Electrocatalyst

An electrocatalyst is a catalyst that participates in electrochemical reactions. Catalyst materials modify and increase the rate of chemical reactions without being consumed in the process. Electrocatalysts are a specific form of catalysts that function at electrode surfaces or may be the electrode surface itself. An electrocatalyst can be heterogeneous such as a platinum surface or nanoparticles,[1][2] or homogeneous like a coordination complex or enzyme. The electrocatalyst assists in transferring electrons between the electrode and reactants, and/or facilitates an intermediate chemical transformation described by an overall half-reaction.

Context

There are multiple ways for many transformations to occur. For example, hydrogen and oxygen can be combined to form water through a free-radical mechanism commonly referred to as combustion. Useful energy can be obtained from the thermal heat of this reaction through an internal combustion engine with an upper efficiency of 60% (for compression ratio of 10 and specific heat ratio of 1.4) based on the Otto thermodynamic cycle. It is also possible to combine the hydrogen and oxygen through redox mechanism as in the case of a fuel cell. In this process, the reaction is broken into two half-reactions which occur at separate electrodes. In this situation the reactant's energy is directly converted to electricity.[3][4]

| Half-reaction | E° (V) |

|---|---|

| H2(g) 2H+ + 2e− | ≡ 0 |

| O2(g) + 4 H+ + 4 e− 2 H2O | +1.23 |

This process is not governed by the same thermodynamic cycles as combustion engines, it is governed by the total energy available to do work as described by the Gibbs free energy. In the case of this reaction, that limit is 83% efficient at 298K.[5] This half-reaction pair and many others don't achieve their theoretical limit in practical application due to lack of an effective electrocatalyst.

One of the greatest drawbacks to galvanic cells, like fuel cells and various forms of electrolytic cells, is that they can suffer from high activation barriers. The energy diverted to overcome these activation barriers is transformed into heat. In most exothermic combustion reactions this heat would simply propagate the reaction catalytically. In a redox reaction, this heat is a useless byproduct lost to the system. The extra energy required to overcome kinetic barriers is usually described in terms of low faradaic efficiency and high overpotentials. In the example above, each of the two electrodes and its associated half-cell would require its own specialized electrocatalyst.

Half-reactions involving multiple steps, multiple electron transfers, and the evolution or consumption of gases in their overall chemical transformations, will often have considerable kinetic barriers. Furthermore, there is often more than one possible reaction at the surface of an electrode. For example, during the electrolysis of water, the anode can oxidize water through a two electron process to hydrogen peroxide or a four electron process to oxygen. The presence of an electrocatalyst could facilitate either of the reaction pathways.[6]

Like other catalysts, an electrocatalyst lowers the activation energy for a reaction without altering the reaction equilibrium. Electrocatalysts go a step further than other catalysts by lowering the excess energy consumed by a redox reaction's activation barriers.

Heterogeneous electrocatalysis

Since electrochemical reactions need an electron transfer between the solid catalyst (typically a metal) and the electrolyte, which can be a liquid solution but also a polymer or a ceramic capable of ionic conduction, the reaction kinetics depend on both the catalyst and the electrolyte as well as on the interface between them. The nature of the electrocatalyst surface determines some properties of the reaction such as its rate and products selectivity.

The activity of an electrocatalyst can be tuned with a chemical modification, commonly obtained by alloying two or more metals. This is due to a change in the electronic structure, especially in the d band which is considered to be responsible for the catalytic properties of noble metals.[7]

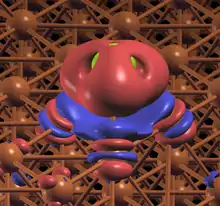

Also, higher reaction rates can be achieved by precisely controlling the arrangement of surface atoms: indeed, in nanometric systems the number of available reaction sites is a better parameter than the exposed surface area in order to estimate electrocatalytic activity. Sites are the positions where the reaction could take place; the likelihood of a reaction to occur in a certain site depends on the electronic structure of the catalyst, which determines the adsorption energy of the reactants together with many other variables not yet fully clarified.

According to the TSK model, the catalyst surface atoms can be classified as terrace, step or kink atoms according to their position, each characterized by a different coordination number. In principle, atoms with lower coordination number (kinks and defects) tend to be more reactive and therefore adsorb the reactants more easily: this may promote kinetics but could also depress it if the adsorbing species isn't the reactant, thus inactivating the catalyst.

Advances in nanotechnology make it possible to surface engineer the catalyst so that just some desired crystal planes are exposed to reactants, maximizing the number of effective reaction sites for the desired reaction.

To date, a generalized surface dependence mechanism cannot be formulated since every surface effect is strongly reaction-specific. A few classifications of reactions based on their surface dependence have been proposed[8] but there are still too many exceptions that do not fall into them.

Particle size effect

The interest in reducing as much as possible the costs of the catalyst for electrochemical processes led to the use of fine catalyst powders since the specific surface area increases as the average particle size decreases. For instance, most common PEM fuel cells and electrolyzers design is based on a polymeric membrane charged in platinum nanoparticles as an electrocatalyst (the so-called platinum black).[9]

Although the surface area to volume ratio is commonly considered to be the main parameter relating electrocatalyst size with its activity, to understand the particle-size effect several more phenomena need to be taken into account:[8]

- Equilibrium shape: for any given size of a nanoparticle there is an equilibrium shape which exactly determines its crystal planes

- Reaction sites relative number: a given size for a nanoparticle corresponds to a certain number of surface atoms and only some of them host a reaction site

- Electronic structure: below a certain size, the work function of a nanoparticle changes and its band structure fades away

- Defects: the crystal lattice of a small nanoparticle is perfect; thus, reactions enhanced by defects as reaction sites get slowed down as the particle size decreases

- Stability: small nanoparticles have the tendency to lose mass due to the diffusion of their atoms towards bigger particles, according to the Ostwald ripening phenomenon

- Capping agents: in order to stabilize nanoparticles it is necessary a capping layer, therefore part of their surface is unavailable for reactants

- Support: nanoparticles are often fixed onto a support in order to stay in place, therefore part of their surface is unavailable for reactants

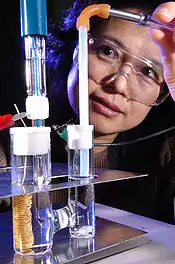

Ethanol-powered fuel cells

An electrocatalyst of platinum and rhodium on carbon backed tin-dioxide nanoparticles can break carbon bonds at room temperature with only carbon dioxide as a by-product, so that ethanol can be oxidized into the necessary hydrogen ions and electrons required to create electricity.[10]

References

- Valenti, G.; Boni, A.; Melchionna, M.; Cargnello, M.; Nasi, L.; Bertoli, G.; Gorte, R. J.; Marcaccio, M.; Rapino, S.; Bonchio, M.; Fornasiero, P.; Prato, M.; Paolucci, F. (2016). "Co-axial heterostructures integrating palladium/titanium dioxide with carbon nanotubes for efficient electrocatalytic hydrogen evolution". Nature Communications. 7: 13549. Bibcode:2016NatCo...713549V. doi:10.1038/ncomms13549. PMC 5159813. PMID 27941752.

- Wang, Xin (19 January 2008). "CNTs tuned to provide electrocatalyst support". Nanotechweb.org. Archived from the original on 22 January 2009. Retrieved 27 February 2009.

- Kunze, Julia; Ulrich Stimming (2009). "Electrochemical Versus Heat-Engine Energy Technology: A Tribute to Wilhelm Ostwald's Visionary Statements". Angewandte Chemie International Edition. 48 (49): 9230–9237. doi:10.1002/anie.200903603. PMID 19894237.

- Haverkamp, Richard (3 June 2008). "What is an electrocatalyst?" (QuickTime video and transcript). Science learning New Zealand. Retrieved 27 February 2009.

- Fuel Cell efficiency Archived 2014-02-09 at the Wayback Machine

- Bard, Allen J.; Faulkner, Larry R. (January 2001). Electrochemical methods: fundamentals and applications. New York: Wiley. ISBN 978-0-471-04372-0. Retrieved 27 February 2009.

- Mistry, H.; Varela, A.S.; Strasser, P.; Cuenya, B.R. (2016). "Nanostructured electrocatalysts with tunable activity and selectivity". Nature Reviews Materials. 1 (4): 1–14. Bibcode:2016NatRM...116009M. doi:10.1038/natrevmats.2016.9.

- Koper, M.T.M. (2011). "Structure sensitivity and nanoscale effects in electrocatalysis". Nanoscale. The Royal Society of Chemistry. 3 (5): 2054–2073. Bibcode:2011Nanos...3.2054K. doi:10.1039/c0nr00857e. PMID 21399781.

- Carmo, M.; Fritz, D.L.; Mergel, J.; Stolten, D. (2013). "A comprehensive review on PEM water electrolysis". International Journal of Hydrogen Energy. 38 (12): 4901–4934. doi:10.1016/j.ijhydene.2013.01.151.

- Harris, Mark (26 January 2009). "Booze-powered cars coming soon". techradar.com. Archived from the original on 2 March 2009. Retrieved 27 February 2009.