Soundproofing

Soundproofing is any means of reducing the sound pressure with respect to a specified sound source and receptor. There are several basic approaches to reducing sound: increasing the distance between source and receiver, using noise barriers to reflect or absorb the energy of the sound waves, using damping structures such as sound baffles, or using active antinoise sound generators.[1][2]

There are 5 elements in sound reduction (Absorption, Damping, Decoupling, Distance, and Adding Mass). The "Absorption" aspect in soundproofing should not be confused with Sound Absorbing Panels used in acoustic treatments. "Absorption" in this sense only refers to reducing a resonating frequency in a cavity by installing insulation between walls, ceilings or floors. Acoustic Panels can play a role in a treatment only after walls or ceilings have been soundproofed, reducing the amplified reflection in the source room.

Two distinct soundproofing problems may need to be considered when designing acoustic treatments—to improve the sound within a room (see reverberation), and reduce sound leakage to/from adjacent rooms or outdoors (see sound transmission class and sound reduction index). Acoustic quieting and noise control can be used to limit unwanted noise. Soundproofing can suppress unwanted indirect sound waves such as reflections that cause echoes and resonances that cause reverberation. Soundproofing can reduce the transmission of unwanted direct sound waves from the source to an involuntary listener through the use of distance and intervening objects in the sound path.

Absorption

Sound absorbing material controls reverberant sound pressure levels within a cavity, enclosure or room. Synthetic Absorption materials are porous, referring to open cell foam (acoustic foam, soundproof foam). Fibrous absorption material such as cellulose, mineral wool, fiberglass, sheep’s wool, are more commonly used to deaden resonant frequencies within a cavity (wall, floor, or ceiling insulation), serving a dual purpose for their thermal insulation properties. Both fibrous and porous absorption material are used to create acoustic panels, which absorb sound reflection in a room, improving speech intelligibility.[3][4]

Porous absorbers

Porous absorbers, typically open cell rubber foams or melamine sponges, absorb noise by friction within the cell structure.[5] Porous open cell foams are highly effective noise absorbers across a broad range of medium-high frequencies. Performance can be less impressive at lower frequencies.

The exact absorption profile of a porous open-cell foam will be determined by a number of factors including the following:

- Cell size

- Tortuosity

- Porosity

- Material thickness

- Material density

Resonant absorbers

Resonant panels, Helmholtz resonators and other resonant absorbers work by damping a sound wave as they reflect it.[6] Unlike porous absorbers, resonant absorbers are most effective at low-medium frequencies and the absorption of resonant absorbers is always matched to a narrow frequency range.

Damping

Damping means to reduce resonance in the room, by absorption or redirection (reflection or diffusion). Absorption will reduce the overall sound level, whereas redirection makes unwanted sound harmless or even beneficial by reducing coherence. Damping can reduce the acoustic resonance in the air, or mechanical resonance in the structure of the room itself or things in the room.

Decoupling

Creating separation between a sound source and any form of adjoining mass, hindering the direct pathway for sound transfer.

Decoupling a wall involves the use of Resilient Isolation Clips or Sound Damping Pads. The clips should be staggered when installed (every other stud) to create fewer pathways for sound to transfer. The Resilient Isolation Channel easily clicks into the Resilient Clips, resulting in a 1 5/8” gap between the stud and drywall. Fine thread screws are used to screw the drywall into the Resilient Channel. Screws should be the correct length in order to not pierce a stud, this will compromise the efficiency of the decoupled wall.[7]

Distance

The energy density of sound waves decreases as they become farther apart, so that increasing the distance between the receiver and source results in a progressively lesser intensity of sound at the receiver. In a normal three-dimensional setting, with a point source and point receptor, the intensity of sound waves will be attenuated according to the inverse square of the distance from the source.

Mass

Adding dense material to a treatment in order to stop sound waves from exiting a source wall, ceiling or floor. Use of Mass Loaded Vinyl, Drywall, Soundproof Sheetrock, Plywood, MDF, Concrete or Rubber. Different widths and densities in soundproofing material reduces sound within a variable frequency range. Use of multiple layers of material is essential to the success in any treatment.[8]

Reflection

When sound waves hit a medium, the reflection of that sound is dependent on dissimilarity of the surfaces it comes in contact with.[9] Sound hitting a concrete surface will result in a much different reflection than if the sound were to hit a softer medium such as fiberglass. In an outdoor environment such as highway engineering, embankments or paneling are often used to reflect sound upwards into the sky.

Diffusion

If a specular reflection from a hard flat surface is giving a problematic echo then an acoustic diffuser may be applied to the surface. It will scatter sound in all directions. This is effective to eliminate pockets of noise in a room.[10]

Noise cancellation

Noise cancellation generators for active noise control are a relatively modern innovation. A microphone is used to pick up the sound that is then analyzed by a computer; then, sound waves with opposite polarity (180° phase at all frequencies) are output through a speaker, causing destructive interference and canceling much of the noise.

Residential Soundproofing

Residential Sound Programs aims to decrease or eliminate the effects of exterior noise. The main focus of the residential sound program in existing structures is the windows and doors. Solid wood doors are a better sound barrier than hollow doors.[11] Curtains can be used to dampen sound, either through use of heavy materials or through the use of air chambers known as honeycombs. Single-, double- and triple-honeycomb designs achieve relatively greater degrees of sound damping. The primary soundproofing limit of curtains is the lack of a seal at the edge of the curtain, although this may be alleviated with the use of sealing features, such as hook and loop fastener, adhesive, magnets, or other materials. The thickness of glass will play a role when diagnosing sound leakage. Double-pane windows achieve somewhat greater sound damping than single-pane windows when well sealed into the opening of the window frame and wall.[12]

Significant noise reduction can also be achieved by installing a second interior window. In this case, the exterior window remains in place while a slider or hung window is installed within the same wall openings.[13]

In the USA the FAA offers sound-reducing for homes that fall within a noise contour where the average decibel level is 65 decibels. It is part of their Residential Sound Insulation Program. The program provides Solid-core wood entry doors plus windows and storm doors.[14]

Ceiling soundproofing

- Sealing gaps and cracks around electrical wiring, water pipes and ductwork using acoustical caulk or spray foam will significantly reduce unwanted noise as a preliminary step for ceiling soundproofing.

- Mineral wool insulation is most commonly used in soundproofing for its density and low cost in comparison to other soundproofing material. Spray foam insulation should only be used to fill gaps and cracks or as a 1-2 inch layer before installing mineral wool. Cured spray foam and other closed-cell foam can be a sound conductor. Spray foam is not porous enough to absorb sound, it's also not dense enough to stop sound.

- An effective method to reduce impact noise is the resilient isolation channel.[15] The channels decouple the drywall from the joists, reducing the transfer of vibration. Screws anchor the channels into the ceiling joist, staggering every other joist. The Channels rest 1/2" off the joist, using Resilient Isolation Clips or a rubber damping pad. After installation, impact vibration has minimal ways to transfer through the channels to the new drywall installation.

- When finishing the ceiling, acoustical caulk should be used along the perimeter of the wall and around all fixtures and duct registers to further seal the treatment. Avoid recessed lights or any fixtures requiring large holes in the ceiling. One small hole can compromise the efficiency of the entire treatment.[16]

Wall Soundproofing

- Outlets, light switches, and electrical boxes are weak points in any given soundproofing treatment. Electrical boxes should be wrapped in clay or putty and backed with MLV. After switch plates, outlet covers and lights are installed, acoustical caulking should be applied around the perimeter of the plates or fixtures.

- Mass is the only way to stop sound. Mass refers to drywall, plywood or concrete. MLV (Mass Loaded Vinyl) is used to damp or weaken sound waves between layers of mass. Use of a Viscoelastic Damping Compound[17] or MLV converts sound waves into heat, weakening the waves before reaching the next layer of mass.

- Walls are filled with Mineral Wool Insulation. Depending on the desired level of treatment, 2 layers of insulation may be required. Using Resilient Isolation Clips aids in the decoupling process for both wall and ceiling soundproofing treatments. After the clips are installed, the Resilient Isolation Channel easily clicks into the clips.

- Installing soundproof drywall is recommended for its higher STC value. Soundproof drywall in combination with a viscoelastic compound may achieve a noise reduction of STC 60+. It's important to use multiple layers of mass, in different widths and density, to optimize any given soundproofing treatment.[18]

Floor Soundproofing

Leaving a gap between the joist and subfloor plywood is the most efficient way to install soundproof flooring. Neoprene joist tape or u-shaped rubber spacers help decouple the subfloor from the joist. An additional layer of plywood can be installed with a viscoelastic compound. Mass Loaded Vinyl, in combination with open-cell rubber or a closed-cell foam floor underlayment, will further reduce sound transmission. After applying these techniques, hardwood flooring or carpeting can be installed. Additional area rugs and furniture will help reduce unwanted reflection within the room.

Room within a room

A room within a room (RWAR) is one method of isolating sound and preventing it from transmitting to the outside world where it may be undesirable.

Most vibration / sound transfer from a room to the outside occurs through mechanical means. The vibration passes directly through the brick, woodwork and other solid structural elements. When it meets with an element such as a wall, ceiling, floor or window, which acts as a sounding board, the vibration is amplified and heard in the second space. A mechanical transmission is much faster, more efficient and maybe more readily amplified than an airborne transmission of the same initial strength.

The use of acoustic foam and other absorbent means is less effective against this transmitted vibration. The user is advised to break the connection between the room that contains the noise source and the outside world. This is called acoustic decoupling. Ideal decoupling involves eliminating vibration transfer in both solid materials and in the air, so air-flow into the room is often controlled. This has safety implications: inside decoupled space, proper ventilation must be assured, and gas heaters cannot be used.

Commercial Soundproofing

Restaurants, schools, office businesses, and health care facilities use architectural acoustics to reduce noise for their customers. In the US, OSHA has requirements regulating the length of exposure of workers to certain levels of noise.[19]

Commercial businesses sometimes use soundproofing technology, especially when they are an open office design. There are many reasons why a business might implement soundproofing for their office. One of the biggest hindrances in worker productivity is the distracting noises that come from people talking such as on the phone, or with their co-workers and boss. Noise soundproofing is important in mitigating people from losing their concentration and focus from their work project. It is also important to keep confidential conversations secure to the intended listeners.

When trying to find places to install soundproofing, acoustic panels should be installed in office areas where many traffic corridors, circulation pathways, and open work areas are connected. Successful acoustic panel installations rely on three strategies and techniques to absorb sound, block sound transmission from one place to another, and cover and masking of the sound, positioned to avoid other services or block light.[20]

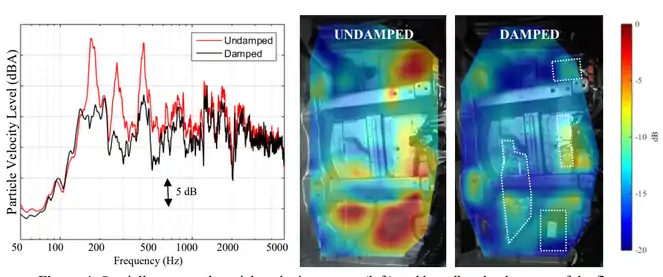

Automotive Soundproofing

Automotive soundproofing aims to decrease or eliminate the effects of exterior noise, primarily engine, exhaust and tire noise across a wide frequency range. When constructing a vehicle which includes soundproofing, a panel damping material is fitted which reduces the vibration of the vehicle's body panels when they are excited by one of the many high energy sound sources caused when the vehicle is in use.[21] There are many complex noises created within vehicles which change with the driving environment and speed at which the vehicle travels.[22] Significant noise reductions of up to 8 dB can be achieved by installing a combination of different types of materials.[23]

The automotive environment limits the thickness of materials that can be used, but combinations of dampers, barriers, and absorbers are common. Common materials include felt, foam, polyester, and Polypropylene blend materials. Waterproofing may be necessary based on materials used.[24] Acoustic foam can be applied in different areas of a vehicle during manufacture to reduce cabin noise. Foams also have cost and performance advantages in installation since foam material can expand and fill cavities after application and also prevent leaks and some gases from entering the vehicle. Vehicle soundproofing can reduce wind, engine, road, and tire noise. Vehicle soundproofing can reduce sound inside a vehicle from five to 20 decibels.[25]

Surface damping materials are very effective at reducing structure-borne noise. Passive damping materials have been used since the early 1960s in the aerospace industry. Over the years, advances in material manufacturing and the development of more efficient analytical and experimental tools to characterize complex dynamic behaviors enabled to expand the usage of these materials to the automotive industry. Nowadays, multiple viscoelastic damping pads are usually attached to the body in order to attenuate higher-order structural panel modes that significantly contribute to the overall noise level inside the cabin. Traditionally, experimental techniques are used to optimize the size and location of damping treatments. In particular, laser vibrometer type tests are often conducted on the body in white structures enabling the fast acquisition of a large number of measurement points with a good spatial resolution. However, testing a complete vehicle is mostly unfeasible, requiring to evaluate every subsystem individually, hence limiting the usability of this technology in a fast and efficient way. Alternatively, structural vibrations can also be acoustically measured using particle velocity sensors located near a vibrating structure. Several studies have revealed the potential of particle velocity sensors for characterizing structural vibrations, which remarkably accelerates the entire testing process when combined with scanning techniques.[26]

Noise barriers as exterior soundproofing

.jpg.webp)

Since the early 1970s, it has become common practice in the United States and other industrialized countries to engineer noise barriers along major highways to protect adjacent residents from intruding roadway noise. The Federal Highway Administration (FHWA) in conjunction with State Highway Administration (SHA) adopted Federal Regulation (23 CFR 772) requiring each state to adopt their own policy in regards to abatement of highway traffic noise.[27] Engineering techniques have been developed to predict an effective geometry for the noise barrier design in a particular real-world situation. Noise barriers may be constructed of wood, masonry, earth or a combination thereof. One of the earliest noise barrier designs was in Arlington, Virginia adjacent to Interstate 66, stemming from interests expressed by the Arlington Coalition on Transportation. Possibly the earliest scientifically designed and published noise barrier construction was in Los Altos, California in 1970.

See also

References

- Hawkins, Timothy Gerard (2014). Studies and research regarding sound reduction materials with the purpose of reducing sound (PDF) (PhD thesis). California Polytechnic State University. doi:10.15368/THESES.2014.121. S2CID 13922503 – via Semantic Scholar.

- "Acoustics of Buildings: including Acoustics of Auditoriums and Sound-proofing of Rooms". Nature. 114 (2855): 85. July 1924. doi:10.1038/114085b0. hdl:2027/mdp.39015031200952. ISSN 0028-0836. S2CID 46370464.

- Ghaffari Mosanenzadeh, Shahrzad (2014). Design, characterization and modeling of biobased acoustic foams (PhD thesis). University of Toronto. Bibcode:2014PhDT.......199G. hdl:1807/71305.

- Kulakov, Kirill; Romanovich, Marina (2019). "Technical comparison of soundproof wall panels" (PDF). E3S Web of Conferences. 91: 2, 4, 5. doi:10.1051/e3sconf/20199102027.

- Cox, Trevor J.; D'Antonio, Peter (2009). Acoustic Absorbers and Diffusers. ISBN 9780203893050.

- "Low frequency absorption". Studio tips.

- Bechis, Florin Mihai (2016-03-09). Rethink Home. Lulu Press, Inc. ISBN 978-1-329-93773-4.

- Shatzer, Ned. "Soundproofing-101". Hush Soundproofing. Retrieved 2020-02-12.

- "Reflection, Refraction, and Diffraction". www.physicsclassroom.com. Retrieved 2017-07-10.

- "Reduce Noise in your Home | Sound Control". soundcontroltech.com. Retrieved 2017-02-05.

- "How to sound-proof your noisy apartment". Stuff. Retrieved 2017-02-05.

- "Noise Control in Multi-Family Residential Buildings". Acoustical Surfaces. Retrieved 2017-07-10.

- Camtion, Eros. "What is more effective between active noise cancellation and soundproofing ?". berkeley.edu.

- Wisniewski, Mary. "City wants more Midway-area homeowners to sign up for soundproofing". chicagotribune.com. Retrieved 2017-02-05.

- Long, Marshall (2014-02-05). Architectural Acoustics. Academic Press. ISBN 978-0-12-398265-0.

- Shatzer, Ned (2020-02-12). "How to soundproof a room". Hush Soundproofing.

- Chakraborty, Bikash C.; Ratna, Debdatta (2020-01-31). Polymers for Vibration Damping Applications. Elsevier. ISBN 978-0-12-819253-5.

- "4. Physical Techniques to Reduce Noise Impacts - The Audible Landscape: A Manual for Highway Noise and Land Use - Federal Approach - Noise Compatible Planning - Noise - ENVIRonment - FHWA". www.fhwa.dot.gov. Retrieved 2020-02-13.

- "U.S. Standards on Workplace Noise Trail Those of Other Countries". New York Times.

- "Acoustic privacy considerations for open-plan offices". Atkar. Retrieved 24 June 2016.

- Neale, Paul. "How to reduce car noise". Car Insulation UK. CIUK. Retrieved 12 February 2015.

- Neale, Paul. "Mr". Car Insulation UK. CIUK.

- "Introduction to Car Audio: How to Tame That Road Noise". Secrets of Car Audio.

- UK Thinsulate literature.

- "DOW Automotive Systems: BETAFOAM™ acoustic foams" (PDF). dow.com. Retrieved 2017-05-26.

- Designing the damping treatment of a vehicle body (PDF).

- "Sound Barriers Guidelines - Highway Traffic Noise". roads.maryland.gov. Retrieved 2017-07-10.