Piezoelectric motor

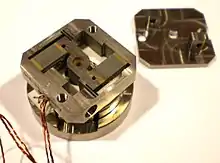

A piezoelectric motor or piezo motor is a type of electric motor based on the change in shape of a piezoelectric material when an electric field is applied. Piezoelectric motors use the converse piezoelectric effect of piezoelectric sensors, in which deformation or vibration of the piezoelectric material produces an electric charge. An electrical circuit makes acoustic or ultrasonic vibrations in the piezoelectric material, which produce linear or rotary motion. In one mechanism, the elongation in a single plane makes a series of stretches and position holds, analogous to the way a caterpillar moves.[2]

Current designs

One drive technique uses piezoelectric ceramics to push a stator. These piezoelectric motors use three groups of crystals—two locking, and one motive that permanently connects to either the motor's casing or stator (not both). The motive group, sandwiched between the other two, provides the motion. These piezoelectric motors are fundamentally stepping motors, with each step comprising either two or three actions, based on the locking type. These motors are also known as inchworm motors. Another mechanism uses surface acoustic waves (SAW) to generate linear or rotational motion.

A second drive type, the squiggle motor, uses piezoelectric elements bonded orthogonally to a nut. Their ultrasonic vibrations rotate a central lead screw. This is a direct drive mechanism.

Locking mechanisms

The non-powered behaviour of the first type of piezoelectric motor is one of two options: normally locked or normally free. When no power is applied to a normally locked motor, the spindle or carriage (for rotary or linear types, respectively) does not move under external force. A normally free motor's spindle or carriage does move freely under external force. However, if both locking groups are powered at rest, a normally free motor resists external force without providing any motive force.

A combination of mechanical latches and crystals can do the same thing, but would restrict the maximum stepping rate of the motor. The non-power behaviour of the second type of motor is locked, as the drive screw is locked by the threads on the nut. Thus it holds its position with the power off.

Stepping actions

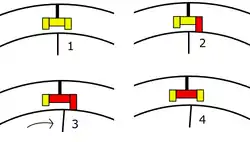

Regardless of locking type, stepping type piezoelectric motors—linear and rotary—use the same mechanism to create movement:

- First, one group of locking crystals is activated to lock one side and unlock other side of the 'sandwich' of piezo crystals.

- Next, the motive crystal group is triggered and held. The expansion of this group moves the unlocked locking group along the motor path. This is the only stage where the motor moves.

- Then the locking group triggered in stage one releases (in normally locking motors, in the other it triggers).

- Then the motive group releases, retracting the 'trailing' locking group.

- Finally, both locking groups return to their default states.

Direct drive actions

The direct drive piezoelectric motor creates movement through continuous ultrasonic vibration. Its control circuit applies a two-channel sinusoidal or square wave to the piezoelectric elements that matches the bending resonant frequency of the threaded tube—typically an ultrasonic frequency of 40 kHz to 200 kHz. This creates orbital motion that drives the screw.

Speed and precision

The growth and forming of piezoelectric crystals is a well-developed industry, yielding very uniform and consistent distortion for a given applied potential difference. This, combined with the minute scale of the distortions, gives the piezoelectric motor the ability to make very fine steps. Manufacturers claim precision to the nanometer scale. High response rate and fast distortion of the crystals also let the steps happen at very high frequencies—upwards of 5 MHz. This provides a maximum linear speed of approximately 800 mm per second, or nearly 2.9 km/h.

A unique capability of piezoelectric motors is their ability to operate in strong magnetic fields. This extends their usefulness to applications that cannot use traditional electromagnetic motors—such as inside nuclear magnetic resonance antennas. The maximum operating temperature is limited by the Curie temperature of the used piezoelectric ceramic and can exceed +250C.

Other designs

Single action

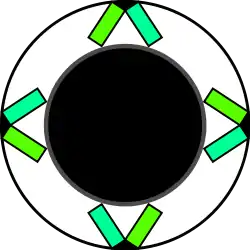

Very simple single-action stepping motors can be made with piezoelectric crystals. For example, with a hard and rigid rotor-spindle coated with a thin layer of a softer material (like a polyurethane rubber), a series of angled piezoelectric transducers can be arranged. (see Fig. 2). When the control circuit triggers one group of transducers, they push the rotor one step. This design cannot make steps as small or precise as more complex designs, but can reach higher speeds and is cheaper to manufacture.

Patents

The first U.S. patent to disclose a vibrationally-driven motor may be "Method and Apparatus for Delivering Vibratory Energy" (U.S. Pat. No. 3,184,842, Maropis, 1965). The Maropis patent describes a "vibratory apparatus wherein longitudinal vibrations in a resonant coupling element are converted to torsional vibrations in a toroid type resonant terminal element." The first practical piezomotors were designed and produced by V. Lavrinenko in Piezoelectronic Laboratory, starting 1964, Kiev Polytechnic Institute, USSR. Other important patents in the early development of this technology include:

- "Electrical motor", V. Lavrinenko, M. Nekrasov, Patent USSR # 217509, priority May 10, 1965.

- "Piezoelectric motor structures" (U.S. Pat. No. 4,019,073, Vishnevsky, et al., 1977)

- "Piezoelectrically driven torsional vibration motor" (U.S. Pat. No. 4,210,837, Vasiliev, et al., 1980)

See also

References

- attocube rotator ANR101

- attocube. "Working principle of attocube's positioners".