Delabole wind farm

The Delabole wind farm was the first commercial onshore wind farm built in the United Kingdom, in November 1991.[1] This field of wind turbines was initially developed by Windelectric Management Ltd.

| Delabole wind farm | |

|---|---|

| |

| |

| Country | England |

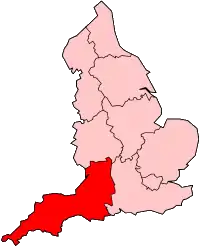

| Location | Cornwall |

| Coordinates | 50.633°N 4.708°W |

| Status | Operational |

| Commission date | 1991 |

| Operator(s) | Good Energy[1] |

| Power generation | |

| Units operational | 4 |

Location

Delabole is located in north Cornwall, England, UK, about two miles west of Camelford. It has the third highest elevation of the villages in Cornwall sitting at 800 feet making it an ideal place for turbines. The farm is pastoral land, one mile away from the village of Delabole and 2.5 miles away from the Celtic Sea. The country itself is the windiest of Europe receiving over 40% of the continent's wind annually.[2]

History

The farm was first proposed by landowners Peter and Martin Edwards in 1989, and was opened in 1991.[1][3][4] They chose to invest in the turbines, instead of a nuclear power plant, in the hope of pushing the UK in a greener direction. It took three months of construction to build the site and less than a month to commission the turbines. In its first year, the Delabole wind farm brought in 100,000 visitors who were able to look around the turbines freely on tourist walks.

Gaia Energy Centre

In 2001, there was an attempt to attract 150,000 tourists annually to this wind farm by building the Gaia Energy Centre. It was supposed to promote and educate the people of Cornwall about energy conservation and the benefits of renewable energy. Inside they had an auditorium, café and shop, as well as interactive exhibits and a resource library. Most of the funding for the £5 million Gaia Energy Centre came from Europe, with £300,000 grants from Objective One and the South West Regional Development Agency.[5] It closed down just three years after opening since less than a tenth of the projected visitors actually came.

New ownership

Although the Gaia Energy Centre was unsuccessful, the farm continued to stay in production. Since 2002, the farm has been owned and operated by Good Energy, whose goal is to make the UK 100% renewable by 2050. For its first two decades, it operated ten 400 kW WD34 wind turbines, built by Vestas.[3] In August 2010, these ten turbines were decommissioned to make way for better technology. In February 2011, an £11.8 million rebuilding of the facility was completed, which replaced the original ten with four new Enercon E-70 turbines standing at 98 meters, which are three times larger.[1][6] The funding came from a £9.6 million loan from the Co-operative bank and £2.2 million equity from Good Energy's own resources. After the rebuilding, the facility has a potential power output of 9.2 megawatts,[1][7] an increase from the original four megawatt output.[3]

In the beginning of 2013, Good Energy started offering a 20 percent discount on energy bills to the residents living within two miles of the wind farm. According to The Guardian, the projected savings is £110 annually, where the average national household payment is about £550.[8] Also, if the turbines produce more energy than expected, local customers can receive additional savings.

Turbines

The introduction of the German Enercon E-70 turbines prevent the release of 13,708 tons of carbon emissions into the atmosphere annually.[3] The amount of energy the new turbines produce is enough for over 7,800 homes, whereas the previous turbines only could provide energy for 2,700 homes.[1][6]

Vestas WD34 features

- 400 kW output

- Three blades sweeping a total area of 908 m2

- Tower height: 31 m

- Rotor diameter: 34 m

Enercon E-70 features

- Each turbine has a capacity of 2.3 megawatts

- Tower made of a steel tube and concrete

- Tower Height: 98 m

- Rotor Diameter: 71 m

- Gearless, with variable speeds ranging from 6-21 revolutions per minute (rpm) depending on the strength of the wind

- Each blade is adjustable

- An upwind rotor, in which the rotor is in front of the tower when the wind hits the turbine

- Three blades around the rotor made of GRP (epoxy resin) that move in the clockwise direction, sweeping a total area of 3,959 m2 turning the annular generator[9]

- The brake system of the turbine includes:

- Three independent pitch control systems with emergency power supply

- A rotor brake

- A rotor lock[9]

References

- "Chris Huhne reopens Cornwall's Delabole wind farm". BBC News Online. 22 February 2011. Retrieved 22 February 2011.

- "Wind". Good Energy. Good Energy LTD. 2014. Retrieved 7 November 2014.

- "Delabole". This is North Cornwall. Archived from the original on 22 February 2011. Retrieved 23 October 2014.

- "Briefing sheet Delabole wind farm, Cornwall" (PDF). Totnes community wind farm. Archived from the original (PDF) on 24 November 2014. Retrieved 24 October 2014.

- "UK | England | Cornwall | Energy tourist attraction shuts". BBC News. 30 September 2004. Retrieved 27 October 2014.

- "Delabole wind farm is redeveloped". BBC. 19 August 2010. Retrieved 5 March 2013.

- "Delabole Wind Farm Repower". Variable Pitch. 4 March 2013. Archived from the original on 5 May 2013. Retrieved 5 March 2013.

- "Residents near Cornwall windfarm to be offered energy bill discounts". The Guardian. theguardian.com. Retrieved 10 November 2014.

- "E-70 / 2,300 kW". Enercon. 2014. Retrieved 23 October 2014.