Pratt & Whitney JT9D

The Pratt & Whitney JT9D engine was the first high bypass ratio jet engine to power a wide-body airliner. Its initial application was the Boeing 747-100, the original "Jumbo Jet". It was Pratt & Whitney's first high-bypass-ratio turbofan.[2]

| JT9D | |

|---|---|

| |

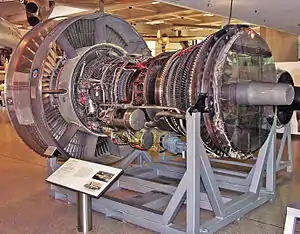

| The internal structure of the JT9D | |

| Type | Turbofan |

| National origin | United States |

| Manufacturer | Pratt & Whitney |

| First run | December 1966 |

| Major applications | Airbus A300/A310 Boeing 747 Boeing 767 McDonnell Douglas DC-10 |

| Number built | more than 3,200[1] |

| Developed into | Pratt & Whitney PW4000 |

Development

The JT9D program was launched in September 1965 and the first engine was tested in December 1966. It received its FAA certification in May 1969 and entered service in January 1970 on the Boeing 747. It subsequently powered the Boeing 767, Airbus A300 and A310, and Douglas DC-10. The enhanced JT9D-7R4 was introduced in September 1982 and was approved for 180-minute ETOPS for twinjets in June 1985. By 2020, the JT9D has flown more than 169 million total hours. Production ceased in 1990,[3] to be replaced by the upgraded PW4000.

The JT9D was developed as part of the design of the C-5 Galaxy. A contract was awarded to Pratt & Whitney to study the type of large engine needed, but the production contract was eventually awarded to the General Electric TF39. The engine's first test run took place in a test rig at East Hartford, Connecticut, with the engine's first flight in June 1968 mounted on a Boeing B-52E which served as a 747 testbed.

In 1968, its unit cost was $800,000,[4]

$5.9 million today.

Design

Advanced technologies in structures, aerodynamics, and materials improve fuel efficiency and reliability.[3] The JT9D was built using titanium alloys and nickel alloys. The engine featured a single-stage fan, a three-stage low-pressure compressor, and an eleven-stage high-pressure compressor coupled to a two-stage high-pressure turbine and four-stage low-pressure turbine. The JT9D-3, the earliest certified version of the engine, weighed 8,608 lb (3,905 kg) and produced 43,500 lbf (193 kN) thrust.

Pratt & Whitney faced difficulties with the JT9D design during the Boeing 747 test program. Engine failures during the flight test program resulted in thirty aircraft being parked outside the factory with concrete blocks hanging from the pylons, awaiting redesigned engines. Boeing and Pratt & Whitney worked together in 1969 to solve the problem. The trouble was traced to ovalization, in which stresses during takeoff caused the engine casing to deform into an oval shape and cause the high-pressure turbine blades to grind against the sides. This was solved by strengthening the engine casing and adding yoke-shaped thrust links.

JT9D engines powering USAF Boeing E-4A airborne command posts were designated F105.

Variants

All variants are dual axial turbofans with annular combustion chambers and 6 turbine stages.[5][6]

| Comp. | Model | Certification | Takeoff, dry | Length | Width | Weight | LP rpm | HP rpm | T/W | Fan[lower-alpha 1] | Application |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 15-stage[5] | JT9D-3A | Jan 9, 1970 | 43,500 lbf (193 kN) | 154.89 in 3.934 m |

95.60 in 2.428 m |

8,713 lb (3.952 t) | 3650 | 7850 | 4.99 | 92.3 in 2.34 m |

B747[7] |

| JT9D-7 | Jun 14, 1971 | 45,500 lbf (202 kN) | 8,880 lb (4.03 t) | 3750 | 8000 | 5.12 | |||||

| JT9D-7A | Sep 22, 1972 | 46,150 lbf (205.3 kN) | 5.2 | ||||||||

| JT9D-20 | Oct 16, 1972 | 44,500 lbf (198 kN) | 8,470 lb (3.84 t) | 3650 | 5.25 | DC-10[8] | |||||

| JT9D-7H | Jun 19, 1974 | 45,500 lbf (202 kN) | 8,880 lb (4.03 t) | 5.12 | B747[7] | ||||||

| JT9D-7AH | 46,150 lbf (205.3 kN) | 5.2 | |||||||||

| JT9D-7F | Sep 30, 1974 | 46,750 lbf (208.0 kN) | 3750 | 5.26 | |||||||

| JT9D-7J | Aug 31, 1976 | 48,650 lbf (216.4 kN) | 5.48 | ||||||||

| JT9D-20J | Dec 29, 1986 | 48,050 lbf (213.7 kN) | 8,580 lb (3.89 t) | 5.6 | DC-10[8] | ||||||

| 16-stage[6] | JT9D-59A | Dec 12, 1974 | 51,720 lbf (230.1 kN) | 154.256 in 3.9181 m |

97.03 in 2.465 m |

9,140 lb (4.15 t) | 3780 | 8011 | 5.66 | 93.6 in 2.38 m |

DC-10[8] A300[9] |

| JT9D-70A | 51,140 lbf (227.5 kN) | 9,155 lb (4.153 t) | 5.59 | B747[7] | |||||||

| JT9D-7Q | Oct 31, 1978 | 51,900 lbf (231 kN) | 9,295 lb (4.216 t) | 3888 | 8000 | 5.58 | |||||

| JT9D-7Q3 | Oct 22, 1979 | 3960 | 5.58 | ||||||||

| JT9D-7R4D | Nov 25, 1980 | 48,000 lbf (210 kN) | 96.00 in 2.438 m |

8,935 lb (4.053 t) | 3770 | 5.37 | 93.4 in 2.37 m |

B767[10] | |||

| JT9D-7R4D1 | Apr 1, 1981 | 8,915 lb (4.044 t) | 3810 | 5.38 | A310[9] | ||||||

| JT9D-7R4E | 50,000 lbf (220 kN) | 3770 | 5.61 | B767[10] | |||||||

| JT9D-7R4E1 | 154.295 in 3.9191 m |

8,935 lb (4.053 t) | 3810 | 5.6 | A310[9] | ||||||

| JT9D-7R4G2 | Jul 23, 1982 | 54,750 lbf (243.5 kN) | 9,170 lb (4.16 t) | 3825 | 8080 | 5.97 | B747[7] | ||||

| JT9D-7R4H1 | 56,000 lbf (250 kN) | 8,915 lb (4.044 t) | 3810 | 6.28 | A300-600[9] | ||||||

| JT9D-7R4E4 | Mar 29, 1985 | 50,000 lbf (220 kN) | 8,935 lb (4.053 t) | 5.6 | B767[10] |

Applications

- Airbus A300

- Airbus A310

- Boeing 747-100/200/300/SP

- Boeing 767 (early models)

- Boeing RC-1

- McDonnell Douglas DC-10-40

Specifications (JT9D-7R4)

Data from Pratt & Whitney[3]

General characteristics

- Type: High bypass turbofan

- Length: 132.7 in (3.37 m) (flange to flange)

- Diameter: 93.4 in (2.37 m) (fan tip)

- Dry weight:

Components

- Compressor:

Performance

- Maximum thrust: 48,000–56,000 lbf (214–249 kN) takeoff (flat rated at 86 °F (30 °C))

- Overall pressure ratio: overall 26.7 (fan 1.67:1)

- Bypass ratio: 4.8:1

- Specific fuel consumption: ca 0.6 lb/lbf/h (17 g/kN/s) at M0.8 and 35,000–45,000 ft (11,000–14,000 m)[11]

- Power-to-weight ratio:

See also

Related development

Comparable engines

Related lists

References

- "Commercial Engines / JT9D". Pratt & Whitney.

- Gunston, Bill. World Encyclopedia of Aero Engines. Cambridge, England. Patrick Stephens Limited, 1989. ISBN 1-85260-163-9, p.126.

- "JT9D" (PDF). Pratt & Whitney.

- Aero Engines 1968, Flight International, 4 January 1968.

- "Type Certificate data sheet Number E20EA" (PDF). FAA. February 10, 2000.

- "Type Certificate data sheet Number E3NE" (PDF). FAA. July 25, 2019.

- "Type Certificate Data Sheet NO. A20WE" (PDF). FAA. February 27, 2015.

- "Type Certificate Data Sheet A22WE" (PDF). FAA. April 30, 2018.

- "Type certificate data sheet A.172 for Airbus A300, A310 and A300-600" (PDF). EASA. 11 March 2019.

- "Type Certificate Data Sheet No. A1NM" (PDF). June 20, 2016. Archived from the original (PDF) on September 29, 2018. Retrieved March 26, 2020.

- "D: Thrust Data for Performance Calculations". Thrust Data for Performance Calculations. Figure D9. 2006. pp. 267–276. doi:10.1002/9780470117859.app4. ISBN 9780470117859.CS1 maint: location (link)