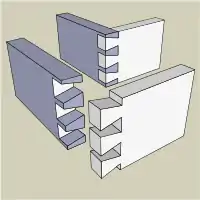

Dovetail joint

A dovetail joint or simply dovetail is a joinery technique most commonly used in woodworking joinery (carpentry), including furniture, cabinets,[1] log buildings, and traditional timber framing. Noted for its resistance to being pulled apart (tensile strength), the dovetail joint is commonly used to join the sides of a drawer to the front. A series of 'pins' cut to extend from the end of one board interlock with a series of 'tails' cut into the end of another board. The pins and tails have a trapezoidal shape. Once glued, a wooden dovetail joint requires no mechanical fasteners.

History

The dovetail joint technique probably pre-dates written history. Some of the earliest known examples of the dovetail joint are in ancient Egyptian furniture entombed with mummies dating from First Dynasty, the tombs of Chinese emperors, and a stone pillar at the Vazhappally Maha Siva Temple in India. The dovetail design is an important method of distinguishing various periods of furniture.

In Europe, the dovetail joint is sometimes called a swallowtail joint, a culvertail joint (culver also means 'dove'), or a fantail joint.[2]

Methods

The dovetail joint is very strong because of the way the 'tails' and 'pins' are shaped. This makes it difficult to pull the joint apart and virtually impossible when glue is added. This type of joint is used in box constructions such as drawers, jewellery boxes, cabinets and other pieces of furniture where strength is required. It is a difficult joint to make manually, requiring skilled workmanship. There are different types of dovetail joints.

The angle of slope varies according to the wood used, purpose of joint and type of work. Typically the slope is 1:6 for softwoods, and a shallower 1:8 slope for hardwoods. Often a slope of 1:7 is used as a compromise. However, a different slope does not affect the strength of the joint in different types of wood.[3]

Types of dovetails

Through dovetail

The image at the top of this page shows a 'through dovetail' (also known as 'plain dovetail') joint, where the end grain of both boards is visible when the joint is assembled.[4] Through dovetails are common in carcass and box construction. Traditionally, the dovetails would have often been covered by a veneer. However, dovetails have become a signature of craftsmanship and are generally considered a feature, so they are rarely concealed in contemporary work. When used in drawer construction, a through (or blind, mitred, or lapped) dovetail joint is sometimes referred to as an "English dovetail."[5]

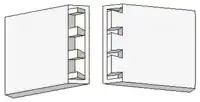

Half-blind dovetail

Craftsmen use a 'half-blind dovetail' when they do not want the end grain visible from the front of the joint. The tails fit into mortises in the ends of the board that is the front of the item, hiding their ends.

Half-blind dovetails are commonly used to fasten drawer fronts to drawer sides. This is an alternative to the practice of attaching false fronts to drawers constructed using through dovetails.

Secret mitred dovetail

The 'secret mitred dovetail' joint (also called a 'mitred blind dovetail', 'full-blind dovetail', or 'full-blind mitred dovetail') is used in the highest class of cabinet and box work. It offers the strength found in the dovetail joint but is totally hidden from both outside faces by forming the outer edge to meet at a 45-degree angle while hiding the dovetails internally within the joint.

The mitred corner dovetail joint is very similar in design, but it has just a single dovetail and is used for picture frames and other similar joins.[6]

Secret double-lapped dovetail

The secret double-lapped dovetail is similar to the secret mitred dovetail, but presents a very thin section of end grain on one edge of the joint. Used for carcass and box construction to hide the dovetails completely from view.

Sliding dovetail

The sliding dovetail is a method of joining two boards at right angles, where the intersection occurs within the field of one of the boards, that is not at the end. This joint provides the interlocking strength of a dovetail. Sliding dovetails are assembled by sliding the tail into the socket. It is common to slightly taper the socket, making it slightly tighter towards the rear of the joint, so that the two components can be slid together easily but the joint becomes tighter as the finished position is reached. Another method to implement a tapered sliding dovetail is to taper the tail instead of the socket. When used in drawer construction, a "stopped sliding dovetail" that does not extend across the full width of the board is sometimes referred to as a "French dovetail".[5]

Used for:

- Joining shelves to cabinet sides

- Joining cabinet bottoms to sides

- Joining horizontal partitions to shelves

- Joining adjacent sections of expandable table frames

- Joining drawer fronts to sides

- Joining front rails of web frames to cabinet sides

- Joining neck and body in violins and some guitars.

Non-woodworking dovetails

Dovetails are most commonly, but not exclusively, used in woodworking. Other areas of use are:

- Dovetail slides, for example on a lathe.[7]

- Attaching turbine blades to the shaft in jet engines and other applications.[8]

- Clockmaking: dovetailing a new tooth, when replacing broken teeth in clock gears.

- Masonry: dovetail construction is regarded a major step forward in the design of lighthouses meant for particularly dangerous areas; the Eddystone Lighthouse and Fastnet Lighthouse are examples of the durable quality of dovetail masonry.

- 3D printing: dovetail is commonly used to overcome physical object print size limitation of a 3D printer.[9]

- Iron sights on firearms may be affixed via a dovetail rail to the receiver or slide.

References

- carcase construction

- Routledge French technical dictionary. 1. London: Routledge. 1994. ISBN 9780415112253.

- The relationship between dovetail angle and joint strength (PDF). 1958.

- "Dovetail Case Joints". Woodwork Details. Retrieved February 6, 2015.

- "What's in Your Drawers". Furniche. Retrieved 9 November 2015.

- "Dovetail Joints: Different Types and Their Uses". ToolsToday. Retrieved February 6, 2015.

- "How to get the most out of your lathes". Popular Science. 142 (2): 244. February 1943. Retrieved February 6, 2015.

- Hahn, Youngwon; Cofer, John I. (May 1, 2013). "Optimization of Turbine Blade Dovetail Geometry". NASA Tech Briefs. Retrieved February 6, 2015.

- Martinson, Eiki. "Mechanical Design for 3D Printing - Dovetail Joints". The Adventures of Eiki Martinson. Retrieved February 6, 2015.

Further reading

- Kirby, Ian J. (1999). The complete dovetail: Handmade furniture's signature joint. Bethel, CT: Cambium Press. ISBN 9780964399990.

External links

| Wikimedia Commons has media related to Dovetail joints. |