Continental Aerospace Technologies

Continental Aerospace Technologies is an aircraft engine manufacturer located at the Brookley Aeroplex in Mobile, Alabama, United States. It was originally spun off from automobile engine manufacturer Continental Motors Company in 1929 and owned by Teledyne Technologies from 1969 until December 2010. The company is now part of Aviation Industry Corporation of China (AVIC), which is a Government of the People's Republic of China state-owned aerospace company headquartered in Beijing.[1][2]

| |

| Type | Division |

|---|---|

| Industry | Aircraft engines |

| Predecessor | Continental Motors Corporation |

| Founded | 1929 |

| Headquarters | , |

Key people | Robert Stoppek, CEO |

| Owner | Aviation Industry Corporation of China |

| Parent |

|

| Website | http://continental.aero |

Although Continental is most well known for its engines for light aircraft, it was also contracted to produce the air-cooled V-12 AV-1790-5B gasoline engine for the U.S. Army's M47 Patton tank and the diesel AVDS-1790-2A and its derivatives for the M48, M60 Patton, and Merkava main battle tanks. The company also produced engines for various independent manufacturers of automobiles, tractors, and stationary equipment (pumps, generators, and machinery drives) from the 1920s to the 1960s.

History

In 1929, the company introduced its first aircraft engine,[3] a seven-cylinder radial designated as the A-70, with a displacement of 543.91 cu in (8.91L) that produced 170 hp (127 kW). In August 1929, the Continental Motors Company formed the Continental Aircraft Engine Company as a subsidiary to develop and produce its aircraft engines.[4]

As the Great Depression unwound, 1930 saw the company introduce the 37 hp (28 kW) A-40 four-cylinder engine. A follow-on design, the 50 hp (37 kW) A-50 was introduced in 1938 and was used to power the Taylor Cub and derivative Piper Cub. As the Second World War started in 1939 Continental commenced building aircraft engines for use in British and American tanks.[5][6] Continental formed Continental Aviation and Engineering (CAE) in 1940 to develop and produce aircraft engines of over 500 hp (373 kW)[4] Continental ranked 38th among United States corporations in the value of wartime production contracts.[7]

During the late 1930s, early 1940s the Gray Marine Motor Company adapted Continental engines for maritime use. On 14 June 1944 the company was purchased by Continental for US$2.6 million. John W. Mulford, the son of one of Gray's founders was appointed general manager of Gray by Continental. Gray's continued to make marine engines in the post-war period until its closure by Continental in about 1967.[8][9]

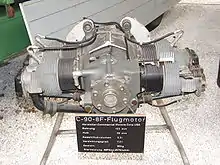

During the 1950s, the A-65 was developed into the more powerful 90 hp (67 kW) C-90 and eventually into the 100 hp (75 kW) O-200. The O-200 powered a very important airplane design milestone: the Cessna 150. By the 1960s turbocharging and fuel injection arrived in general aviation and the company's IO-520 series came to dominate the market.

In 1965, Ryan Aeronautical acquired a 50% stake in Continental Motors.[10]

In 1969, Teledyne Incorporated acquired Continental Motors, which became Teledyne Continental Motors (TCM).[11] That same year, the Continental Tiara series of high output engines were introduced, although they were dropped from the line after 1978. The company brought the TSIO-520-BE for the Piper PA-46 to market in 1984 and it set new efficiency standards for light aircraft piston engines. Powered by a liquid-cooled version of the IO-240, the Rutan Voyager was the first piston-powered aircraft to circumnavigate the world without refueling in 1986.

NASA selected Continental to develop and produce GAP in 1997, a new 200 hp (150 kW) piston engine to operate on Jet-A fuel. This was in response to 100-octane aviation gasoline becoming less available as a result of decreased demand, due to smaller turboprop engines becoming more prevalent.

In 2008, Teledyne Continental's new president, Rhett Ross announced that the company was very concerned about future availability of 100LL avgas and as a result would develop a diesel engine in the 300 hp (220 kW) range for certification in 2009 or 2010.[12] By the fall of 2009 the company was feeling the effects of the economic situation and the resulting reduced demand for aircraft engines. The company announced that it would close its plant for two one-week periods in October 2009 and January 2010. Salaried employees would move to a four-day work week with one week vacations for Thanksgiving and Christmas, with the aim "to protect as much of our valuable employee base as possible".[13]

On December 14, 2010, Continental's parent Teledyne announced that Teledyne Continental Motors, Teledyne Mattituck Services, and its general aviation piston engine business would be sold to Technify Motor (USA) Ltd, a subsidiary of AVIC International, for US$186 million in cash. AVIC is a Chinese state-owned aerospace company. In May 2011, the transaction was reported as complete and the company renamed Continental Motors, Inc.[1][2][14]

On 23 July 2013 the company bought diesel aircraft engine manufacturer Thielert from bankruptcy for an undisclosed sum. Thielert will become an operating division of Continental and will be renamed Technify Motors GmbH.[15]

In March 2019 the company name was changed from Continental Motors, Inc. to Continental Aerospace Technologies.[16]

Continental aircraft engines

Opposed piston engines

- A-40 – four-cylinder, 40-horsepower[17]

- A-50 – four-cylinder, 50-horsepower[17]

- A-65 – four-cylinder, 65-horsepower, 80-octane, 1800-hour design time between overhauls[18]

- A-75 – four-cylinder, 75-horsepower[17]

- C-75 – four-cylinder, 75-horsepower[17]

- A-80 – four-cylinder, 80-horsepower[17]

- C-85 – four-cylinder, 85-horsepower, 80-octane, 1800-hour design time between overhauls[18]

- C-90 – four-cylinder, 90-horsepower, 80-octane, 1800-hour design time between overhauls[18]

- Continental Tiara 4-180 – O-270, four-cylinder, 180-horsepower, 1970

- C-115 – six-cylinder, 115 horsepower (86 kW) based on the same cylinders as the C-75.

- C-125 – six-cylinder, 125-horsepower, 80-octane, 1800-hour design time between overhauls[18]

- C-140 – six-cylinder, a higher rpm version of the C-125.

- C-145 – six-cylinder, 145-horsepower, 80-octane, 1800-hour design time between overhauls[18]

- C-175 – geared version of the C-145, a six-cylinder, 175-horsepower at 3200 RPM, 80-octane, 1500-hour design time between overhauls, also designated as the GO-300[18]

- E165 – six-cylinder, 165-horsepower, 80-octane, 1500-hour design time between overhauls[18]

- E185 – six-cylinder, 185-horsepower, 80-octane, 1500-hour design time between overhauls[18]

- O-200 – four-cylinder, 100-horsepower, 80-octane, 1800-hour design time between overhauls[18]

- E225 – six-cylinder, 225-horsepower, 80-octane, 1500-hour design time between overhauls[18]

- O-240 – four-cylinder, 125-horsepower, 1971

- Continental O-300 – six-cylinder, 145-horsepower, 80-octane, 1800-hour design time between overhauls. Family includes the GO-300. The O-300 is a modernized version of the C-145[18]

- Continental IO-346 – four-cylinder, 165-horsepower, 91-octane[17]

- Continental IO-360 – six-cylinder, 210-horsepower, 100-octane, 1500-hour design time between overhauls. Family includes the TSIO-360[18]

- Continental IO-370 - four-cylinder, 180-hoursepower, 2200-hour design time between overhauls,

- Continental Tiara, O-405, six-cylinder, '6-285' '6-320', 285-320-horsepower, 1969–1975,

- Continental O-470 – six-cylinder, 230-horsepower, 80-octane, design time between overhauls 1500-hour or every 12 years. Family includes the IO-470 and the TSIO-470[18]

- Continental O-520 – six-cylinder, 320-horsepower, 100-octane, 1500-hour design time between overhauls. Family includes the TSIO-520 and the GTSIO-520[18]

- Continental O-526 – six-cylinder, 270–300–310-horsepower, 1957, FSO- GSO- GO-

- Continental Tiara, O-540, eight-cylinder, '8-380' 'T8-450', 380–450-horsepower, 1970

- Continental IO-550 – six-cylinder 280 hp (209 kW) to 360 hp (268 kW) 100-octane, engine, Family includes IOF-550 and TSIO-550.[19][20]

- Continental TD-300 – four-cylinder, 230–250 hp Diesel and Jet A–fueled prototype engine, 2010.

Radial and Inverted-V engines

- R-545 A-70

- I-1430

- R-670 light tank M3 Stuart engine

- R-975 tank destroyer M18 Hellcat engine

Turboprop/turboshafts

- Continental T51

- Continental T65

- Continental T67

- Continental T69

- Continental T72

- Continental TP-500[21]

Jet engines

- Teledyne CAE J69

- Continental RJ35 Ramjet[22][23]

- Continental RJ45 Ramjet

- Continental RJ49 Ramjet

See also

References

- AvWeb Staff (December 2010). "Teledyne-Continental Bought by Chinese Interests". AvWeb. Retrieved 14 December 2010.

- Teledyne Technologies Incorporated (December 2010). "Teledyne Technologies Agrees to Sell Teledyne Continental Motors to AVIC International". Business Wire. Retrieved 14 December 2010.

- Strohl, Daniel in Hemmings Classic Car, December, 2008, "Powerful As The Nation", pg 43: "...by the end of 1905. According to Continental's own history, the company also began aircraft engine development at about the same time, rolling out the 45hp Model O four-cylinder L-head engine about 1906 or 1907.",.

- Leyes, p. 87.

- Borth, Christy. Masters of Mass Production, pp. 63-5, Bobbs-Merrill Company, Indianapolis, IN, 1945.

- Herman, Arthur. Freedom's Forge: How American Business Produced Victory in World War II, pp. 96-100, 126, 200, Random House, New York, New York, 2012. ISBN 978-1-4000-6964-4.

- Peck, Merton J. & Scherer, Frederic M. The Weapons Acquisition Process: An Economic Analysis (1962) Harvard Business School p.619

- A Brief History of the Gray Marine Motor Company, Gas Engine Magazine

- Grayson, Stan. Engines Afloat, Vol. II (Marblehead, MA: Devereaux Books, 1999), p.116.

- Leyes, Richard A., and William A. Fleming, The History of North American Small Gas Turbine Aircraft Engines, Smithsonian Institution, Washington, DC, 1999: p.143 ISBN 1-56347-332-1

- Gunston, p. 225.

- AvWeb Staff (February 2008). "Teledyne Continental Plans Certified Diesel Within Two Years". Retrieved 2008-02-18.

- Pew, Glenn (October 2009). "TCM Announces Temporary Plant Closures, More". Retrieved 2009-10-05.

- Niles, Russ (May 2011). "China Lays Out Its GA Plan". AvWeb. Retrieved 5 May 2011.

- Bertorelli, Paul (23 July 2013). "Continental Buys Thielert Aircraft Engines". AVweb. Retrieved 14 July 2013.

- Bertorelli, Paul (29 March 2019). "Continental Motors Gets a New Name". AVweb. Retrieved 15 March 2019.

- Christy, Joe: Engines for Homebuilt Aircraft & Ultralights, p. 142. Tab Books Inc, 1983. ISBN 0-8306-2347-7.

- Foster, Timothy R.V.: The Aviator's Catalog, p. 142. Van Nostrand Reinhold, 1981. ISBN 0-442-21201-1.

- Federal Aviation Administration (6 April 2020). "Type Certificate Data Sheet No. E3SO Revision 12". Retrieved 27 July 2020.

- Federal Aviation Administration (31 March 2020). "Type Certificate Data Sheet No. E5SO Revision 3". Retrieved 27 July 2020.

- Leyes, p. 121.

- FM 30- 30 Aircraft Recognition Manual Supplement No. 6. United States Department of the Army. December 1956. p. 20. ISBN 9780359123834. Retrieved 2020-03-29.

- Navy Training Course: Aviation Machinist's Mate 3. Bureau of Naval Personnel. United States Navy. 1957. p. 133. Retrieved 2020-03-29.

- Foss, Christopher F. (1974). Jane's Pocket Book of Modern Tanks and Armored Fighting Vehicles. Collier Books. pp. 45–49. 73-15286.

- Gunston, Bill (2006). World Encyclopedia of Aero Engines, 5th Edition. Phoenix Mill, Gloucestershire, England, UK: Sutton Publishing Limited. ISBN 0-7509-4479-X.

- Leyes II, Richard A.; William A. Fleming (1999). The History of North American Small Gas Turbine Aircraft Engines. Washington, DC: Smithsonian Institution. ISBN 1-56347-332-1.

External links

| Wikimedia Commons has media related to Continental aircraft engines. |