S-IC

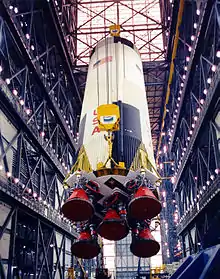

The S-IC (pronounced S-one-C[1][2]) was the first stage of the American Saturn V rocket. The S-IC stage was manufactured by the Boeing Company. Like the first stages of most rockets, most of its mass of more than 2,000 t (4,400,000 lb) at launch was propellant, in this case RP-1 rocket fuel and liquid oxygen (LOX) oxidizer. It was 42 m (138 ft) tall and 10 m (33 ft) in diameter, and provided 33,000 kN (7,500,000 lbf) of thrust to get the rocket through the first 61 km (38 mi) of ascent. The stage had five F-1 engines in a quincunx arrangement. The center engine was fixed in position, while the four outer engines could be hydraulically gimballed to control the rocket.

| |

| Manufacturer | Boeing |

|---|---|

| Country of origin | United States |

| Used on | Saturn V |

| General characteristics | |

| Height | 42 m (138 ft) |

| Diameter | 10 m (33 ft) |

| Gross mass | 2,280,000 kg (5,030,000 lb) |

| Empty mass | 290,000 lb (130,000 kg) |

| Launch history | |

| Status | Retired |

| Total launches | 13 |

| Successes (stage only) | 13 |

| First flight | November 9, 1967 (Apollo 4) |

| Last flight | May 14, 1973 (Skylab 1) |

| Engine details | |

| Engines | 5 F-1 |

| Thrust | 33,000 kN (7,500,000 lbf) |

| Specific impulse | 263 seconds (2.58 km/s) |

| Burn time | 150 s |

| Fuel | RP-1/LOX |

Manufacturing

The Boeing Co. was awarded the contract to manufacture the S-IC on December 15, 1961. By this time the general design of the stage had been decided on by the engineers at the Marshall Space Flight Center (MSFC). The main place of manufacture was the Michoud Assembly Facility, New Orleans. Wind tunnel testing took place in Seattle and the machining of the tools needed to build the stages at Wichita, Kansas.

MSFC built the first three test stages (S-IC-T, the S-IC-S, and the S-IC-F) and the first two flight models (S-IC-1 and -2). They were built using tools produced in Wichita.

It took roughly seven to nine months to build the tanks and 14 months to complete a stage. The first stage built by Boeing was S-IC-D, a test model.

Components

The largest and heaviest single component of the S-IC was the thrust structure, with a mass of 21 t (46,000 lb). It was designed to support the thrust of the five engines and redistribute it evenly across the base of the rocket. There were four anchors which held down the rocket as it built thrust. These were among the largest aluminum forgings produced in the U.S. at the time, 4.3 m (14 ft) long and 816 kg (1,799 lb) in weight. The four stabilizing fins withstood a temperature of 1,100 °C (2,010 °F).

Above the thrust structure was the fuel tank, containing 770,000 L (770 m3; 27,000 cu ft) of RP-1 fuel. The tank itself had a mass of 11 t (24,000 lb) dry and could release 7,300 L/s (7.3 m3/s; 260 cu ft/s). Nitrogen was bubbled through the tank before launch to keep the fuel mixed. During flight the fuel was pressurized using helium, which was stored in tanks in the liquid oxygen tank above.

Between the fuel and liquid oxygen tanks was the intertank.

The liquid oxygen tank held 1,305,000 L (1,305 m3; 46,100 cu ft) of LOX. It raised special issues for the designer. The lines through which the LOX ran to the engine had to be straight and therefore had to pass through the fuel tank. This meant insulating these lines inside a tunnel to stop fuel freezing to the outside and also meant five extra holes in the top of the fuel tank.

Two solid motor retrorockets were located inside each of the four conical engine fairings. At separation of the S-IC from the flight vehicle, the eight retrorockets fired, blowing off removable sections of the fairings forward of the fins, and backing the S-IC away from the flight vehicle as the engines on the S-II stage were ignited.

It also carried the ODOP transponder to track the flight after takeoff.

Cutaway diagram of the S-IC.

Cutaway diagram of the S-IC. Saturn V first stages S-1C-10, S-1C-11, and S-1C-9 at Michoud Assembly Facility.

Saturn V first stages S-1C-10, S-1C-11, and S-1C-9 at Michoud Assembly Facility. Apollo 11 S-IC separation.

Apollo 11 S-IC separation.

Stages built

| Serial number | Use | Launch date | Current location | Notes |

|---|---|---|---|---|

| S-IC-T | Static test firing | Part of Saturn V display at Kennedy Space Center.[3] | ||

| S-IC-S | Structural load testing (had no engines). | Location unknown (last seen at MSFC). | ||

| S-IC-F | Facilities testing for checking out launch complex assembly buildings and launch equipment. | Location unknown. | ||

| S-IC-D | Ground test dynamics model | U.S. Space & Rocket Center, Huntsville, Alabama 34°42′38.7″N 86°39′24.2″W |

||

| S-IC-1 | Apollo 4 | November 9, 1967 | Manufactured by MSFC. | |

| S-IC-2 | Apollo 6 | April 4, 1968 | Manufactured by MSFC; carried TV and cameras on boattail and forward skirt. | |

| S-IC-3 | Apollo 8 | December 21, 1968 | 30°12′N 74°7′W | Manufactured by Boeing (as with all subsequent stages); weighed less than previously manufactured units allowing 36 kg more payload. |

| S-IC-4 | Apollo 9 | March 3, 1969 | 30°11′N 74°14′W | |

| S-IC-5 | Apollo 10 | May 18, 1969 | 30°11′N 74°12′W | Last flight for S-IC R&D Instrumentation. |

| S-IC-6 | Apollo 11 | July 16, 1969 | 30°13′N 74°2′W | One or more engines recovered by a team financed by Jeff Bezos. |

| S-IC-7 | Apollo 12 | November 14, 1969 | 30°16′N 74°54′W | |

| S-IC-8 | Apollo 13 | April 11, 1970 | 30°11′N 74°4′W | |

| S-IC-9 | Apollo 14 | January 31, 1971 | 29°50′N 74°3′W | |

| S-IC-10 | Apollo 15 | July 26, 1971 | 29°42′N 73°39′W | |

| S-IC-11 | Apollo 16 | April 16, 1972 | 30°12′N 74°9′W | |

| S-IC-12 | Apollo 17 | December 7, 1972 | 28°13′N 73°53′W | |

| S-IC-13 | Skylab 1 | May 14, 1973 | Engine shutoff changed to 1-2-2 from 1–4 to lessen loads on Apollo Telescope Mount. | |

| S-IC-14 | Unused | Saturn V display at Johnson Space Center. | Scheduled for Apollo 18/19. | |

| S-IC-15 | Unused | On display at Michoud Assembly Facility until June 2016 then preserved at INFINITY Space Center in Mississippi. | Designated but never used as a backup Skylab launch vehicle. | |

See also

References

- Murray, Charles A.; Cox, Catherine Bly (Jul 1989). Apollo, the race to the moon. Simon and Schuster. p. 54. ISBN 9780671611019.

- Woods, W. David (2011-08-08). How Apollo Flew to the Moon. Springer Science & Business Media. p. 24. ISBN 9781441971791.

- Casebolt, Barry J. (1974-03-18). "Headed for Florida Museum - Veteran Moon Rocket Booster Leaves MSFC". The Huntsville (Alabama, USA) Times.

External links

| Wikimedia Commons has media related to Saturn S-IC. |