Lead frame

Lead frames are the metal structures inside a chip package that carry signals from the die to the outside.

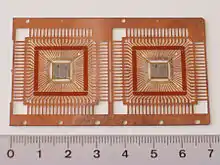

Classically the leadframe consists of different parts; The central die pad part, where the die is to be placed, usually multiple bond pads, where the bond wires are placed to connect the chip to the outer part, and the leads, which are metal structures connecting the inside of the semiconductor package with the outside. Additionally there are mechanical connections to fix all these parts inside a frame structure, which makes the whole leadframe easy to handle automatically.

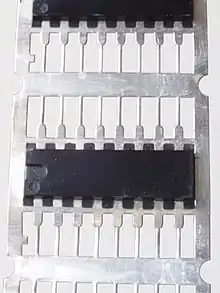

The die inside the package is typically glued or soldered to the die pad inside the lead frame, and then bond wires connect the die to the leads via the bond pads. In the last stage of the manufacturing process, the lead frame is moulded in a plastic case, and is cut-off outside of the mold body, separating all leads by removing the holding structures at least enough to achieve an electrical insulation. A bending of the external leads can form the usual shapes.

Manufacturing

Lead frames are manufactured by removing material from a flat plate of copper or copper-alloy. Two processes used for this are etching (suitable for high density of leads), or stamping (suitable for low density of leads). Mechanical bending process can be applied after both techniques.[1]

Uses

Amongst others, leadframes are used to manufacture a quad flat no-leads package (QFN), a quad flat package (QFP), or a dual in-line package (DIP).

See also

- Chip carrier – Chip packaging and package types list