Prince Rupert's drop

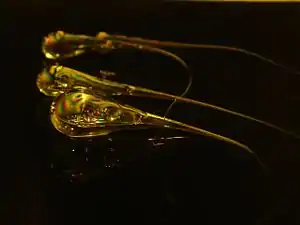

Prince Rupert's drops (also known as Dutch or Batavian tears)[1][2] are toughened glass beads created by dripping molten glass into cold water, which causes it to solidify into a tadpole-shaped droplet with a long, thin tail. These droplets are characterized internally by very high residual stresses, which give rise to counter-intuitive properties, such as the ability to withstand a blow from a hammer or a bullet on the bulbous end without breaking, while exhibiting explosive disintegration if the tail end is even slightly damaged. In nature, similar structures are produced under certain conditions in volcanic lava, and are known as Pele's tears.

The drops are named after Prince Rupert of the Rhine, who brought them to England in 1660, although they were reportedly being produced in the Netherlands earlier in the 17th century and had probably been known to glassmakers for much longer. They were studied as scientific curiosities by the Royal Society and the unravelling of the principles of their unusual properties probably led to the development of the process for the production of toughened glass, patented in 1874. Research carried out in the 20th and 21st centuries shed further light on the reasons for the drops' contradictory properties.

Description

Prince Rupert's drops are produced by dropping molten glass drops into cold water. The water rapidly cools and solidifies the glass from the outside inward. This thermal quenching may be described using a simplified model of a rapidly cooled sphere.[3] Prince Rupert's drops have remained a scientific curiosity for nearly 400 years due to two unusual mechanical properties:[4] when the tail is snipped, the drop disintegrates explosively into powder, whereas the bulbous head can withstand compressive forces of up to 15,000 newtons (3,400 lbf).[2]

The explosive disintegration arises due to multiple crack bifurcation events when the tail is cut – a single crack is accelerated in the tensile residual stress field in the center of the tail and bifurcates after it reaches a critical velocity of 1,450–1,900 metres per second (3,200–4,300 mph).[5][6] Given these high speeds, the disintegration process due to crack bifurcation can only be inferred by looking into the tail and employing high speed imaging techniques. This is perhaps why this curious property of the drops remained unexplained for centuries.[7]

The second unusual property of the drops, namely the strength of the heads, is a direct consequence of large compressive residual stresses—up to 700 megapascals (100,000 psi)—that exist in the vicinity of the head's outer surface.[2] This stress distribution is measured by using glass's natural property of stress-induced birefringence and by employing techniques of 3D photoelasticity. The high fracture toughness due to residual compressive stresses makes Prince Rupert's drops one of the earliest examples of toughened glass.

History

A scholarly account of the early history of Prince Rupert's drops is given in the Notes and Records of the Royal Society of London. Most of the early scientific study of the drops was performed at the Royal Society.[8]

The drops are reliably reported to have been made in Mecklenburg in North Germany, as early as 1625.[9] However, it has been claimed that they were invented in the Netherlands (although it has been suggested that they had been known about by glassmakers since the time of the Roman Empire),[8] hence common names for them in the 17th century were lacrymae Borussicae (Prussian tears) or lacrymae Batavicae (Dutch tears).[10] The secret of how to make them remained in the Mecklenburg area for some time, although the drops were disseminated across Europe from there, for sale as toys or curiosities.

The Dutch scientist Constantijn Huygens asked Margaret Cavendish, Duchess of Newcastle to investigate the properties of the drops; her opinion after carrying out experiments was that a small amount of volatile liquid was trapped inside.[11]

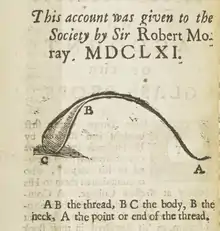

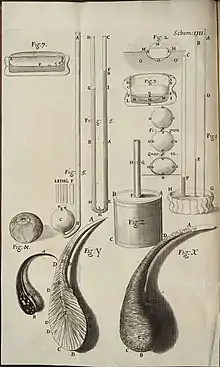

Although Prince Rupert did not discover the drops, he played a role in their history by bringing them to Britain in 1660. He gave them to King Charles II, who in turn delivered them in 1661 to the Royal Society (which had been created the previous year) for scientific study. Several early publications from the Royal Society give accounts of the drops and describe experiments performed.[12] Among these publications was Micrographia of 1665 by Robert Hooke, who later would discover Hooke's Law.[4] His publication laid out correctly most of what can be said about Prince Rupert's drops without a fuller understanding than existed at the time, of elasticity (to which Hooke himself later contributed) and of the failure of brittle materials from the propagation of cracks. A fuller understanding of crack propagation had to wait until the work of A. A. Griffith in 1920.[13]

In 1994, Srinivasan Chandrasekar, an engineering professor at Purdue University, and Munawar Chaudhri, head of the materials group at the University of Cambridge, used high-speed framing photography to observe the drop-shattering process and concluded that while the surface of the drops experiences highly compressive stresses, the inside experiences high tension forces, creating a state of unequal equilibrium which can easily be disturbed by breaking the tail. However, this left the question of how the stresses are distributed throughout a Prince Rupert's drop.

In a further study published in 2017, the team collaborated with Hillar Aben, a professor at Tallinn University of Technology in Estonia using a transmission polariscope to measure the optical retardation of light from a red LED as it travelled through the glass drop, and used the data to construct the stress distribution throughout the drop. This showed that the heads of the drops have a much higher surface compressive stress than previously thought at up to 700 megapascals (100,000 psi), but that this surface compressive layer is also thin, only about 10% of the diameter of the head of a drop. This gives the surface a high fracture strength which means that it is necessary to create a crack that enters the interior tension zone in order to break the droplet. As cracks on the surface tend to grow parallel to the surface, they cannot enter the tension zone but a disturbance in the tail allows cracks to enter the tension zone.[14]

Scientific uses

The process for the production of toughened glass by quenching was probably inspired by the study of the drops, as it was patented in England by Parisian Francois Barthelemy Alfred Royer de la Bastie, in 1874, just one year after V. De Luynes had published accounts of his experiments with them.[8]

It has been known since at least the 19th century that formations similar to Prince Rupert's drops are produced under certain conditions in volcanic lava.[15] More recently researchers at the University of Bristol and the University of Iceland have studied the glass particles produced by explosive fragmentation of Prince Rupert's drops in the laboratory to better understand magma fragmentation and ash formation driven by stored thermal stresses in active volcanoes.[16]

Literary references

Because of their use as a party piece, Prince Rupert's drops became widely known in the late 17th century—far more than today. It can be seen that educated people (or those in "society") were expected to be familiar with them, from their use in the literature of the day. Samuel Butler used them as a metaphor in his poem Hudibras in 1663,[17][18] and Pepys refers to them in his diary.[19]

The drops were immortalized in a verse of the anonymous Ballad of Gresham College (1663):

And that which makes their Fame ring louder,

With much adoe they shew'd the King

To make glasse Buttons turn to powder,

If off the[m] their tayles you doe but wring.

How this was donne by soe small Force

Did cost the Colledg a Month's discourse.[20]

Diarist George Templeton Strong wrote (volume 4, p. 122) of a hazardous sudden breaking up of pedestrian-bearing ice in New York City's East River during the winter of 1867 that "The ice flashed into fragments all at once like a Prince Rupert's drop."

Alfred Jarry's 1902 novel Supermale makes reference to the drops in an analogy for the molten glass drops falling from a failed device meant to pass eleven thousand volts of electricity through the supermale's body.

Sigmund Freud, discussing the dissolution of military groups in Group Psychology and the Analysis of the Ego (1921), notes the panic that results from the loss of the leader: "The group vanishes in dust, like a Prince Rupert's drop when its tail is broken off."

E. R. Eddison's 1935 novel Mistress of Mistresses references Rupert's drops in the last chapter as Fiorinda sets off a whole set of them.

In the 1940 detective novel There Came Both Mist and Snow by Michael Innes (J. I. M. Stewart), a character incorrectly refers to them as "Verona drops"; the error is corrected towards the end of the novel by the detective Sir John Appleby.

In his 1943 novella Conjure Wife, Fritz Leiber uses Prince Rupert drops as a metaphor for the volatility of several characters' personalities. These small-town college faculty people seem to be placid and impervious, but "explode" at a mere "flick of the filament".

Peter Carey devotes a chapter to the drops in his 1988 novel Oscar and Lucinda.

See also

| Wikisource has original text related to this article: |

Further reading

- Albergotti, Clifton (1989). "Prince Rupert's drops in literature". The Physics Teacher. 27 (7): 530–2. Bibcode:1989PhTea..27..530A. doi:10.1119/1.2342858.

- Sir Robert Moray (1661). "An Account of the Glass Drops", Royal Society (transcribed, archive reference).

External links

- . Popular Science Monthly. Vol. 8. January 1876. ISSN 0161-7370 – via Wikisource.

- PrinceRupertsDrop.com High-speed slow motion video demonstrations.

- Video showing the making and the breaking of Prince Rupert's Drops from the Museum of Glass

- Popular Science article with video detailing Prince Rupert's Drops

- Corning Inc. "The Glass Age, Part 2: Strong, Durable Glass". Youtube. Retrieved 2015-03-24. Former Mythbusters Adam Savage and Jamie Hyneman demonstrate Rupert's Drops, including diagram of internal stresses

References

- Guillemin, Amédée (1873). The Forces of Nature: A Popular Introduction to the Study of Physical Phenomena. MacMillan & Co. p. 435.

- Aben, H.; Anton, J.; Õis, M.; Viswanathan, K.; Chandrasekar, S.; Chaudhri, M. M. (2016). "On the extraordinary strength of Prince Rupert's drops". Appl. Phys. Lett. 109 (23): 231903. Bibcode:2016ApPhL.109w1903A. doi:10.1063/1.4971339.

- Narayanaswamy, O. S.; Gardon, Robert (1998). "Tempering glass spheres and related topics". Glass Science and Technology. 71: 120–128. Archived from the original on 2017-07-28. Retrieved 2017-05-09.

- Robert Hooke, Micrographia or Some Physiological Descriptions of Minute Bodies made by Magnifying Glasses with Observation and Inquiries thereupon (London, 1665), "Observation vii. of some Phaenomena of Glass Drops," Archived 2016-11-07 at the Wayback Machine pp. 33–44.

- Chandrasekar, S; Chaudhri, M. M. (1994). "The explosive disintegration of Prince Rupert's drops". Philosophical Magazine B. 70 (6): 1195–1218. Bibcode:1994PMagB..70.1195C. doi:10.1080/01418639408240284.

- Chaudhri, M. M. (1998). "Crack bifurcation in disintegrating Prince Rupert's drops". Philosophical Magazine Letters. 78 (2): 153–158. Bibcode:1998PMagL..78..153C. doi:10.1080/095008398178147.

- Davis, Edward Arthur (1999). Science In The Making. Great Britain: Taylor & Francis. pp. 1994 B70. ISBN 0-7484-07677.

- Brodsley, Laurel; Frank, Charles; Steeds, John W. (October 1986). "Prince Rupert's Drops". Notes and Records of the Royal Society of London. 41 (1): 1–26. doi:10.1098/rsnr.1986.0001. JSTOR 531493. S2CID 143527832.

- Beckmann, Johann; Francis, William; Griffith, J. W. (1846). "Prince Rupert's Drops – Lacrymae Vitreae". A History of Inventions, Discoveries, and Origins, Volume II (4th ed.). pp. 241–245. Archived from the original on 2017-01-02.

- Claud, Nic. le Cat (1756). "The Lacrymae Batavicae, or glass-drops, the tempering of steel, and effervescence, accounted for by the same principle". Philosophical Transactions. Royal Society. 10 (2): 560–566. Archived from the original on 2017-01-02.

- Akkerman, Nadine; Corporaal, Marguérite (19 May 2004). "Mad Science Beyond Flattery: The Correspondence of Margaret Cavendish and Constantijn Huygens". Early Modern Literary Studies. Retrieved 13 July 2019.CS1 maint: multiple names: authors list (link)

- See also: Neri, Antonio with Christopher Merret, trans., The art of glass wherein are shown the wayes to make and colour glass, pastes, enamels, lakes, and other curiosities / written in Italian by Antonio Neri; and translated into English, with some observations on the author; whereunto is added an account of the glass drops made by the Royal Society, meeting at Gresham College (London, England: Printed by A.W. for Octavian Pulleyn, 1662), An Account of the Glass Drops, pp. 353–362.

- Griffith, A. A. (1921). "The Phenomena of Rupture and Flow in Solids". Philosophical Transactions of the Royal Society of London. Series A, Containing Papers of a Mathematical or Physical Character. 221 (582–593): 163–98. Bibcode:1921RSPTA.221..163G. doi:10.1098/rsta.1921.0006. JSTOR 91192.

- Zyga, Lisa (9 May 2017). "Scientists solve 400-year-old mystery of Prince Rupert's drops". phys.org. Science X network. Archived from the original on 16 May 2017. Retrieved 16 May 2017.

- Goodrich, Joseph (1829). "Real and supposed effect of igneous action". The American Journal of Science and Arts. 16: 349. Archived from the original on 3 November 2017. Retrieved 27 September 2014.

- Cashman, Katharine; Nicholson, Emma; Rust, Alison; Gislason, Sigurdur (2010-08-05). "Breaking magma: Controls on magma fragmentation and ash formation" (PDF). Archived (PDF) from the original on 6 October 2014. Retrieved 27 September 2014.

- Butler, S., Hudibras (Zachary Grey edition, London, 1799), vol. 1, p. 390, lines 385–389; and see footnote p. 391.

- John Wilders edition (Oxford University Press, 1967)

- Pepys, S.: "The Diary" (ed. Robert Latham & William Matthews), vol. III (Berkeley and Los Angeles, University of California Press, 1970-76), 13 January 1662, p. 9.

- Stimson, Dorothy (July 1932). "Ballad of Gresham Colledge". Isis. 18 (1): 103–17. doi:10.1086/346689. JSTOR 224481. S2CID 143882964.