Friction drive

A friction drive or friction engine is a type of transmission that utilises two wheels in the transmission to transfer power to the driving wheels rather than a chain and sprockets system. This kind of transmission is often used on scooters, mainly go-peds, in place of a chain. The problem with this type of drive system is they are not very efficient, since the output wheel (leather covered wheel) has width, the area of contact is spread across various radii on the primary disc. Because the tangential velocity varies as radius varies, the system must overcome velocity differentials across the surface. The compromise is slippage of the leather to metal contact area which creates friction, which in turn converts much of the energy transfer of this system into heat. Heat generation also requires a cooling system to keep the transmission working effectively.

In phonographs

Friction drive has been most successfully used in low-power applications, such as driving phonograph turntables.

In automobiles

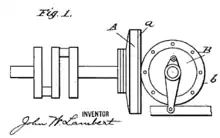

Automobiles using this drive system included the Anglo-Dane, the Arista, the Armadale, the Astra, the Allvelo, the Bukh & Gry, the Cartercar, the Crown 12HP Model Two (1905-1906), the Davis Totem, the Kelsey, the Lambert, the LuLu, the Metz, the Ner-a Car, the Richardson and the Turicum. The Turicum's friction drive consisted of a flat steel disk coupled directly to the engine. This primary disk subsequently drove a smaller leather covered wheel oriented normal to its surface. Assuming a constant rotational velocity on the primary wheel, the angular velocity on the disk's surface will increase proportionally to the distance from the center of rotation. Therefore, positioning the smaller wheel at different points along the larger wheel's surface varies the gear ratio. Furthermore, since there are no limitations beyond the minimum and maximum positions, the gear ratios are infinitely adjustable. The Lambert's friction drive (illustrated) was similar but used an aluminium-faced driving disk and a fiber-faced driven wheel.

In railway locomotives

Plymouth Locomotive Works's first three models, the AL, BL and CL were equipped with a friction drive.[1][2]

Early models of the permanent way maintenance ganger's Wickham trolley used a vee-twin JAP engine. This drove through a large flat flywheel and a friction drive.[3]

Belt drives

A belt drive is a form of friction drive but is usually categorized separately from the "disk and wheel" type of friction drive.

See also

- Contact mechanics – Study of the deformation of solids that touch each other

- Frictional contact mechanics – The study of the deformation of bodies in the presence of frictional effects

- Adhesion railway – Railway which relies on adhesion traction to move a train

- Rolling (metalworking) – Metal forming process

- Toroidal or roller-based CVT (Extroid CVT) – Automatic transmission that can change seamlessly through a continuous range of effective gear ratios

- Tribology – The science and engineering of interacting surfaces in relative motion

References

| Wikimedia Commons has media related to Friction drive. |

- Floyd B. Carter, Locomotive, U.S. Patent 1,283,665, Granted Nov. 5, 1918.

- Chas. A. Trask, Tractor Friction Transmissions, Journal of the Society of Automotive Engineers, Vol. II, No. 6 (June 1918); page 440. Page 444 discusses the Plymouth locomotive, with a drawing and photograph on page 445.

- "Wickham Motor Trolley". South Devon Railway. April 5, 2013.