ISO metric screw thread

The ISO metric screw thread is the most commonly used type of general-purpose screw thread worldwide.[1] They were one of the first international standards agreed when the International Organization for Standardization (ISO) was set up in 1947.

The "M" designation for metric screws indicates the nominal outer diameter of the screw thread, in millimetres (e.g. an M6 screw has a nominal outer diameter of 6 millimetres).

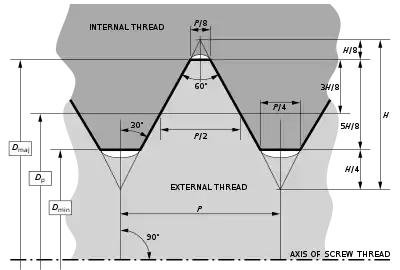

Basic profile

The design principles of ISO general-purpose metric screw threads ("M" series threads) are defined in international standard ISO 68-1.[2] Each thread is characterized by its major diameter, D (Dmaj in the diagram), and its pitch, P. ISO metric threads consist of a symmetric V-shaped thread. In the plane of the thread axis, the flanks of the V have an angle of 60° to each other. The thread depth is 0.54125 × pitch. The outermost 1⁄8 and the innermost 1⁄4 of the height H of the V-shape are cut off from the profile.

The relationship between the height H and the pitch P is found using the following equation where θ is half the included angle of the thread, in this case 30°:[3]

or

In an external (male) thread (e.g., on a bolt), the major diameter Dmaj and the minor diameter Dmin define maximum dimensions of the thread. This means that the external thread must end flat at Dmaj, but can be rounded out below the minor diameter Dmin. Conversely, in an internal (female) thread (e.g., in a nut), the major and minor diameters are minimum dimensions; therefore the thread profile must end flat at Dmin but may be rounded out beyond Dmaj.

The minor diameter Dmin and effective pitch diameter Dp are derived from the major diameter and pitch as

Designation

A metric ISO screw thread is designated by the letter M followed by the value of the nominal diameter D (the maximum thread diameter) and the pitch P, both expressed in millimetres and separated by the hyphen sign, - (e.g., M8-1.25). If the pitch is the normally used "coarse" pitch listed in ISO 261 or ISO 262, it can be omitted (e.g., M8). The length of a machine screw or bolt is indicated by a following x and the length expressed in millimetres (e.g., M8-1.25x30 or M8x30). Tolerance classes defined in ISO 965-1 can be appended to these designations, if required (e.g., M500– 6g in external threads).

External threads are designated by lowercase letter, g or h. Internal threads are designated by upper case letters, G or H.

Preferred sizes

ISO 261 specifies a detailed list of preferred combinations of outer diameter D and pitch P for ISO metric screw threads.[4][5] ISO 262 specifies a shorter list of thread dimensions – a subset of ISO 261.[6]

| Nominal diameter, D (mm) |

Series | Pitch, P (mm) |

Nominal diameter, D (mm) |

Series | Pitch, P (mm) | |||

|---|---|---|---|---|---|---|---|---|

| Coarse | Fine | Coarse | Fine | |||||

| 1 | R10 | 0.25 | 0.2 | ︙ | ||||

| 1.2 | R10 | 0.25 | 0.2 | 16 | R10 | 2 | 1.5 | |

| 1.4 | R20 | 0.3 | 0.2 | 18 | R20 | 2.5 | 2 or 1.5 | |

| 1.6 | R10 | 0.35 | 0.2 | 20 | R10 | 2.5 | 2 or 1.5 | |

| 1.8 | R20 | 0.35 | 0.2 | 22 | R20 | 2.5 | 2 or 1.5 | |

| 2 | R10 | 0.4 | 0.25 | 24 | R10 | 3 | 2 | |

| 2.5 | R10 | 0.45 | 0.35 | 27 | R20 | 3 | 2 | |

| 3 | R10 | 0.5 | 0.35 | 30 | R10 | 3.5 | 2 | |

| 3.5 | R20 | 0.6 | 0.35 | 33 | R20 | 3.5 | 2 | |

| 4 | R10 | 0.7 | 0.5 | 36 | R10 | 4 | 3 | |

| 5 | R10 | 0.8 | 0.5 | 39 | R20 | 4 | 3 | |

| 5.5[lower-alpha 1] | R20 | 0.9 | 0.5 | 42 | R10 | 4.5 | 3 | |

| 6 | R10 | 1 | 0.75 | 45 | R20 | 4.5 | 3 | |

| 7 | R20 | 1 | 0.75 | 48 | R10 | 5 | 3 | |

| 8 | R10 | 1.25 | 1 or 0.75 | 52 | R20 | 5 | 4 | |

| 10 | R10 | 1.5 | 1.25 or 1 | 56 | R10 | 5.5 | 4 | |

| 12 | R10 | 1.75 | 1.5 or 1.25 | 60 | R20 | 5.5 | 4 | |

| 14 | R20 | 2 | 1.5 | 64 | R10 | 6 | 4 | |

| ︙ | ||||||||

- Also DIN13[5]

The R10 series is from ISO 3, and the R20 series are rounded off values from ISO 3.[4]

The coarse pitch is the commonly used default pitch for a given diameter. In addition, one or two smaller fine pitches are defined, for use in applications where the height of the normal coarse pitch would be unsuitable (e.g., threads in thin-walled pipes). The terms coarse and fine have (in this context) no relation to the manufacturing quality of the thread.

In addition to coarse and fine threads, there is another division of extra fine, or superfine threads, with a very fine pitch thread. Superfine pitch metric threads are occasionally used in automotive components, such as suspension struts, and are commonly used in the aviation manufacturing industry. This is because extra fine threads are more resistant to coming loose from vibrations.[7] Fine and superfine threads also have a greater minor diameter than coarse threads, which means the bolt or stud has a greater cross-sectional area (and therefore greater load-carrying capability) for the same nominal diameter.

Spanner (wrench) sizes

Below are some common spanner (wrench) sizes for metric screw threads. Hex head widths (width across flats, spanner size) are for DIN 934 hex nuts and hex head bolts. Other (usually smaller) sizes may occur for reasons of weight and cost reduction.

Thread |

Spanner (wrench) size (mm) | ||||

|---|---|---|---|---|---|

Hex nut, and bolt |

Socket-head cap screw |

|

Set, or grub, screw | ||

| ISO | DIN | ||||

| M1 | - | 2.5 | - | - | - |

| M1.2 | - | 3 | - | - | - |

| M1.4 | - | 3 | 1.25 | - | 0.7 |

| M1.6 | 3.2 | 1.5 | 0.9 | 0.7 | |

| M2 | 4 | 1.5 | 1.25 | 0.9 | |

| M2.5 | 5 | 2 | 1.5 | 1.3 | |

| M3 | 5.5 | 2.5 | 2 | 1.5 | |

| M3.5 | 6 | - | - | - | |

| M4 | 7 | 3 | 2.5 | 2 | |

| M5 | 8 | 4 | 3 | 2.5 | |

| M6 | 10 | 5 | 4 | 3 | |

| M7 | 11 | - | - | - | |

| M8 | 13 | 6 | 5 | 4 | |

| M10 | 16 | 17 | 8 | 6 | 5 |

| M12 | 18 | 19 | 10 | 8 | 6 |

| M14 | 21 | 22 | 10 | - | - |

| M16 | 24 | 14 | 10 | 8 | |

| M18 | 27 | 14 | 12 | - | |

| M20 | 30 | 17 | 12 | 10 | |

| M22 | 34 | 32 | 17 | 14 | - |

| M24 | 36 | 19 | 14 | 12 | |

| M27 | 41 | 19 | 17 | 14 | |

| M30 | 46 | 22 | 17 | 14 | |

| M33 | 50 | 24 | - | - | |

| M36 | 55 | 27 | - | - | |

| M39 | 60 | - | - | - | |

| M42 | 65 | 32 | - | - | |

| M45 | 70 | - | - | - | |

| M48 | 75 | 36 | - | - | |

| M52 | 80 | 36 | - | - | |

| M56 | 85 | 41 | - | - | |

| M60 | 90 | - | - | - | |

| M64 | 95 | 46 | - | - | |

Standards

International

- ISO 68-1: ISO general purpose screw threads — Basic profile — Metric screw threads.

- ISO 261: ISO general purpose metric screw threads — General plan.

- ISO 262: ISO general purpose metric screw threads — Selected sizes for screws, bolts and nuts.

- ISO 965: ISO general purpose metric screw threads — Tolerances[8]

- ISO 965-1: Principles and basic data

- ISO 965-2: Limits of sizes for general purpose external and internal screw threads.

- ISO 965-3: Deviations for constructional screw threads

- ISO 965-4: Limits of sizes for hot-dip galvanized external screw threads to mate with internal screw threads tapped with tolerance position H or G after galvanizing

- ISO 965-5: Limits of sizes for internal screw threads to mate with hot-dip galvanized external screw threads with maximum size of tolerance position h before galvanizing

National

- BS 3643: ISO metric screw threads

- ANSI/ASME B1.13M: Metric Screw Threads: M Profile

- ANSI/ASME B4.2-1978 (R2009): Preferred Metric Limits and Fits

- Page 519 DIN13

See also

- ASTM A325M

- ASTM F568M

- British Association screw threads (BA)

- British Standard Cycle (BSC)

- British standard fine thread (BSF)

- British standard pipe thread (BSP)

- British Standard Whitworth (BSW) – a British thread standard with 55° profile.

- Buttress thread

- Engineering tolerance

- Garden hose thread

- List of drill and tap sizes

- National pipe thread (NPT)

- National thread

- Nominal size

- Panzergewinde

- Photographic Filter thread

- Preferred metric sizes

- Screw thread

- Square thread form

- Thread angle

- Trapezoidal thread forms

- United States Standard thread

- Unified Thread Standard (UTS, UNC, UNF, UNEF and UNS) – a US/Canadian/British thread standard that uses the same 60° profile as metric threads, but an inch-based set of diameter/pitch combinations.

References

- ISO/TC/ 1 Business Plan, 2007-03-05, Version 1.3. Table 3: The market share of each screw thread, p. 7.

- ISO 68-1:1998 ISO general purpose screw threads – Basic profile – Part 1: Metric screw threads. International Organization for Standardization.

- Oberg et al. 2000, p. 1706

- ISO 261:1998 ISO general purpose metric screw threads – General plan. International Organization for Standardization. 17 Dec 1998.

- ISO & DIN13

- ISO 262:1998 ISO general purpose metric screw threads – Selected sizes for screws, bolts and nuts. International Organization for Standardization. 17 Dec 1998.

- "Final report" (PDF). ntrs.nasa.gov.

- ISO 965 in the Catalogue on the Official ISO website

Bibliography

- Oberg, Erik; Jones, Franklin D.; Horton, Holbrook L.; Ryffel, Henry H. (2000), Machinery's Handbook (26th ed.), New York: Industrial Press Inc., ISBN 0-8311-2635-3.