Allotropes of iron

At atmospheric pressure, three allotropic forms of iron exist: alpha iron (α-Fe), gamma iron (γ-Fe), and delta iron (δ-Fe). At very high pressure, a fourth form exists, called epsilon iron (ε-Fe). Some controversial experimental evidence suggests the existence of a fifth high-pressure form that is stable at very high pressures and temperatures.[1]

.svg.png.webp)

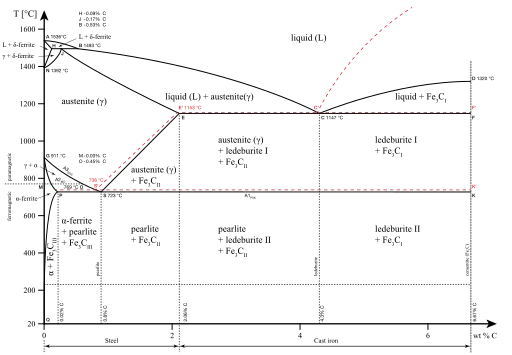

The phases of iron at atmospheric pressure are important because of the differences in solubility of carbon, forming different types of steel. The high-pressure phases of iron are important as models for the solid parts of planetary cores. The inner core of the Earth is generally assumed to consist essentially of a crystalline iron-nickel alloy with ε structure.[2][3][4] The outer core surrounding the solid inner core is believed to be composed of liquid iron mixed with nickel and trace amounts of lighter elements.

Standard pressure allotropes

Alpha iron (α-Fe)

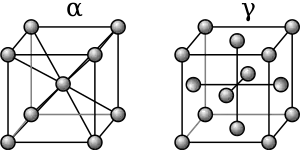

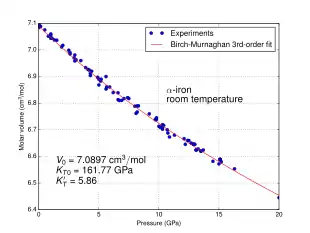

Below 912 °C (1,674 °F), iron has a body-centered cubic structure and is known as α-iron or ferrite. It is thermodynamically stable and fairly soft metal. α-Fe can be subjected to pressures up to ca. 15 GPa before transforming into a high-pressure form termed ε-iron, which crystallizes in a hexagonal close-packed (hcp) structure.

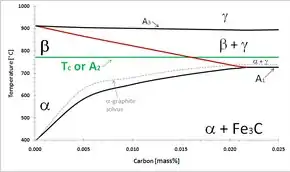

Magnetically, α-iron is paramagnetic at high temperatures. However, as it cools to 771 °C (1044K or 1420 °F),[5] the Curie temperature (TC or A2), it becomes ferromagnetic. The reverse also occurs: As α-iron is heated above the Curie temperature, the random thermal agitation of the atoms exceeds the oriented magnetic moment of the unpaired electron spins and it becomes paramagnetic.[6] In the past, the paramagnetic form of α-iron was known as Beta iron (β-Fe).[7][8] However, this terminology is obsolete and misleading, since as iron passes below the Curie temperature, the magnetic domains become aligned, but no structural change occurs. β-Fe is crystallographically identical to α-Fe, except for magnetic domains and the expanded body-centered cubic lattice parameter as a function of temperature, and is therefore of only minor importance in steel heat treating. For this reason, the beta "phase" is not usually considered a distinct phase but merely the high-temperature end of the alpha phase field. The A2 forms the boundary between the beta iron and alpha fields in the phase diagram in Figure 1.

Similarly, the A2 is of only minor importance compared to the A1 (eutectoid), A3 and Acm critical temperatures. The Acm, where austenite is in equilibrium with cementite + γ-Fe, is beyond the right edge in Fig. 1. The α + γ phase field is, technically, the β + γ field above the A2. The beta designation maintains continuity of the Greek-letter progression of phases in iron and steel: α-Fe, β-Fe, austenite (γ-Fe), high-temperature δ-Fe, and high-pressure hexaferrum (ε-Fe).

The primary phase of low-carbon or mild steel and most cast irons at room temperature is ferromagnetic α-Fe.[9][10] It has a hardness of approximately 80 Brinell.[11][12] The maximum solubility is about 0.02 wt% at 727 °C (1,341 °F) and 0.001% carbon at 0 °C (32 °F).[13] When it dissolves in iron, carbon atoms occupy interstitial "holes". Being about twice the diameter of the tetrahedral hole, the carbon introduces a strong local strain field.

Mild steel (carbon steel with up to about 0.2 wt% C) consist mostly of α-Fe and increasing amounts of cementite (Fe3C, an iron carbide). The mixture adopts a laminar structure called pearlite. Since bainite and pearlite each contain α-Fe as a component, any iron-carbon alloy will contain some amount of α-Fe if it is allowed to reach equilibrium at room temperature. The amount of α-Fe depends on the cooling process.

A2 critical temperature and induction heating

β-Fe and the A2 critical temperature are important in induction heating of steel, such as for surface-hardening heat treatments. Steel is typically austenitized at 900–1000 °C before it is quenched and tempered. The high-frequency alternating magnetic field of induction heating heats the steel by two mechanisms below the Curie temperature: resistance or Joule (I2R) heating and ferromagnetic hysteresis losses. Above the A2, the hysteresis mechanism disappears and the required amount of energy per degree of temperature increase is substantially larger than below A2. Load-matching circuits may be needed to vary the impedance in the induction power source to compensate for the change.[14]

Gamma iron (γ-Fe)

As the iron cools further to 1,394 °C (2,541 °F) its crystal structure changes to a face-centered cubic (FCC) crystalline structure. In this form it is called gamma iron (γ-Fe) or Austenite. γ-iron can dissolve considerably more carbon (as much as 2.04% by mass at 1,146 °C). This γ form of carbon saturation is exhibited in stainless steel.

Delta iron (δ-Fe)

As molten iron cools down, it solidifies at 1,538 °C (2,800 °F) into its δ allotrope, which has a body-centered cubic (BCC) crystal structure.[15] δ-iron can dissolve as much as 0.08% of carbon by mass at 1,475 °C.

High pressure allotropes

Epsilon iron / Hexaferrum (ε-Fe)

At pressures above approximately 10 GPa and temperatures of a few hundred kelvin or less, α-iron changes into a hexagonal close-packed (hcp) structure, which is also known as ε-iron or hexaferrum;[16] the higher-temperature γ-phase also changes into ε-iron, but does so at a higher pressure. Antiferromagnetism in alloys of epsilon-Fe with Mn, Os and Ru has been observed.[17]

Experimental high temperature and pressure

An alternate stable form, if it exists, may appear at pressures of at least 50 GPa and temperatures of at least 1,500 K; it has been thought to have an orthorhombic or a double hcp structure.[1] as of December 2011, recent and ongoing experiments are being conducted on high-pressure and Superdense carbon allotropes.

Phase transitions

Melting and boiling points

The melting point of iron is experimentally well defined for pressures less than 50 GPa.

For greater pressures, published data (as of 2007) put the γ-ε-liquid triple point at pressures that differ by tens of gigapascals and 1000 K in the melting point. Generally speaking, molecular dynamics computer simulations of iron melting and shock wave experiments suggest higher melting points and a much steeper slope of the melting curve than static experiments carried out in diamond anvil cells.[18]

The melting and boiling points of iron, along with its enthalpy of atomization, are lower than those of the earlier group 3d elements from scandium to chromium, showing the lessened contribution of the 3d electrons to metallic bonding as they are attracted more and more into the inert core by the nucleus;[19] however, they are higher than the values for the previous element manganese because that element has a half-filled 3d subshell and consequently its d-electrons are not easily delocalized. This same trend appears for ruthenium but not osmium.[20]

Structural phase transitions

The exact temperatures at which iron will transition from one crystal structure to another depends on how much and what type of other elements are dissolved in the iron. The phase boundary between the different solid phases is drawn on a binary phase diagram, usually plotted as temperature versus percent iron. Adding some elements, such as Chromium, narrows the temperature range for the gamma phase, while others increase the temperature range of the gamma phase. In elements that reduce the gamma phase range, the alpha-gamma phase boundary connects with the gamma-delta phase boundary, forming what is usually called the Gamma loop. Adding Gamma loop additives keeps the iron in a body-centered cubic structure and prevents the steel from suffering phase transition to other solid states.[21]

See also

References

- Boehler, Reinhard (2000). "High-pressure experiments and the phase diagram of lower mantle and core materials". Reviews of Geophysics. American Geophysical Union. 38 (2): 221–245. Bibcode:2000RvGeo..38..221B. doi:10.1029/1998RG000053. S2CID 33458168.

- Cohen, Ronald; Stixrude, Lars. "Crystal at the Center of the Earth". Archived from the original on 5 February 2007. Retrieved 2007-02-05.

- Stixrude, Lars; Cohen, R.E. (March 1995). "High-Pressure Elasticity of Iron and Anisotropy of Earth's Inner Core". Science. 267 (5206): 1972–5. Bibcode:1995Sci...267.1972S. doi:10.1126/science.267.5206.1972. PMID 17770110. S2CID 39711239.

- "What is at the centre of the Earth?". BBC News. 31 August 2011.

- Alloy Phase Diagrams. ASM Handbook. 3. ASM International. 1992. pp. 2.210, 4.9. ISBN 978-0-87170-381-1.

- Cullity, B.D.; Graham, C.D. (2009). Introduction to Magnetic Materials (2nd ed.). IEEE. p. 91. ISBN 978-0-471-47741-9.

- D. K. Bullens et al., Steel and Its Heat Treatment, Vol. I, Fourth Ed., J. Wiley & Sons Inc., 1938, p. 86.

- Avner, S.H. (1974). Introduction to physical metallurgy (2nd ed.). McGraw-Hill. p. 225. ISBN 978-0-07-002499-1.

- Maranian, Peter (2009), Reducing Brittle and Fatigue Failures in Steel Structures, New York: American Society of Civil Engineers, ISBN 978-0-7844-1067-7.

- Greenwood, Norman N.; Earnshaw, Alan (1997). Chemistry of the Elements (2nd ed.). Butterworth-Heinemann. ISBN 978-0-08-037941-8.

- Structure of plain steel, retrieved 2008-10-21.

- Alvarenga HD, Van de Putte T, Van Steenberge N, Sietsma J, Terryn H (January 2015). "Influence of Carbide Morphology and Microstructure on the Kinetics of Superficial Decarburization of C-Mn Steels". Metall Mater Trans A. 46 (1): 123–133. Bibcode:2015MMTA...46..123A. doi:10.1007/s11661-014-2600-y. S2CID 136871961.

- Smith & Hashemi 2006, p. 363.

- Semiatin, S.L.; Stutz, D.E. (1986). Induction Heat Treatment of Steel. ASM International. pp. 95–98. ISBN 978-0-87170-211-1.

- Lyman, Taylor, ed. (1973). Metallography, Structures and Phase Diagrams. Metals Handbook. 8 (8th ed.). Metals Park, Ohio: ASM International. OCLC 490375371.

- Mathon O; Baudelet F; Itié JP; Polian A; d'Astuto M; Chervin JC; Pascarelli S (14 December 2004). "Dynamics of the magnetic and structural alpha-epsilon phase transition in iron". Physical Review Letters. 93 (25): 255503. arXiv:cond-mat/0405439. Bibcode:2004PhRvL..93y5503M. doi:10.1103/PhysRevLett.93.255503. PMID 15697906. S2CID 19228886.

- G. C. Fletcher; R. P. Addis (November 1974). "The magnetic state of the phase of iron" (PDF). Journal of Physics F: Metal Physics. 4 (11). p. 1954. Bibcode:1974JPhF....4.1951F. doi:10.1088/0305-4608/4/11/020. Retrieved December 30, 2011.

- Boehler, Reinhard; Ross, M. (2007). "Properties of Rocks and Minerals_High-Pressure Melting". Mineral Physics. Treatise on Geophysics. 2. Elsevier. pp. 527–41. doi:10.1016/B978-044452748-6.00047-X. ISBN 9780444527486.

- Greenwood and Earnshaw, p. 1116

- Greenwood and Earnshaw, pp. 1074–75

- Myer Kurz, ed. (2002-07-22). Handbook of Materials Selection. p. 44. ISBN 9780471359241. Retrieved December 19, 2013.