Flash memory

Flash memory is an electronic non-volatile computer memory storage medium that can be electrically erased and reprogrammed. The two main types of flash memory, NOR flash and NAND flash, are named after the NOR and NAND logic gates. Both NAND flash and NOR flash use the same cell design, consisting of floating gate MOSFETs. They differ on the circuit level, NAND flash is called such because the relationship between the bit line and the word lines resemble a NAND gate, while on NOR flash they resemble a NOR gate. This is in regards to the state of the bit line or word lines being pulled high or low.

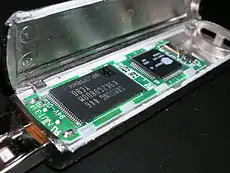

Flash memory is a type of floating-gate memory that was invented at Toshiba in 1980, based on EEPROM technology. Toshiba commercially introduced flash memory to the market in 1987.[1] While EPROMs had to be completely erased before being rewritten, NAND-type flash memory may be erased, written and read in blocks (or pages) which are generally much smaller than the entire device. NOR-type flash allows a single machine word to be written – to an erased location – or read independently. A flash memory device typically consists of one or more flash memory chips (each holding many flash memory cells) along with a separate flash memory controller chip.

The NAND type is found primarily in memory cards, USB flash drives, solid-state drives (those produced in 2009 or later), feature phones, smartphones and similar products, for general storage and transfer of data. NAND or NOR flash memory is also often used to store configuration data in numerous digital products, a task previously made possible by EEPROM or battery-powered static RAM. One key disadvantage of flash memory is that it can only endure a relatively small number of write cycles in a specific block.[2]

Example applications of flash memory include computers, PDAs, digital audio players, digital cameras, mobile phones, synthesizers, video games, scientific instrumentation, industrial robotics, and medical electronics. In addition to being non-volatile, flash memory offers fast read access times, although not as fast as static RAM or ROM.[3] Its mechanical shock resistance helps explain its popularity over hard disks in portable devices.

Because erase cycles are slow, the large block sizes used in flash memory erasing give it a significant speed advantage over non-flash EEPROM when writing large amounts of data. As of 2019, flash memory costs much less than byte-programmable EEPROM and had become the dominant memory type wherever a system required a significant amount of non-volatile solid-state storage. EEPROMs, however, are still used on applications that only require small amounts of storage, like in serial presence detect.[4][5]

Flash memory packages can use die stacking with through-silicon vias and several dozen layers of 3D TLC NAND cells (per die) simultaneously to achieve capacities of up to 1 tebibyte per package using 16 stacked dies and an integrated flash controller as a separate die inside the package.[6][7][8][9]

History

Background

The origins of flash memory can be traced back to the development of the floating-gate MOSFET (FGMOS), also known as the floating-gate transistor.[10][11] The original MOSFET (metal–oxide–semiconductor field-effect transistor), also known as the MOS transistor, was invented by Egyptian engineer Mohamed M. Atalla and Korean engineer Dawon Kahng at Bell Labs in 1959.[12] Kahng went on to develop a variation, the floating-gate MOSFET, with Chinese engineer Simon Min Sze at Bell Labs in 1967.[13] They proposed that it could be used as floating-gate memory cells for storing a form of programmable read-only memory (PROM) that is both non-volatile and re-programmable.[13]

Early types of floating-gate memory included EPROM (erasable PROM) and EEPROM (electrically erasable PROM) in the 1970s.[13] However, early floating-gate memory required engineers to build a memory cell for each bit of data, which proved to be cumbersome,[14] slow,[15] and expensive, restricting floating-gate memory to niche applications in the 1970s, such as military equipment and the earliest experimental mobile phones.[10]

Invention and commercialization

Fujio Masuoka, while working for Toshiba, proposed a new type of floating-gate memory that allowed entire sections of memory to be erased quickly and easily, by applying a voltage to a single wire connected to a group of cells.[10] This led to Masuoka's invention of flash memory at Toshiba in 1980.[14][16][17] According to Toshiba, the name "flash" was suggested by Masuoka's colleague, Shōji Ariizumi, because the erasure process of the memory contents reminded him of the flash of a camera.[18] Masuoka and colleagues presented the invention of NOR flash in 1984,[19][20] and then NAND flash at the IEEE 1987 International Electron Devices Meeting (IEDM) held in San Francisco.[21]

Toshiba commercially launched NAND flash memory in 1987.[1][13] Intel Corporation introduced the first commercial NOR type flash chip in 1988.[22] NOR-based flash has long erase and write times, but provides full address and data buses, allowing random access to any memory location. This makes it a suitable replacement for older read-only memory (ROM) chips, which are used to store program code that rarely needs to be updated, such as a computer's BIOS or the firmware of set-top boxes. Its endurance may be from as little as 100 erase cycles for an on-chip flash memory,[23] to a more typical 10,000 or 100,000 erase cycles, up to 1,000,000 erase cycles.[24] NOR-based flash was the basis of early flash-based removable media; CompactFlash was originally based on it, though later cards moved to less expensive NAND flash.

NAND flash has reduced erase and write times, and requires less chip area per cell, thus allowing greater storage density and lower cost per bit than NOR flash. However, the I/O interface of NAND flash does not provide a random-access external address bus. Rather, data must be read on a block-wise basis, with typical block sizes of hundreds to thousands of bits. This makes NAND flash unsuitable as a drop-in replacement for program ROM, since most microprocessors and microcontrollers require byte-level random access. In this regard, NAND flash is similar to other secondary data storage devices, such as hard disks and optical media, and is thus highly suitable for use in mass-storage devices, such as memory cards and solid-state drives (SSD). Flash memory cards and SSDs store data using multiple NAND flash memory chips.

The first NAND-based removable memory card format was SmartMedia, released in 1995. Many others followed, including MultiMediaCard, Secure Digital, Memory Stick, and xD-Picture Card.

Later developments

A new generation of memory card formats, including RS-MMC, miniSD and microSD, feature extremely small form factors. For example, the microSD card has an area of just over 1.5 cm2, with a thickness of less than 1 mm.

NAND flash has achieved significant levels of memory density as a result of several major technologies that were commercialized during the late 2000s to early 2010s.[25]

Multi-level cell (MLC) technology stores more than one bit in each memory cell. NEC demonstrated multi-level cell (MLC) technology in 1998, with an 80 Mb flash memory chip storing 2 bits per cell.[26] STMicroelectronics also demonstrated MLC in 2000, with a 64 Mbb NOR flash memory chip.[27] In 2009, Toshiba and SanDisk introduced NAND flash chips with QLC technology storing 4-bit per cell and holding a capacity of 64 Gbit.[28][29] Samsung Electronics introduced triple-level cell (TLC) technology storing 3-bits per cell, and began mass-producing NAND chips with TLC technology in 2010.[30]

Charge trap flash

Charge trap flash (CTF) technology was first disclosed in 1967 by John Szedon and Ting L. Chu but was not used for flash memory production until 2002.

CTF technology replaces the polysilicon floating gate, which is sandwiched between a blocking gate oxide above and a tunneling oxide below it, with an electrically insulating silicon nitride layer; the silicon nitride layer traps electrons. In theory, CTF is less prone to electron leakage, providing improved data retention.[31][32][33][34][35][36]

Because CTF replaces the polysilicon with an electrically insulating nitride, it allows for smaller cells and higher endurance (lower degradation or wear). However, electrons can become trapped and accumulate in the nitride, leading to degradation, Leakage is exacerbated at high temperatures since electrons become more excitated with increasing temperatures. CTF technology however still uses a tunneling oxide and blocking layer which are the weak points of the technology, since they can still be damaged in the usual ways (the tunnel oxide can be degraded due to extremely high voltage densities and the blocking layer due to Anode Hot Hole Injection (AHHI).[37][38]

Degradation or wear of the oxides is the reason why flash memory has limited endurance, and data retention goes down (the potential for data loss increases) with increasing degradation, since the oxides lose their electrically insulating characteristics as they degrade. The oxides must insulate against electrons to prevent them from leaking which would cause data loss.

In 1991, NEC researchers including N. Kodama, K. Oyama and Hiroki Shirai described a type of flash memory with a charge trap method.[39] In 1998, Boaz Eitan of Saifun Semiconductors (later acquired by Spansion) patented a flash memory technology named NROM that took advantage of a charge trapping layer to replace the conventional floating gate used in conventional flash memory designs.[40] In 2000, an Advanced Micro Devices (AMD) research team led by Richard M. Fastow, Egyptian engineer Khaled Z. Ahmed and Jordanian engineer Sameer Haddad (who later joined Spansion) demonstrated a charge-trapping mechanism for NOR flash memory cells.[41] CTF was later commercialized by AMD and Fujitsu in 2002.[42] 3D V-NAND (vertical NAND) technology stacks NAND flash memory cells vertically within a chip using 3D charge trap flash (CTP) technology. 3D V-NAND technology was first announced by Toshiba in 2007,[43] and the first device, with 24 layers, was first commercialized by Samsung Electronics in 2013.[44][45]

3D integrated circuit technology

3D integrated circuit (3D IC) technology stacks integrated circuit (IC) chips vertically into a single 3D IC chip package.[25] Toshiba introduced 3D IC technology to NAND flash memory in April 2007, when they debuted a 16 GB THGAM embedded NAND flash memory chip, which was manufactured with eight stacked 2 GB NAND flash chips.[46] In September 2007, Hynix Semiconductor (now SK Hynix) introduced 24-layer 3D IC technology, with a 16 GB flash memory chip that was manufactured with 24 stacked NAND flash chips using a wafer bonding process.[47] Toshiba also used an eight-layer 3D IC for their 32 GB THGBM flash chip in 2008.[48] In 2010, Toshiba used a 16-layer 3D IC for their 128 GB THGBM2 flash chip, which was manufactured with 16 stacked 8 GB chips.[49] In the 2010s, 3D ICs came into widespread commercial use for NAND flash memory in mobile devices.[25]

As of August 2017, microSD cards with a capacity up to 400 GB (400 billion bytes) are available.[50][51] The same year, Samsung combined 3D IC chip stacking with its 3D V-NAND and TLC technologies to manufacture its 512 GB KLUFG8R1EM flash memory chip with eight stacked 64-layer V-NAND chips.[52] In 2019, Samsung produced a 1024 GB flash chip, with eight stacked 96-layer V-NAND chips and with QLC technology.[53][54]

Principles of operation

Flash memory stores information in an array of memory cells made from floating-gate transistors. In single-level cell (SLC) devices, each cell stores only one bit of information. Multi-level cell (MLC) devices, including triple-level cell (TLC) devices, can store more than one bit per cell.

The floating gate may be conductive (typically polysilicon in most kinds of flash memory) or non-conductive (as in SONOS flash memory).[55]

Floating-gate MOSFET

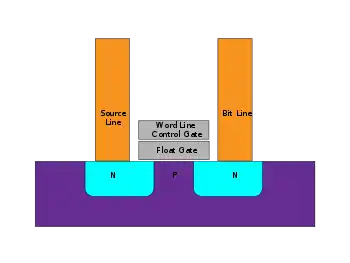

In flash memory, each memory cell resembles a standard metal–oxide–semiconductor field-effect transistor (MOSFET) except that the transistor has two gates instead of one. The cells can be seen as an electrical switch in which current flows between two terminals (source and drain) and is controlled by a floating gate (FG) and a control gate (CG). The CG is similar to the gate in other MOS transistors, but below this, there is the FG insulated all around by an oxide layer. The FG is interposed between the CG and the MOSFET channel. Because the FG is electrically isolated by its insulating layer, electrons placed on it are trapped. When the FG is charged with electrons, this charge screens the electric field from the CG, thus, increasing the threshold voltage (VT1) of the cell. This means that now a higher voltage (VT2) must be applied to the CG to make the channel conductive. In order to read a value from the transistor, an intermediate voltage between the threshold voltages (VT1 & VT2) is applied to the CG. If the channel conducts at this intermediate voltage, the FG must be uncharged (if it was charged, we would not get conduction because the intermediate voltage is less than VT2), and hence, a logical "1" is stored in the gate. If the channel does not conduct at the intermediate voltage, it indicates that the FG is charged, and hence, a logical "0" is stored in the gate. The presence of a logical "0" or "1" is sensed by determining whether there is current flowing through the transistor when the intermediate voltage is asserted on the CG. In a multi-level cell device, which stores more than one bit per cell, the amount of current flow is sensed (rather than simply its presence or absence), in order to determine more precisely the level of charge on the FG.

Floating gate MOSFETs are so named because there is an electrically insulating tunnel oxide layer between the gate and the silicon, so the gate "floats" above the silicon. The oxide keeps the electrons confined to the floating gate. Degradation or wear (and the limited endurance of floating gate Flash memory) occurs due to the extremely high electric field (10 million volts per centimeter) experienced by the oxide. Such high voltage densities can break atomic bonds over time in the relatively thin oxide, gradually degrading its electrically insulating properties and allowing electrons to be trapped in and pass through freely (leak) from the floating gate into the oxide, increasing the likelihood of data loss since the electrons (the quantity of which is used to represent different charge levels, each assigned to a different combination of bits in MLC Flash) are normally in the floating gate. This is why data retention goes down and the risk of data loss increases with increasing degradation.[56][57][58][59][60]

Fowler–Nordheim tunneling

The process of moving electrons from the control gate and into the floating gate is called Fowler–Nordheim tunneling, and it fundamentally changes the characteristics of the cell by increasing the MOSFET's threshold voltage. This, in turn, changes the drain-source current that flows through the transistor for a given gate voltage, which is ultimately used to encode a binary value. The Fowler-Nordheim tunneling effect is reversible, so electrons can be added to or removed from the floating gate, processes traditionally known as writing and erasing.[61]

Internal charge pumps

Despite the need for relatively high programming and erasing voltages, virtually all flash chips today require only a single supply voltage and produce the high voltages that are required using on-chip charge pumps.

Over half the energy used by a 1.8 V NAND flash chip is lost in the charge pump itself. Since boost converters are inherently more efficient than charge pumps, researchers developing low-power SSDs have proposed returning to the dual Vcc/Vpp supply voltages used on all early flash chips, driving the high Vpp voltage for all flash chips in an SSD with a single shared external boost converter.[62][63][64][65][66][67][68][69]

In spacecraft and other high-radiation environments, the on-chip charge pump is the first part of the flash chip to fail, although flash memories will continue to work – in read-only mode – at much higher radiation levels.[70]

NOR flash

In NOR flash, each cell has one end connected directly to ground, and the other end connected directly to a bit line. This arrangement is called "NOR flash" because it acts like a NOR gate: when one of the word lines (connected to the cell's CG) is brought high, the corresponding storage transistor acts to pull the output bit line low. NOR flash continues to be the technology of choice for embedded applications requiring a discrete non-volatile memory device. The low read latencies characteristic of NOR devices allow for both direct code execution and data storage in a single memory product.[71]

Programming

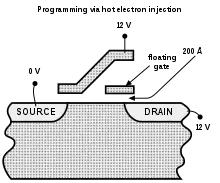

A single-level NOR flash cell in its default state is logically equivalent to a binary "1" value, because current will flow through the channel under application of an appropriate voltage to the control gate, so that the bitline voltage is pulled down. A NOR flash cell can be programmed, or set to a binary "0" value, by the following procedure:

- an elevated on-voltage (typically >5 V) is applied to the CG

- the channel is now turned on, so electrons can flow from the source to the drain (assuming an NMOS transistor)

- the source-drain current is sufficiently high to cause some high energy electrons to jump through the insulating layer onto the FG, via a process called hot-electron injection.

Erasing

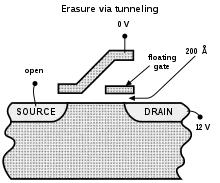

To erase a NOR flash cell (resetting it to the "1" state), a large voltage of the opposite polarity is applied between the CG and source terminal, pulling the electrons off the FG through quantum tunneling. Modern NOR flash memory chips are divided into erase segments (often called blocks or sectors). The erase operation can be performed only on a block-wise basis; all the cells in an erase segment must be erased together. Programming of NOR cells, however, generally can be performed one byte or word at a time.

NAND flash

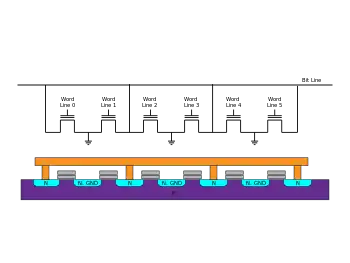

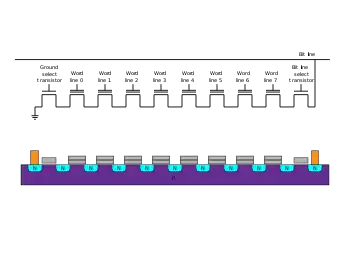

NAND flash also uses floating-gate transistors, but they are connected in a way that resembles a NAND gate: several transistors are connected in series, and the bit line is pulled low only if all the word lines are pulled high (above the transistors' VT). These groups are then connected via some additional transistors to a NOR-style bit line array in the same way that single transistors are linked in NOR flash.

Compared to NOR flash, replacing single transistors with serial-linked groups adds an extra level of addressing. Whereas NOR flash might address memory by page then word, NAND flash might address it by page, word and bit. Bit-level addressing suits bit-serial applications (such as hard disk emulation), which access only one bit at a time. Execute-in-place applications, on the other hand, require every bit in a word to be accessed simultaneously. This requires word-level addressing. In any case, both bit and word addressing modes are possible with either NOR or NAND flash.

To read data, first the desired group is selected (in the same way that a single transistor is selected from a NOR array). Next, most of the word lines are pulled up above the VT of a programmed bit, while one of them is pulled up to just over the VT of an erased bit. The series group will conduct (and pull the bit line low) if the selected bit has not been programmed.

Despite the additional transistors, the reduction in ground wires and bit lines allows a denser layout and greater storage capacity per chip. (The ground wires and bit lines are actually much wider than the lines in the diagrams.) In addition, NAND flash is typically permitted to contain a certain number of faults (NOR flash, as is used for a BIOS ROM, is expected to be fault-free). Manufacturers try to maximize the amount of usable storage by shrinking the size of the transistors.

NAND Flash cells are read by analysing their response to various voltages. [59]

Writing and erasing

NAND flash uses tunnel injection for writing and tunnel release for erasing. NAND flash memory forms the core of the removable USB storage devices known as USB flash drives, as well as most memory card formats and solid-state drives available today.

The hierarchical structure of NAND Flash starts at a cell level which establishes strings, then pages, blocks, planes and ultimately a die. A string is a series of connected NAND cells in which the source of one cell is connected to the drain of the next one. Depending on the NAND technology, a string typically consists of 32 to 128 NAND cells. Strings are organised into pages which are then organised into blocks in which each string is connected to a separate line called a bitline (BL) All cells with the same position in the string are connected through the control gates by a wordline (WL) A plane contains a certain number of blocks that are connected through the same BL. A Flash die consists of one or more planes, and the peripheral circuitry that is needed to perform all the read/ write/ erase operations.

The architecture of NAND Flash means that data can be read and programmed in pages, typically between 4 KiB and 16 KiB in size, but can only be erased at the level of entire blocks consisting of multiple pages and MB in size. When a block is erased all the cells are logically set to 1. Data can only be programmed in one pass to a page in a block that was erased. Any cells that have been set to 0 by programming can only be reset to 1 by erasing the entire block. This means that before new data can be programmed into a page that already contains data, the current contents of the page plus the new data must be copied to a new, erased page. If a suitable page is available, the data can be written to it immediately. If no erased page is available, a block must be erased before copying the data to a page in that block. The old page is then marked as invalid and is available for erasing and reuse.[72]

Vertical NAND

Vertical NAND (V-NAND) or 3D NAND memory stacks memory cells vertically and uses a charge trap flash architecture. The vertical layers allow larger areal bit densities without requiring smaller individual cells.[73] It is also sold under the trademark BiCS Flash, which is a trademark of Kioxia Corporation (former Toshiba Memory Corporation). 3D NAND was first announced by Toshiba in 2007.[43] V-NAND was first commercially manufactured by Samsung Electronics in 2013.[44][45][74][75]

Structure

V-NAND uses a charge trap flash geometry (which was commercially introduced in 2002 by AMD and Fujitsu)[42] that stores charge on an embedded silicon nitride film. Such a film is more robust against point defects and can be made thicker to hold larger numbers of electrons. V-NAND wraps a planar charge trap cell into a cylindrical form.[73] As of 2020, 3D NAND Flash memories by Micron and Intel instead use floating gates, however, Micron 128 layer and above 3D NAND memories use a conventional charge trap structure, due to the dissolution of the partnership between Micron and Intel. Charge trap 3D NAND Flash is thinner than floating gate 3D NAND. In floating gate 3D NAND, the memory cells are completely separated from one another, whereas in charge trap 3D NAND, vertical groups of memory cells share the same silicon nitride material.[76]

An individual memory cell is made up of one planar polysilicon layer containing a hole filled by multiple concentric vertical cylinders. The hole's polysilicon surface acts as the gate electrode. The outermost silicon dioxide cylinder acts as the gate dielectric, enclosing a silicon nitride cylinder that stores charge, in turn enclosing a silicon dioxide cylinder as the tunnel dielectric that surrounds a central rod of conducting polysilicon which acts as the conducting channel.[73]

Memory cells in different vertical layers do not interfere with each other, as the charges cannot move vertically through the silicon nitride storage medium, and the electric fields associated with the gates are closely confined within each layer. The vertical collection is electrically identical to the serial-linked groups in which conventional NAND flash memory is configured.[73]

Construction

Growth of a group of V-NAND cells begins with an alternating stack of conducting (doped) polysilicon layers and insulating silicon dioxide layers.[73]

The next step is to form a cylindrical hole through these layers. In practice, a 128 Gibit V-NAND chip with 24 layers of memory cells requires about 2.9 billion such holes. Next, the hole's inner surface receives multiple coatings, first silicon dioxide, then silicon nitride, then a second layer of silicon dioxide. Finally, the hole is filled with conducting (doped) polysilicon.[73]

Performance

As of 2013, V-NAND flash architecture allows read and write operations twice as fast as conventional NAND and can last up to 10 times as long, while consuming 50 percent less power. They offer comparable physical bit density using 10-nm lithography but may be able to increase bit density by up to two orders of magnitude, given V-NAND's use of up to several hundred layers.[73] As of 2020, V-NAND chips with 160 layers are under development by Samsung.[77]

Cost

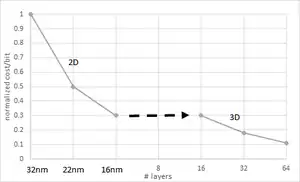

The wafer cost of a 3D NAND is comparable with scaled down (32 nm or less) planar NAND Flash.[78] However, with planar NAND scaling stopping at 16 nm, the cost per bit reduction can continue by 3D NAND starting with 16 layers.

Limitations

Block erasure

One limitation of flash memory is that, although it can be read or programmed a byte or a word at a time in a random access fashion, it can be erased only a block at a time. This generally sets all bits in the block to 1. Starting with a freshly erased block, any location within that block can be programmed. However, once a bit has been set to 0, only by erasing the entire block can it be changed back to 1. In other words, flash memory (specifically NOR flash) offers random-access read and programming operations but does not offer arbitrary random-access rewrite or erase operations. A location can, however, be rewritten as long as the new value's 0 bits are a superset of the over-written values. For example, a nibble value may be erased to 1111, then written as 1110. Successive writes to that nibble can change it to 1010, then 0010, and finally 0000. Essentially, erasure sets all bits to 1, and programming can only clear bits to 0.[79] Some file systems designed for flash devices make use of this rewrite capability, for example Yaffs1, to represent sector metadata. Other flash file systems, such as YAFFS2, never make use of this "rewrite" capability—they do a lot of extra work to meet a "write once rule".

Although data structures in flash memory cannot be updated in completely general ways, this allows members to be "removed" by marking them as invalid. This technique may need to be modified for multi-level cell devices, where one memory cell holds more than one bit.

Common flash devices such as USB flash drives and memory cards provide only a block-level interface, or flash translation layer (FTL), which writes to a different cell each time to wear-level the device. This prevents incremental writing within a block; however, it does help the device from being prematurely worn out by intensive write patterns.

Memory wear

Another limitation is that flash memory has a finite number of program – erase cycles (typically written as P/E cycles). Most commercially available flash products are guaranteed to withstand around 100,000 P/E cycles before the wear begins to deteriorate the integrity of the storage.[80] Micron Technology and Sun Microsystems announced an SLC NAND flash memory chip rated for 1,000,000 P/E cycles on 17 December 2008.[81]

The guaranteed cycle count may apply only to block zero (as is the case with TSOP NAND devices), or to all blocks (as in NOR). This effect is mitigated in some chip firmware or file system drivers by counting the writes and dynamically remapping blocks in order to spread write operations between sectors; this technique is called wear leveling. Another approach is to perform write verification and remapping to spare sectors in case of write failure, a technique called bad block management (BBM). For portable consumer devices, these wear out management techniques typically extend the life of the flash memory beyond the life of the device itself, and some data loss may be acceptable in these applications. For high-reliability data storage, however, it is not advisable to use flash memory that would have to go through a large number of programming cycles. This limitation is meaningless for 'read-only' applications such as thin clients and routers, which are programmed only once or at most a few times during their lifetimes.

In December 2012, Taiwanese engineers from Macronix revealed their intention to announce at the 2012 IEEE International Electron Devices Meeting that they had figured out how to improve NAND flash storage read/write cycles from 10,000 to 100 million cycles using a "self-healing" process that used a flash chip with "onboard heaters that could anneal small groups of memory cells."[82] The built-in thermal annealing was to replace the usual erase cycle with a local high temperature process that not only erased the stored charge, but also repaired the electron-induced stress in the chip, giving write cycles of at least 100 million.[83] The result was to be a chip that could be erased and rewritten over and over, even when it should theoretically break down. As promising as Macronix's breakthrough might have been for the mobile industry, however, there were no plans for a commercial product to be released any time in the near future.[84]

Read disturb

The method used to read NAND flash memory can cause nearby cells in the same memory block to change over time (become programmed). This is known as read disturb. The threshold number of reads is generally in the hundreds of thousands of reads between intervening erase operations. If reading continually from one cell, that cell will not fail but rather one of the surrounding cells on a subsequent read. To avoid the read disturb problem the flash controller will typically count the total number of reads to a block since the last erase. When the count exceeds a target limit, the affected block is copied over to a new block, erased, then released to the block pool. The original block is as good as new after the erase. If the flash controller does not intervene in time, however, a read disturb error will occur with possible data loss if the errors are too numerous to correct with an error-correcting code.[85][86][87]

X-ray effects

Most flash ICs come in ball grid array (BGA) packages, and even the ones that do not are often mounted on a PCB next to other BGA packages. After PCB Assembly, boards with BGA packages are often X-rayed to see if the balls are making proper connections to the proper pad, or if the BGA needs rework. These X-rays can erase programmed bits in a flash chip (convert programmed "0" bits into erased "1" bits). Erased bits ("1" bits) are not affected by X-rays.[88][89]

Some manufacturers are now making X-ray proof SD[90] and USB[91] memory devices.

Low-level access

The low-level interface to flash memory chips differs from those of other memory types such as DRAM, ROM, and EEPROM, which support bit-alterability (both zero to one and one to zero) and random access via externally accessible address buses.

NOR memory has an external address bus for reading and programming. For NOR memory, reading and programming are random-access, and unlocking and erasing are block-wise. For NAND memory, reading and programming are page-wise, and unlocking and erasing are block-wise.

NOR memories

Reading from NOR flash is similar to reading from random-access memory, provided the address and data bus are mapped correctly. Because of this, most microprocessors can use NOR flash memory as execute in place (XIP) memory, meaning that programs stored in NOR flash can be executed directly from the NOR flash without needing to be copied into RAM first. NOR flash may be programmed in a random-access manner similar to reading. Programming changes bits from a logical one to a zero. Bits that are already zero are left unchanged. Erasure must happen a block at a time, and resets all the bits in the erased block back to one. Typical block sizes are 64, 128, or 256 KiB.

Bad block management is a relatively new feature in NOR chips. In older NOR devices not supporting bad block management, the software or device driver controlling the memory chip must correct for blocks that wear out, or the device will cease to work reliably.

The specific commands used to lock, unlock, program, or erase NOR memories differ for each manufacturer. To avoid needing unique driver software for every device made, special Common Flash Memory Interface (CFI) commands allow the device to identify itself and its critical operating parameters.

Besides its use as random-access ROM, NOR flash can also be used as a storage device, by taking advantage of random-access programming. Some devices offer read-while-write functionality so that code continues to execute even while a program or erase operation is occurring in the background. For sequential data writes, NOR flash chips typically have slow write speeds, compared with NAND flash.

Typical NOR flash does not need an error correcting code.[92]

NAND memories

NAND flash architecture was introduced by Toshiba in 1989.[93] These memories are accessed much like block devices, such as hard disks. Each block consists of a number of pages. The pages are typically 512,[94] 2,048 or 4,096 bytes in size. Associated with each page are a few bytes (typically 1/32 of the data size) that can be used for storage of an error correcting code (ECC) checksum.

Typical block sizes include:

- 32 pages of 512+16 bytes each for a block size (effective) of 16 KiB

- 64 pages of 2,048+64 bytes each for a block size of 128 KiB[95]

- 64 pages of 4,096+128 bytes each for a block size of 256 KiB[96]

- 128 pages of 4,096+128 bytes each for a block size of 512 KiB.

While reading and programming is performed on a page basis, erasure can only be performed on a block basis.[97]

NAND devices also require bad block management by the device driver software or by a separate controller chip. SD cards, for example, include controller circuitry to perform bad block management and wear leveling. When a logical block is accessed by high-level software, it is mapped to a physical block by the device driver or controller. A number of blocks on the flash chip may be set aside for storing mapping tables to deal with bad blocks, or the system may simply check each block at power-up to create a bad block map in RAM. The overall memory capacity gradually shrinks as more blocks are marked as bad.

NAND relies on ECC to compensate for bits that may spontaneously fail during normal device operation. A typical ECC will correct a one-bit error in each 2048 bits (256 bytes) using 22 bits of ECC, or a one-bit error in each 4096 bits (512 bytes) using 24 bits of ECC.[98] If the ECC cannot correct the error during read, it may still detect the error. When doing erase or program operations, the device can detect blocks that fail to program or erase and mark them bad. The data is then written to a different, good block, and the bad block map is updated.

Hamming codes are the most commonly used ECC for SLC NAND flash. Reed-Solomon codes and BCH codes (Bose-Chaudhuri-Hocquenghem codes) are commonly used ECC for MLC NAND flash. Some MLC NAND flash chips internally generate the appropriate BCH error correction codes.[92]

Most NAND devices are shipped from the factory with some bad blocks. These are typically marked according to a specified bad block marking strategy. By allowing some bad blocks, manufacturers achieve far higher yields than would be possible if all blocks had to be verified to be good. This significantly reduces NAND flash costs and only slightly decreases the storage capacity of the parts.

When executing software from NAND memories, virtual memory strategies are often used: memory contents must first be paged or copied into memory-mapped RAM and executed there (leading to the common combination of NAND + RAM). A memory management unit (MMU) in the system is helpful, but this can also be accomplished with overlays. For this reason, some systems will use a combination of NOR and NAND memories, where a smaller NOR memory is used as software ROM and a larger NAND memory is partitioned with a file system for use as a non-volatile data storage area.

NAND sacrifices the random-access and execute-in-place advantages of NOR. NAND is best suited to systems requiring high capacity data storage. It offers higher densities, larger capacities, and lower cost. It has faster erases, sequential writes, and sequential reads.

Standardization

A group called the Open NAND Flash Interface Working Group (ONFI) has developed a standardized low-level interface for NAND flash chips. This allows interoperability between conforming NAND devices from different vendors. The ONFI specification version 1.0[99] was released on 28 December 2006. It specifies:

- A standard physical interface (pinout) for NAND flash in TSOP-48, WSOP-48, LGA-52, and BGA-63 packages

- A standard command set for reading, writing, and erasing NAND flash chips

- A mechanism for self-identification (comparable to the serial presence detection feature of SDRAM memory modules)

The ONFI group is supported by major NAND flash manufacturers, including Hynix, Intel, Micron Technology, and Numonyx, as well as by major manufacturers of devices incorporating NAND flash chips.[100]

Two major flash device manufacturers, Toshiba and Samsung, have chosen to use an interface of their own design known as Toggle Mode (and now Toggle V2.0). This interface isn't pin-to-pin compatible with the ONFI specification. The result is a product designed for one vendor's devices may not be able to use another vendor's devices.[101]

A group of vendors, including Intel, Dell, and Microsoft, formed a Non-Volatile Memory Host Controller Interface (NVMHCI) Working Group.[102] The goal of the group is to provide standard software and hardware programming interfaces for nonvolatile memory subsystems, including the "flash cache" device connected to the PCI Express bus.

Distinction between NOR and NAND flash

NOR and NAND flash differ in two important ways:

- The connections of the individual memory cells are different.

- The interface provided for reading and writing the memory is different; NOR allows random access, while NAND allows only page access.[103]

NOR and NAND flash get their names from the structure of the interconnections between memory cells. In NOR flash, cells are connected in parallel to the bit lines, allowing cells to be read and programmed individually. The parallel connection of cells resembles the parallel connection of transistors in a CMOS NOR gate. In NAND flash, cells are connected in series, resembling a CMOS NAND gate. The series connections consume less space than parallel ones, reducing the cost of NAND flash. It does not, by itself, prevent NAND cells from being read and programmed individually.

Each NOR flash cell is larger than a NAND flash cell – 10 F2 vs 4 F2 – even when using exactly the same semiconductor device fabrication and so each transistor, contact, etc. is exactly the same size – because NOR flash cells require a separate metal contact for each cell.[104]

Because of the series connection and removal of wordline contacts, a large grid of NAND flash memory cells will occupy perhaps only 60% of the area of equivalent NOR cells[105] (assuming the same CMOS process resolution, for example, 130 nm, 90 nm, or 65 nm). NAND flash's designers realized that the area of a NAND chip, and thus the cost, could be further reduced by removing the external address and data bus circuitry. Instead, external devices could communicate with NAND flash via sequential-accessed command and data registers, which would internally retrieve and output the necessary data. This design choice made random-access of NAND flash memory impossible, but the goal of NAND flash was to replace mechanical hard disks, not to replace ROMs.

| Attribute | NAND | NOR |

|---|---|---|

| Main application | File storage | Code execution |

| Storage capacity | High | Low |

| Cost per bit | Low | |

| Active power | Low | |

| Standby power | Low | |

| Write speed | Fast | |

| Read speed | Fast | |

| Execute in place (XIP) | No | Yes |

| Reliability | High |

Write endurance

The write endurance of SLC floating-gate NOR flash is typically equal to or greater than that of NAND flash, while MLC NOR and NAND flash have similar endurance capabilities. Examples of endurance cycle ratings listed in datasheets for NAND and NOR flash, as well as in storage devices using flash memory, are provided.[106]

| Type of flash memory | Endurance rating (erases per block) | Example(s) of flash memory or storage device |

|---|---|---|

| SLC NAND | 100,000 | Samsung OneNAND KFW4G16Q2M, Toshiba SLC NAND Flash chips,[107][108][109][110][111] Transcend SD500, Fujitsu S26361-F3298 |

| MLC NAND | 5,000 to 10,000 for medium-capacity applications; 1,000 to 3,000 for high-capacity applications[112] | Samsung K9G8G08U0M (Example for medium-capacity applications), Memblaze PBlaze4,[113] ADATA SU900, Mushkin Reactor |

| TLC NAND | 1,000 | Samsung SSD 840 |

| QLC NAND | ? | SanDisk X4 NAND flash SD cards[114][115][116][117] |

| 3D SLC NAND | 100,000 | Samsung Z-NAND[118] |

| 3D MLC NAND | 6,000 to 40,000 | Samsung SSD 850 PRO, Samsung SSD 845DC PRO,[119][120] Samsung 860 PRO |

| 3D TLC NAND | 1,000 to 3,000 | Samsung SSD 850 EVO, Samsung SSD 845DC EVO, Crucial MX300[121][122][123],Memblaze PBlaze5 900, Memblaze PBlaze5 700, Memblaze PBlaze5 910/916,Memblaze PBlaze5 510/516,[124][125][126][127] ADATA SX 8200 PRO (also being sold under "XPG Gammix" branding, model S11 PRO) |

| 3D QLC NAND | 100 to 1,000 | Samsung SSD 860 QVO SATA, Intel SSD 660p, Samsung SSD 980 QVO NVMe, Micron 5210 ION, Samsung SSD BM991 NVMe[128][129][130][131][132][133][134][135] |

| 3D PLC NAND | Unknown | In development by SK Hynix (formerly Intel)[136] and Kioxia (formerly Toshiba Memory).[112] |

| SLC (floating-gate) NOR | 100,000 to 1,000,000 | Numonyx M58BW (Endurance rating of 100,000 erases per block); Spansion S29CD016J (Endurance rating of 1,000,000 erases per block) |

| MLC (floating-gate) NOR | 100,000 | Numonyx J3 flash |

However, by applying certain algorithms and design paradigms such as wear leveling and memory over-provisioning, the endurance of a storage system can be tuned to serve specific requirements.[3][137]

In order to compute the longevity of the NAND flash, one must account for the size of the memory chip, the type of memory (e.g. SLC/MLC/TLC), and use pattern.

3D NAND performance may degrade as layers are added.[118]

Flash file systems

Because of the particular characteristics of flash memory, it is best used with either a controller to perform wear leveling and error correction or specifically designed flash file systems, which spread writes over the media and deal with the long erase times of NOR flash blocks.[138] The basic concept behind flash file systems is the following: when the flash store is to be updated, the file system will write a new copy of the changed data to a fresh block, remap the file pointers, then erase the old block later when it has time.

In practice, flash file systems are used only for memory technology devices (MTDs), which are embedded flash memories that do not have a controller. Removable flash memory cards, SSDs, eMMC/eUFS chips and USB flash drives have built-in controllers to perform wear leveling and error correction so use of a specific flash file system does not add any benefit.

Capacity

Multiple chips are often arrayed or die stacked to achieve higher capacities[139] for use in consumer electronic devices such as multimedia players or GPSs. The capacity scaling (increase) of flash chips used to follow Moore's Law because they are manufactured with many of the same integrated circuits techniques and equipment. Since the introduction of 3D NAND, scaling is no longer necessarily associated with Moore's law since ever smaller transistors (cells) are no longer used.

Consumer flash storage devices typically are advertised with usable sizes expressed as a small integer power of two (2, 4, 8, etc.) and a designation of megabytes (MB) or gigabytes (GB); e.g., 512 MB, 8 GB. This includes SSDs marketed as hard drive replacements, in accordance with traditional hard drives, which use decimal prefixes.[140] Thus, an SSD marked as "64 GB" is at least 64 × 10003 bytes (64 GB). Most users will have slightly less capacity than this available for their files, due to the space taken by file system metadata.

The flash memory chips inside them are sized in strict binary multiples, but the actual total capacity of the chips is not usable at the drive interface. It is considerably larger than the advertised capacity in order to allow for distribution of writes (wear leveling), for sparing, for error correction codes, and for other metadata needed by the device's internal firmware.

In 2005, Toshiba and SanDisk developed a NAND flash chip capable of storing 1 GB of data using multi-level cell (MLC) technology, capable of storing two bits of data per cell. In September 2005, Samsung Electronics announced that it had developed the world's first 2 GB chip.[141]

In March 2006, Samsung announced flash hard drives with a capacity of 4 GB, essentially the same order of magnitude as smaller laptop hard drives, and in September 2006, Samsung announced an 8 GB chip produced using a 40 nm manufacturing process.[142] In January 2008, SanDisk announced availability of their 16 GB MicroSDHC and 32 GB SDHC Plus cards.[143][144]

More recent flash drives (as of 2012) have much greater capacities, holding 64, 128, and 256 GB.[145]

A joint development at Intel and Micron will allow the production of 32-layer 3.5 terabyte (TB) NAND flash sticks and 10 TB standard-sized SSDs. The device includes 5 packages of 16 × 48 GB TLC dies, using a floating gate cell design.[146]

Flash chips continue to be manufactured with capacities under or around 1 MB (e.g. for BIOS-ROMs and embedded applications).

In July 2016, Samsung announced the 4 TB Samsung 850 EVO which utilizes their 256 Gbit 48-layer TLC 3D V-NAND.[147] In August 2016, Samsung announced a 32 TB 2.5-inch SAS SSD based on their 512 Gbit 64-layer TLC 3D V-NAND. Further, Samsung expects to unveil SSDs with up to 100 TB of storage by 2020.[148]

Transfer rates

Flash memory devices are typically much faster at reading than writing.[149] Performance also depends on the quality of storage controllers which become more critical when devices are partially full.[149] Even when the only change to manufacturing is die-shrink, the absence of an appropriate controller can result in degraded speeds.[150]

Applications

Serial flash

Serial flash is a small, low-power flash memory that provides only serial access to the data - rather than addressing individual bytes, the user reads or writes large contiguous groups of bytes in the address space serially. Serial Peripheral Interface Bus (SPI) is a typical protocol for accessing the device. When incorporated into an embedded system, serial flash requires fewer wires on the PCB than parallel flash memories, since it transmits and receives data one bit at a time. This may permit a reduction in board space, power consumption, and total system cost.

There are several reasons why a serial device, with fewer external pins than a parallel device, can significantly reduce overall cost:

- Many ASICs are pad-limited, meaning that the size of the die is constrained by the number of wire bond pads, rather than the complexity and number of gates used for the device logic. Eliminating bond pads thus permits a more compact integrated circuit, on a smaller die; this increases the number of dies that may be fabricated on a wafer, and thus reduces the cost per die.

- Reducing the number of external pins also reduces assembly and packaging costs. A serial device may be packaged in a smaller and simpler package than a parallel device.

- Smaller and lower pin-count packages occupy less PCB area.

- Lower pin-count devices simplify PCB routing.

There are two major SPI flash types. The first type is characterized by small pages and one or more internal SRAM page buffers allowing a complete page to be read to the buffer, partially modified, and then written back (for example, the Atmel AT45 DataFlash or the Micron Technology Page Erase NOR Flash). The second type has larger sectors where the smallest sectors typically found in this type of SPI flash are 4 kB, but they can be as large as 64 kB. Since this type of SPI flash lacks an internal SRAM buffer, the complete page must be read out and modified before being written back, making it slow to manage. However, the second type is cheaper than the first and is therefore a good choice when the application is code shadowing.

The two types are not easily exchangeable, since they do not have the same pinout, and the command sets are incompatible.

Most FPGAs are based on SRAM configuration cells and require an external configuration device, often a serial flash chip, to reload the configuration bitstream every power cycle.[151]

Firmware storage

With the increasing speed of modern CPUs, parallel flash devices are often much slower than the memory bus of the computer they are connected to. Conversely, modern SRAM offers access times below 10 ns, while DDR2 SDRAM offers access times below 20 ns. Because of this, it is often desirable to shadow code stored in flash into RAM; that is, the code is copied from flash into RAM before execution, so that the CPU may access it at full speed. Device firmware may be stored in a serial flash device, and then copied into SDRAM or SRAM when the device is powered-up.[152] Using an external serial flash device rather than on-chip flash removes the need for significant process compromise (a manufacturing process that is good for high-speed logic is generally not good for flash and vice versa). Once it is decided to read the firmware in as one big block it is common to add compression to allow a smaller flash chip to be used. Typical applications for serial flash include storing firmware for hard drives, Ethernet controllers, DSL modems, wireless network devices, etc.

Flash memory as a replacement for hard drives

One more recent application for flash memory is as a replacement for hard disks. Flash memory does not have the mechanical limitations and latencies of hard drives, so a solid-state drive (SSD) is attractive when considering speed, noise, power consumption, and reliability. Flash drives are gaining traction as mobile device secondary storage devices; they are also used as substitutes for hard drives in high-performance desktop computers and some servers with RAID and SAN architectures.

There remain some aspects of flash-based SSDs that make them unattractive. The cost per gigabyte of flash memory remains significantly higher than that of hard disks.[153] Also flash memory has a finite number of P/E cycles, but this seems to be currently under control since warranties on flash-based SSDs are approaching those of current hard drives.[154] In addition, deleted files on SSDs can remain for an indefinite period of time before being overwritten by fresh data; erasure or shred techniques or software that work well on magnetic hard disk drives have no effect on SSDs, compromising security and forensic examination. However, due to the so-called TRIM command employed by most solid state drives, which marks the logical block addresses occupied by the deleted file as unused to enable garbage collection, data recovery software is not able to restore files deleted from such.

For relational databases or other systems that require ACID transactions, even a modest amount of flash storage can offer vast speedups over arrays of disk drives.[155][156]

In May 2006, Samsung Electronics announced two flash-memory based PCs, the Q1-SSD and Q30-SSD were expected to become available in June 2006, both of which used 32 GB SSDs, and were at least initially available only in South Korea.[157] The Q1-SSD and Q30-SSD launch was delayed and finally was shipped in late August 2006.[158]

The first flash-memory based PC to become available was the Sony Vaio UX90, announced for pre-order on 27 June 2006 and began to be shipped in Japan on 3 July 2006 with a 16Gb flash memory hard drive.[159] In late September 2006 Sony upgraded the flash-memory in the Vaio UX90 to 32Gb.[160]

A solid-state drive was offered as an option with the first MacBook Air introduced in 2008, and from 2010 onwards, all models were shipped with an SSD. Starting in late 2011, as part of Intel's Ultrabook initiative, an increasing number of ultra-thin laptops are being shipped with SSDs standard.

There are also hybrid techniques such as hybrid drive and ReadyBoost that attempt to combine the advantages of both technologies, using flash as a high-speed non-volatile cache for files on the disk that are often referenced, but rarely modified, such as application and operating system executable files.

Flash memory as RAM

As of 2012, there are attempts to use flash memory as the main computer memory, DRAM.[161]

Archival or long-term storage

It is unclear how long flash memory will persist under archival conditions (i.e. benign temperature and humidity with infrequent access with or without prophylactic rewrite). Datasheets of Atmel's flash-based "ATmega" microcontrollers typically promise retention times of 20 years at 85 °C (185 °F) and 100 years at 25 °C (77 °F).[162] The retention span varies among types and models of flash storage. When supplied with power and idle, the charge of the transistors holding the data is routinely refreshed by the Firmware of the flash storage.[163]

An article from CMU in 2015 writes that "Today's flash devices, which do not require flash refresh, have a typical retention age of 1 year at room temperature." And that temperature can lower the retention time exponentially. The phenomenon can be modeled by the Arrhenius equation.[164][165]

Industry

One source states that, in 2008, the flash memory industry includes about US$9.1 billion in production and sales. Other sources put the flash memory market at a size of more than US$20 billion in 2006, accounting for more than eight percent of the overall semiconductor market and more than 34 percent of the total semiconductor memory market.[166] In 2012, the market was estimated at $26.8 billion.[167] It can take up to 10 weeks to produce a flash memory chip.[168]

Manufacturers

The following are the largest NAND flash memory manufacturers, as of the first quarter of 2019.[169]

- Samsung Electronics – 34.9%

- Kioxia – 18.1%

- Western Digital Corporation – 14%

- Micron Technology – 13.5%

- SK Hynix – 10.3%

- Intel – 8.7%

Shipments

| Year(s) | Discrete flash memory chips | Flash memory data capacity (gigabytes) | Floating-gate MOSFET memory cells (billions) |

|---|---|---|---|

| 1992 | 26,000,000[170] | 3[170] | 24[lower-alpha 1] |

| 1993 | 73,000,000[170] | 17[170] | 139[lower-alpha 1] |

| 1994 | 112,000,000[170] | 25[170] | 203[lower-alpha 1] |

| 1995 | 235,000,000[170] | 38[170] | 300[lower-alpha 1] |

| 1996 | 359,000,000[170] | 140[170] | 1,121[lower-alpha 1] |

| 1997 | 477,200,000+[171] | 317+[171] | 2,533+[lower-alpha 1] |

| 1998 | 762,195,122[172] | 455+[171] | 3,642+[lower-alpha 1] |

| 1999 | 12,800,000,000[173] | 635+[171] | 5,082+[lower-alpha 1] |

| 2000–2004 | 134,217,728,000 (NAND)[174] | 1,073,741,824,000 (NAND)[174] | |

| 2005–2007 | ? | ||

| 2008 | 1,226,215,645 (mobile NAND)[175] | ||

| 2009 | 1,226,215,645+ (mobile NAND) | ||

| 2010 | 7,280,000,000+[lower-alpha 2] | ||

| 2011 | 8,700,000,000[177] | ||

| 2012 | 5,151,515,152 (serial)[178] | ||

| 2013 | ? | ||

| 2014 | ? | 59,000,000,000[179] | 118,000,000,000+[lower-alpha 1] |

| 2015 | 7,692,307,692 (NAND)[180] | 85,000,000,000[181] | 170,000,000,000+[lower-alpha 1] |

| 2016 | ? | 100,000,000,000[182] | 200,000,000,000+[lower-alpha 1] |

| 2017 | ? | 148,200,000,000[lower-alpha 3] | 296,400,000,000+[lower-alpha 1] |

| 2018 | ? | 231,640,000,000[lower-alpha 4] | 463,280,000,000+[lower-alpha 1] |

| 1992–2018 | 45,358,454,134+ memory chips | 758,057,729,630+ gigabytes | 2,321,421,837,044 billion+ cells |

In addition to individual flash memory chips, flash memory is also embedded in microcontroller (MCU) chips and system-on-chip (SoC) devices.[186] Flash memory is embedded in ARM chips,[186] which have sold 150 billion units worldwide as of 2019,[187] and in programmable system-on-chip (PSoC) devices, which have sold 1.1 billion units as of 2012.[188] This adds up to at least 151.1 billion MCU and SoC chips with embedded flash memory, in addition to the 45.4 billion known individual flash chip sales as of 2015, totalling at least 196.5 billion chips containing flash memory.

Flash scalability

Due to its relatively simple structure and high demand for higher capacity, NAND flash memory is the most aggressively scaled technology among electronic devices. The heavy competition among the top few manufacturers only adds to the aggressiveness in shrinking the floating-gate MOSFET design rule or process technology node.[86] While the expected shrink timeline is a factor of two every three years per original version of Moore's law, this has recently been accelerated in the case of NAND flash to a factor of two every two years.

| ITRS or company | 2010 | 2011 | 2012 | 2013 | 2014 | 2015 | 2016 | 2017 | 2018 |

|---|---|---|---|---|---|---|---|---|---|

| ITRS Flash Roadmap 2011[189] | 32 nm | 22 nm | 20 nm | 18 nm | 16 nm | ||||

| Updated ITRS Flash Roadmap[190] | 17 nm | 15 nm | 14 nm | ||||||

| Samsung[189][190][191] (Samsung 3D NAND)[190] | 35–20 nm[30] | 27 nm | 21 nm (MLC, TLC) | 19–16 nm 19–10 nm (MLC, TLC)[192] | 19–10 nm V-NAND (24L) | 16–10 nm V-NAND (32L) | 16–10 nm | 12–10 nm | 12–10 nm |

| Micron, Intel[189][190][191] | 34–25 nm | 25 nm | 20 nm (MLC + HKMG) | 20 nm (TLC) | 16 nm | 16 nm 3D NAND | 16 nm 3D NAND | 12 nm 3D NAND | 12 nm 3D NAND |

| Toshiba, WD (SanDisk)[189][190][191] | 43–32 nm 24 nm (Toshiba)[193] | 24 nm | 19 nm (MLC, TLC) | 15 nm | 15 nm 3D NAND | 15 nm 3D NAND | 12 nm 3D NAND | 12 nm 3D NAND | |

| SK Hynix[189][190][191] | 46–35 nm | 26 nm | 20 nm (MLC) | 16 nm | 16 nm | 16 nm | 12 nm | 12 nm |

As the MOSFET feature size of flash memory cells reaches the 15-16 nm minimum limit, further flash density increases will be driven by TLC (3 bits/cell) combined with vertical stacking of NAND memory planes. The decrease in endurance and increase in uncorrectable bit error rates that accompany feature size shrinking can be compensated by improved error correction mechanisms.[194] Even with these advances, it may be impossible to economically scale flash to smaller and smaller dimensions as the number of electron holding capacity reduces. Many promising new technologies (such as FeRAM, MRAM, PMC, PCM, ReRAM, and others) are under investigation and development as possible more scalable replacements for flash.[195]

Timeline

| Date of introduction | Chip name | Memory Package Capacity (in bits; Megabits (Mb), Gigabits (Gb), Terabits (Tb) | Flash type | Cell type | Manufacturer(s) | Process | Area | Ref |

|---|---|---|---|---|---|---|---|---|

| 1984 | ? | ? | NOR | SLC | Toshiba | ? | ? | [19] |

| 1985 | ? | 256 kb | NOR | SLC | Toshiba | 2,000 nm | ? | [27] |

| 1987 | ? | ? | NAND | SLC | Toshiba | ? | ? | [1] |

| 1989 | ? | 1 Mb | NOR | SLC | Seeq, Intel | ? | ? | [27] |

| 4 Mb | NAND | SLC | Toshiba | 1,000 nm | ||||

| 1991 | ? | 16 Mb | NOR | SLC | Mitsubishi | 600 nm | ? | [27] |

| 1993 | DD28F032SA | 32 Mb | NOR | SLC | Intel | ? | 280 mm² | [196][197] |

| 1994 | ? | 64 Mb | NOR | SLC | NEC | 400 nm | ? | [27] |

| 1995 | ? | 16 Mb | DINOR | SLC | Mitsubishi, Hitachi | ? | ? | [27][198] |

| NAND | SLC | Toshiba | ? | ? | [199] | |||

| 32 Mb | NAND | SLC | Hitachi, Samsung, Toshiba | ? | ? | [27] | ||

| 34 Mb | Serial | SLC | SanDisk | |||||

| 1996 | ? | 64 Mb | NAND | SLC | Hitachi, Mitsubishi | 400 nm | ? | [27] |

| QLC | NEC | |||||||

| 128 Mb | NAND | SLC | Samsung, Hitachi | ? | ||||

| 1997 | ? | 32 Mb | NOR | SLC | Intel, Sharp | 400 nm | ? | [200] |

| NAND | SLC | AMD, Fujitsu | 350 nm | |||||

| 1999 | ? | 256 Mb | NAND | SLC | Toshiba | 250 nm | ? | [27] |

| MLC | Hitachi | |||||||

| 2000 | ? | 32 Mb | NOR | SLC | Toshiba | 250 nm | ? | [27] |

| 64 Mb | NOR | QLC | STMicroelectronics | 180 nm | ||||

| 512 Mb | NAND | SLC | Toshiba | ? | ? | [201] | ||

| 2001 | ? | 512 Mb | NAND | MLC | Hitachi | ? | ? | [27] |

| 1 Gibit | NAND | MLC | Samsung | |||||

| Toshiba, SanDisk | 160 nm | ? | [202] | |||||

| 2002 | ? | 512 Mb | NROM | MLC | Saifun | 170 nm | ? | [27] |

| 2 Gb | NAND | SLC | Samsung, Toshiba | ? | ? | [203][204] | ||

| 2003 | ? | 128 Mb | NOR | MLC | Intel | 130 nm | ? | [27] |

| 1 Gb | NAND | MLC | Hitachi | |||||

| 2004 | ? | 8 Gb | NAND | SLC | Samsung | 60 nm | ? | [203] |

| 2005 | ? | 16 Gb | NAND | SLC | Samsung | 50 nm | ? | [30] |

| 2006 | ? | 32 Gb | NAND | SLC | Samsung | 40 nm | ||

| April 2007 | THGAM | 128 Gb | Stacked NAND | SLC | Toshiba | 56 nm | 252 mm² | [46] |

| September 2007 | ? | 128 Gb | Stacked NAND | SLC | Hynix | ? | ? | [47] |

| 2008 | THGBM | 256 Gb | Stacked NAND | SLC | Toshiba | 43 nm | 353 mm² | [48] |

| 2009 | ? | 32 Gb | NAND | TLC | Toshiba | 32 nm | 113 mm² | [28] |

| 64 Gb | NAND | QLC | Toshiba, SanDisk | 43 nm | ? | [28][29] | ||

| 2010 | ? | 64 Gb | NAND | SLC | Hynix | 20 nm | ? | [205] |

| TLC | Samsung | 20 nm | ? | [30] | ||||

| THGBM2 | 1 Tb | Stacked NAND | QLC | Toshiba | 32 nm | 374 mm² | [49] | |

| 2011 | KLMCG8GE4A | 512 Gb | Stacked NAND | MLC | Samsung | ? | 192 mm² | [206] |

| 2013 | ? | ? | NAND | SLC | SK Hynix | 16 nm | ? | [205] |

| 128 Gb | V-NAND | TLC | Samsung | 10 nm | ? | [192] | ||

| 2015 | ? | 256 Gb | V-NAND | TLC | Samsung | ? | ? | [30] |

| 2017 | ? | 512 Gb | V-NAND | TLC | Samsung | ? | ? | [52] |

| 768 Gb | V-NAND | QLC | Toshiba | ? | ? | [207] | ||

| KLUFG8R1EM | 4 Tb | Stacked V-NAND | TLC | Samsung | ? | 150 mm² | [52] | |

| 2018 | ? | 1 Tb | V-NAND | QLC | Samsung | ? | ? | [208] |

| 1.33 Tb | V-NAND | QLC | Toshiba | ? | 158 mm² | [209][210] | ||

| 2019 | ? | 512 Gb | V-NAND | QLC | Samsung | ? | ? | [53][54] |

| 1 Tb | V-NAND | TLC | SK Hynix | ? | ? | [211] | ||

| eUFS (1 TB) | 8 Tb | 16 layer Stacked V-NAND[212] | QLC | Samsung | ? | 150 mm² | [53][54][213] |

See also

- eMMC

- Flash memory controller

- List of flash file systems

- microSDXC (up to 2 TB), and the successor format Secure Digital Ultra Capacity (SDUC) supporting cards up to 128 TiB

- Open NAND Flash Interface Working Group

- Read-mostly memory (RMM)

- Universal Flash Storage

- USB flash drive security

- Write amplification

Notes

- Single-level cell (1-bit per cell) up until 2009. Multi-level cell (up to 4-bit or half-byte per cell) commercialised in 2009.[28][29]

- Flash memory chip shipments in 2010:

- NOR – 3.64 billion[176]

- NAND – 3.64 billion+ (est.)

- Flash memory data capacity shipments in 2017:

- NAND non-volatile memory (NVM) – 85 exabytes (est.)[183]

- Solid-state drive (SSD) – 63.2 exabytes[184]

- Flash memory data capacity shipments in 2018 (est.)

References

- "1987: Toshiba Launches NAND Flash". eWeek. 11 April 2012. Retrieved 20 June 2019.

- "A Flash Storage Technical and Economic Primer". FlashStorage.com. 30 March 2015. Archived from the original on 20 July 2015.

- Mittal, Sparsh; Vetter, Jeffrey S. (2016). "A Survey of Software Techniques for Using Non-Volatile Memories for Storage and Main Memory Systems". IEEE Transactions on Parallel and Distributed Systems. 27 (5): 1537–1550. doi:10.1109/TPDS.2015.2442980. S2CID 206771165.

- https://www.micron.com/-/media/client/global/documents/products/technical-note/dram-modules/tn_04_42.pdf?rev=e5a1537ce3214de5b695f17c340fd023

- https://whatis.techtarget.com/definition/serial-presence-detect-SPD#:~:text=When%20a%20computer%20is%20booted,%2C%20data%20width%2C%20speed%2C%20and

- Shilov, Anton. "Samsung Starts Production of 1 TB eUFS 2.1 Storage for Smartphones". AnandTech.com.

- Shilov, Anton. "Samsung Starts Production of 512 GB UFS NAND Flash Memory: 64-Layer V-NAND, 860 MB/s Reads". AnandTech.com.

- Kim, Chulbum; Cho, Ji-Ho; Jeong, Woopyo; Park, Il-han; Park, Hyun-Wook; Kim, Doo-Hyun; Kang, Daewoon; Lee, Sunghoon; Lee, Ji-Sang; Kim, Wontae; Park, Jiyoon; Ahn, Yang-lo; Lee, Jiyoung; Lee, Jong-Hoon; Kim, Seungbum; Yoon, Hyun-Jun; Yu, Jaedoeg; Choi, Nayoung; Kwon, Yelim; Kim, Nahyun; Jang, Hwajun; Park, Jonghoon; Song, Seunghwan; Park, Yongha; Bang, Jinbae; Hong, Sangki; Jeong, Byunghoon; Kim, Hyun-Jin; Lee, Chunan; et al. (2017). "11.4 a 512Gb 3b/Cell 64-stacked WL 3D V-NAND flash memory". 2017 IEEE International Solid-State Circuits Conference (ISSCC). pp. 202–203. doi:10.1109/ISSCC.2017.7870331. ISBN 978-1-5090-3758-2. S2CID 206998691.

- "Samsung enables 1TB eUFS 2.1 smartphones - Storage - News - HEXUS.net". m.hexus.net.

- "Not just a flash in the pan". The Economist. 11 March 2006. Retrieved 10 September 2019.

- Bez, R.; Pirovano, A. (2019). Advances in Non-Volatile Memory and Storage Technology. Woodhead Publishing. ISBN 9780081025857.

- "1960 - Metal Oxide Semiconductor (MOS) Transistor Demonstrated". The Silicon Engine. Computer History Museum.

- "1971: Reusable semiconductor ROM introduced". Computer History Museum. Retrieved 19 June 2019.

- Fulford, Adel (24 June 2002). "Unsung hero". Forbes. Archived from the original on 3 March 2008. Retrieved 18 March 2008.

- "How ROM Works". HowStuffWorks. 29 August 2000. Retrieved 10 September 2019.

- US 4531203 Fujio Masuoka

- Semiconductor memory device and method for manufacturing the same

- "NAND Flash Memory: 25 Years of Invention, Development - Data Storage - News & Reviews - eWeek.com". eweek.com.

- "Toshiba: Inventor of Flash Memory". Toshiba. Retrieved 20 June 2019.

- Masuoka, F.; Asano, M.; Iwahashi, H.; Komuro, T.; Tanaka, S. (December 1984). "A new flash E2PROM cell using triple polysilicon technology". 1984 International Electron Devices Meeting: 464–467. doi:10.1109/IEDM.1984.190752. S2CID 25967023.

- Masuoka, F.; Momodomi, M.; Iwata, Y.; Shirota, R. (1987). "New ultra high density EPROM and flash EEPROM with NAND structure cell". Electron Devices Meeting, 1987 International. IEDM 1987. IEEE. doi:10.1109/IEDM.1987.191485.

- Tal, Arie (February 2002). "NAND vs. NOR flash technology: The designer should weigh the options when using flash memory". Archived from the original on 28 July 2010. Retrieved 31 July 2010.

- "H8S/2357 Group, H8S/2357F-ZTATTM, H8S/2398F-ZTATTM Hardware Manual, Section 19.6.1" (PDF). Renesas. October 2004. Retrieved 23 January 2012.

The flash memory can be reprogrammed up to 100 times.

- "AMD DL160 and DL320 Series Flash: New Densities, New Features" (PDF). AMD. July 2003. Archived (PDF) from the original on 24 September 2015. Retrieved 13 November 2014.

The devices offer single-power-supply operation (2.7 V to 3.6 V), sector architecture, Embedded Algorithms, high performance, and a 1,000,000 program/erase cycle endurance guarantee.

- James, Dick (2014). "3D ICs in the real world". 25th Annual SEMI Advanced Semiconductor Manufacturing Conference (ASMC 2014): 113–119. doi:10.1109/ASMC.2014.6846988. ISBN 978-1-4799-3944-2. S2CID 42565898.

- "NEC: News Release 97/10/28-01". www.nec.co.jp.

- "Memory". STOL (Semiconductor Technology Online). Retrieved 25 June 2019.

- "Toshiba Makes Major Advances in NAND Flash Memory with 3-bit-per-cell 32nm generation and with 4-bit-per-cell 43nm technology". Toshiba. 11 February 2009. Retrieved 21 June 2019.

- "SanDisk ships world's first memory cards with 64 gigabit X4 NAND flash". SlashGear. 13 October 2009. Retrieved 20 June 2019.

- "History". Samsung Electronics. Samsung. Retrieved 19 June 2019.

- https://www.electronicdesign.com/technologies/memory/article/21796009/interview-spansions-cto-talks-about-embedded-charge-trap-nor-flash-technology

- Ito, T., & Taito, Y. (2017). SONOS Split-Gate eFlash Memory. Embedded Flash Memory for Embedded Systems: Technology, Design for Sub-Systems, and Innovations, 209–244. doi:10.1007/978-3-319-55306-1_7

- Bez, R., Camerlenghi, E., Modelli, A., & Visconti, A. (2003). Introduction to flash memory. Proceedings of the IEEE, 91(4), 489–502. doi:10.1109/jproc.2003.811702

- Lee, J.-S. (2011). Review paper: Nano-floating gate memory devices. Electronic Materials Letters, 7(3), 175–183. doi:10.1007/s13391-011-0901-5

- https://www.embedded.com/flash-101-types-of-nand-flash/

- Meena, J., Sze, S., Chand, U., & Tseng, T.-Y. (2014). Overview of emerging nonvolatile memory technologies. Nanoscale Research Letters, 9(1), 526. doi:10.1186/1556-276x-9-526

- https://searchstorage.techtarget.com/tip/Charge-trap-technology-advantages-for-3D-NAND-flash-drives

- Grossi, A., Zambelli, C., & Olivo, P. (2016). Reliability of 3D NAND Flash Memories. 3D Flash Memories, 29–62. doi:10.1007/978-94-017-7512-0_2

- Kodama, N.; Oyama, K.; Shirai, H.; Saitoh, K.; Okazawa, T.; Hokari, Y. (December 1991). "A symmetrical side wall (SSW)-DSA cell for a 64 Mbit flash memory". International Electron Devices Meeting 1991 [Technical Digest]: 303–306. doi:10.1109/IEDM.1991.235443. ISBN 0-7803-0243-5. S2CID 111203629.

- Eitan, Boaz. "US Patent 5,768,192: Non-volatile semiconductor memory cell utilizing asymmetrical charge trapping". US Patent & Trademark Office. Retrieved 22 May 2012.

- Fastow, Richard M.; Ahmed, Khaled Z.; Haddad, Sameer; et al. (April 2000). "Bake induced charge gain in NOR flash cells". IEEE Electron Device Letters. 21 (4): 184–186. Bibcode:2000IEDL...21..184F. doi:10.1109/55.830976. S2CID 24724751.

- "Samsung produces first 3D NAND, aims to boost densities, drive lower cost per GB". ExtremeTech. 6 August 2013. Retrieved 4 July 2019.

- "Toshiba announces new "3D" NAND flash technology". Engadget. 12 June 2007. Retrieved 10 July 2019.

- "Samsung Introduces World's First 3D V-NAND Based SSD for Enterprise Applications | Samsung | Samsung Semiconductor Global Website". Samsung.com.

- Clarke, Peter. "Samsung Confirms 24 Layers in 3D NAND". EETimes.

- "TOSHIBA COMMERCIALIZES INDUSTRY'S HIGHEST CAPACITY EMBEDDED NAND FLASH MEMORY FOR MOBILE CONSUMER PRODUCTS". Toshiba. 17 April 2007. Archived from the original on 23 November 2010. Retrieved 23 November 2010.

- "Hynix Surprises NAND Chip Industry". The Korea Times. 5 September 2007. Retrieved 8 July 2019.

- "Toshiba Launches the Largest Density Embedded NAND Flash Memory Devices". Toshiba. 7 August 2008. Retrieved 21 June 2019.

- "Toshiba Launches Industry's Largest Embedded NAND Flash Memory Modules". Toshiba. 17 June 2010. Retrieved 21 June 2019.

- SanDisk. "Western Digital Breaks Boundaries with World's Highest-Capacity microSD Card". SanDisk.com. Archived from the original on 1 September 2017. Retrieved 2 September 2017.

- Bradley, Tony. "Expand Your Mobile Storage With New 400GB microSD Card From SanDisk". Forbes. Archived from the original on 1 September 2017. Retrieved 2 September 2017.

- Shilov, Anton (5 December 2017). "Samsung Starts Production of 512 GB UFS NAND Flash Memory: 64-Layer V-NAND, 860 MB/s Reads". AnandTech. Retrieved 23 June 2019.

- Manners, David (30 January 2019). "Samsung makes 1TB flash eUFS module". Electronics Weekly. Retrieved 23 June 2019.

- Tallis, Billy (17 October 2018). "Samsung Shares SSD Roadmap for QLC NAND And 96-layer 3D NAND". AnandTech. Retrieved 27 June 2019.

- Basinger, Matt (18 January 2007), PSoC Designer Device Selection Guide (PDF), AN2209, archived from the original (PDF) on 31 October 2009,

The PSoC ... utilizes a unique Flash process: SONOS

- https://www.iue.tuwien.ac.at/phd/windbacher/node14.html

- http://www.princeton.edu/~chouweb/newproject/research/SEM/FloatMOSMem.html

- https://www.embedded.com/flash-101-types-of-nand-flash/

- https://www.anandtech.com/show/4902/intel-ssd-710-200gb-review/2

- https://www.electronics-notes.com/articles/electronic_components/semiconductor-ic-memory/flash-wear-levelling-reliability-lifetime.php#:~:text=Flash%20memory%20wear%20out%20mechanism&text=The%20wear%2Dout%20mechanism%20for,the%20flash%20memory%20wear%20issue.

- https://www.hyperstone.com/en/Solid-State-bit-density-and-the-Flash-Memory-Controller-1235,12728.html, Solid State bit density, and the Flash Memory Controller, Retrieved 29. May 2018

- Yasufuku, Tadashi; Ishida, Koichi; Miyamoto, Shinji; Nakai, Hiroto; Takamiya, Makoto; Sakurai, Takayasu; Takeuchi, Ken (2009), Proceedings of the 14th ACM/IEEE international symposium on Low power electronics and design - ISLPED '09, pp. 87–92, doi:10.1145/1594233.1594253, ISBN 9781605586847, S2CID 6055676, archived from the original on 5 March 2016 (abstract).

- Micheloni, Rino; Marelli, Alessia; Eshghi, Kam (2012), Inside Solid State Drives (SSDs), Bibcode:2013issd.book.....M, ISBN 9789400751460, archived from the original on 9 February 2017

- Micheloni, Rino; Crippa, Luca (2010), Inside NAND Flash Memories, ISBN 9789048194315, archived from the original on 9 February 2017 In particular, pp 515-536: K. Takeuchi. "Low power 3D-integrated SSD"

- Mozel, Tracey (2009), CMOSET Fall 2009 Circuits and Memories Track Presentation Slides, ISBN 9781927500217, archived from the original on 9 February 2017

- Tadashi Yasufuku et al., "Inductor and TSV Design of 20-V Boost Converter for Low Power 3D Solid State Drive with NAND Flash Memories" Archived 4 February 2016 at the Wayback Machine. 2010.

- Hatanaka, T. and Takeuchi, K. "4-times faster rising VPASS (10V), 15% lower power VPGM (20V), wide output voltage range voltage generator system for 4-times faster 3D-integrated solid-state drives". 2011.

- Takeuchi, K., "Low power 3D-integrated Solid-State Drive (SSD) with adaptive voltage generator". 2010.

- Ishida, K. et al., "1.8 V Low-Transient-Energy Adaptive Program-Voltage Generator Based on Boost Converter for 3D-Integrated NAND Flash SSD". 2011.

- A. H. Johnston, "Space Radiation Effects in Advanced Flash Memories" Archived 4 March 2016 at the Wayback Machine. NASA Electronic Parts and Packaging Program (NEPP). 2001. "... internal transistors used for the charge pump and erase/write control have much thicker oxides because of the requirement for high voltage. This causes flash devices to be considerably more sensitive to total dose damage compared to other ULSI technologies. It also implies that write and erase functions will be the first parameters to fail from total dose. ... Flash memories will work at much higher radiation levels in the read mode. ... The charge pumps that are required to generate the high voltage for erasing and writing are usually the most sensitive circuit functions, usually failing below 10 krad(SI)."

- Zitlaw, Cliff. "The Future of NOR Flash Memory". Memory Designline. UBM Media. Retrieved 3 May 2011.

- https://www.hyperstone.com/en/NAND-Flash-controllers-The-key-to-endurance-and-reliability-1256,12728.html NAND Flash Controllers - The key to endurance and reliability, Retrieved 7. June 2018

- "Samsung moves into mass production of 3D flash memory". Gizmag.com. 27 August 2013. Archived from the original on 27 August 2013. Retrieved 27 August 2013.

- "Samsung Electronics Starts Mass Production of Industry First 3-bit 3D V-NAND Flash Memory". news.samsung.com.

- "Samsung V-NAND technology" (PDF). Samsung Electronics. September 2014. Archived from the original (PDF) on 27 March 2016. Retrieved 27 March 2016.

- https://www.anandtech.com/show/16230/micron-announces-176layer-3d-nand

- "Samsung said to be developing industry's first 160-layer NAND flash memory chip". TechSpot.

- "Toshiba's Cost Model for 3D NAND". www.linkedin.com.

- "AVR105: Power Efficient High Endurance Parameter Storage in Flash Memory". p. 3

- Jonathan Thatcher, Fusion-io; Tom Coughlin, Coughlin Associates; Jim Handy, Objective-Analysis; Neal Ekker, Texas Memory Systems (April 2009). "NAND Flash Solid State Storage for the Enterprise, An In-depth Look at Reliability" (PDF). Solid State Storage Initiative (SSSI) of the Storage Network Industry Association (SNIA). Archived (PDF) from the original on 14 October 2011. Retrieved 6 December 2011. Cite journal requires

|journal=(help)CS1 maint: multiple names: authors list (link) - "Micron Collaborates with Sun Microsystems to Extend Lifespan of Flash-Based Storage, Achieves One Million Write Cycles" (Press release). Micron Technology, Inc. 17 December 2008. Archived from the original on 4 March 2016.

- "Taiwan engineers defeat limits of flash memory". phys.org. Archived from the original on 9 February 2016.

- "Flash memory made immortal by fiery heat". theregister.co.uk. Archived from the original on 13 September 2017.

- "Flash memory breakthrough could lead to even more reliable data storage". news.yahoo.com. Archived from the original on 21 December 2012.

- "TN-29-17 NAND Flash Design and Use Considerations Introduction" (PDF). Micron. April 2010. Archived (PDF) from the original on 12 December 2015. Retrieved 29 July 2011.