Demolished | Served (Years) |

|---|---|---|---|---|---|

| Butley Mill | SJ89977453°23′28″N 2°35′20″W[7] | ||||

See also

References

- Historic England (2011). "Quarry Bank Mill (1237687)". National Heritage List for England. Retrieved 2 May 2011.

- "Quarry Bank Mill history". Retrieved 25 September 2007.

- Calladine & Fricker 1993, p. 163

- Ashmore 1982, p. 44

- Calladine, Anthony; Fricker, Jean (Spring 1988). "Pickford Street: A Study of Macclesfield Textile Mills". Industrial Archaeology Review. Manley. 10 (2): 146–161. doi:10.1179/030907288786472324.

- Calladine & Fricker 1993, pp. 49–50

- Calladine & Fricker 1993, p. 164

- Calladine & Fricker 1993, pp. 11,25

- Heritage Explorere

- Macclesfield Mill Photos

- Calladine & Fricker 1993, p. 107

- http://happy-valley.org.uk/history/historian_author.htm

- Calladine & Fricker 1993, p. 162

- A short history of Bollington Archived 28 March 2012 at the Wayback Machine Ken Edwards, April 2005

- Compiled by Revd. A. C. Oliver (1940). "Thomas Oliver & Sons (Bollington) Ltd". One hundred and fifty years of Fine Cotton Spinning. Retrieved 23 May 2012.

- Ashmore 1982, p. 30

- Ashmore 1982, p. 57

- Calladine & Fricker 1993, pp. 36,46

- Happy Valley Heritage Centre

- Fustian Mills Talk Archived 3 April 2015 at the Wayback Machine Lyndon Murgatroyd 2007

- Ashmore 1982, pp. 35,38

- Stephens 1970, p. 147

- National Archives

- Dane Bridge Mill Lyndon Murgatroyd

- Textile company

- Calladine & Fricker 1993, p. 105

- Calladine & Fricker 1993, p. 98

- http://www.britishlistedbuildings.co.uk/en-55948-flint-mill-central-part-of-higher-washfor

- Calladine & Fricker 1993, p. 84

- Calladine & Fricker 1993, p. 45,66

- Ashmore 1982, p. 66

- Cockhedge Mill Fire Wood engraving 1872

Bibliography

- Ashmore, Owen (1982). The industrial archaeology of North-west England. Manchester University Press. ISBN 0-7190-0820-4.

- Calladine, Anthony; Fricker, Jean (1993). East Cheshire Textile Mills. London: Royal Commission on Historical Monuments of England. ISBN 1-873592-13-2.

- Stephens, W. B. (1970). History of Congleton: Published to Celebrate the 700th Anniversary of the Granting of the Charter to the Town. Manchester University Press. ISBN 0-7190-1245-7.

External links

Media related to Textile mills in Cheshire at Wikimedia Commons

Media related to Textile mills in Cheshire at Wikimedia Commons