Manganese dioxide

Manganese(IV) oxide is the inorganic compound with the formula MnO

2. This blackish or brown solid occurs naturally as the mineral pyrolusite, which is the main ore of manganese and a component of manganese nodules. The principal use for MnO

2 is for dry-cell batteries, such as the alkaline battery and the zinc-carbon battery.[4] MnO

2 is also used as a pigment and as a precursor to other manganese compounds, such as KMnO

4. It is used as a reagent in organic synthesis, for example, for the oxidation of allylic alcohols. MnO

2 is α polymorph that can incorporate a variety of atoms (as well as water molecules) in the "tunnels" or "channels" between the manganese oxide octahedra. There is considerable interest in α-MnO

2 as a possible cathode for lithium ion batteries.[5][6]

_oxide.jpg.webp) | |

| |

| Names | |

|---|---|

| IUPAC names

Manganese oxide Manganese(IV) oxide | |

| Other names

Pyrolusite, hyperoxide of manganese, black oxide of manganese, manganic oxide | |

| Identifiers | |

3D model (JSmol) |

|

| ChEBI | |

| ChemSpider | |

| ECHA InfoCard | 100.013.821 |

| EC Number |

|

PubChem CID |

|

| RTECS number |

|

| UNII | |

CompTox Dashboard (EPA) |

|

| |

| |

| Properties | |

| MnO 2 | |

| Molar mass | 86.9368 g/mol |

| Appearance | Brown-black solid |

| Density | 5.026 g/cm3 |

| Melting point | 535 °C (995 °F; 808 K) (decomposes) |

| insoluble | |

| +2280.0·10−6 cm3/mol[1] | |

| Structure[2] | |

| Tetragonal, tP6, No. 136 | |

| P42/mnm | |

a = 0.44008 nm, b = 0.44008 nm, c = 0.28745 nm | |

Formula units (Z) |

2 |

| Thermochemistry[3] | |

Heat capacity (C) |

54.1 J·mol−1·K−1 |

Std molar entropy (S |

53.1 J·mol−1·K−1 |

Std enthalpy of formation (ΔfH⦵298) |

−520.0 kJ·mol−1 |

Gibbs free energy (ΔfG˚) |

−465.1 kJ·mol−1 |

| Hazards | |

| Safety data sheet | ICSC 0175 |

EU classification (DSD) (outdated) |

Harmful (Xn) Oxidizer (O) |

| R-phrases (outdated) | R20/22 |

| S-phrases (outdated) | (S2), S25 |

| NFPA 704 (fire diamond) | |

| Flash point | 535 °C (995 °F; 808 K) |

| Related compounds | |

Other anions |

Manganese disulfide |

Other cations |

Technetium dioxide Rhenium dioxide |

| Manganese(II) oxide Manganese(II,III) oxide Manganese(III) oxide Manganese heptoxide | |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa). | |

| Infobox references | |

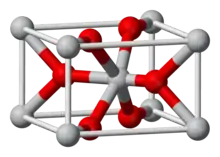

Structure

Several polymorphs of MnO

2 are claimed, as well as a hydrated form. Like many other dioxides, MnO

2 crystallizes in the rutile crystal structure (this polymorph is called pyrolusite or β-MnO

2), with three-coordinate oxide and octahedral metal centres.[4] MnO

2 is characteristically nonstoichiometric, being deficient in oxygen. The complicated solid-state chemistry of this material is relevant to the lore of "freshly prepared" MnO

2 in organic synthesis. The α-polymorph of MnO

2 has a very open structure with "channels" which can accommodate metal atoms such as silver or barium. α-MnO

2 is often called hollandite, after a closely related mineral.

Production

Naturally occurring manganese dioxide contains impurities and a considerable amount of manganese(III) oxide. Only a limited number of deposits contain the γ modification in purity sufficient for the battery industry.

Production of batteries and ferrite (two of the primary uses of manganese dioxide) requires high purity manganese dioxide. Batteries require "electrolytic manganese dioxide" while ferrites require "chemical manganese dioxide".[7]

Chemical manganese dioxide

One method starts with natural manganese dioxide and converts it using dinitrogen tetroxide and water to a manganese(II) nitrate solution. Evaporation of the water leaves the crystalline nitrate salt. At temperatures of 400 °C, the salt decomposes, releasing N

2O

4 and leaving a residue of purified manganese dioxide.[7] These two steps can be summarized as:

- MnO

2 + N

2O

4 ⇌ Mn(NO

3)

2

In another process manganese dioxide is carbothermically reduced to manganese(II) oxide which is dissolved in sulfuric acid. The filtered solution is treated with ammonium carbonate to precipitate MnCO

3. The carbonate is calcined in air to give a mixture of manganese(II) and manganese(IV) oxides. To complete the process, a suspension of this material in sulfuric acid is treated with sodium chlorate. Chloric acid, which forms in situ, converts any Mn(III) and Mn(II) oxides to the dioxide, releasing chlorine as a by-product.[7]

A third process involves manganese heptoxide and manganese monoxide. The two reagents combine with a 1:3 ratio to form manganese dioxide:

- Mn

2O

7 + 3 MnO → 5 MnO

2

Lastly, the action of potassium permanganate over manganese sulfate crystals produces the desired oxide.[8]

- 2 KMnO

4 + 3 MnSO

4 + 2 H

2O→ 5 MnO

2 + K

2SO

4 + 2 H

2SO

4

Electrolytic manganese dioxide

Electrolytic manganese dioxide (EMD) is used in zinc–carbon batteries together with zinc chloride and ammonium chloride. EMD is commonly used in zinc manganese dioxide rechargeable alkaline (Zn RAM) cells also. For these applications, purity is extremely important. EMD is produced in a similar fashion as electrolytic tough pitch (ETP) copper: The manganese dioxide is dissolved in sulfuric acid (sometimes mixed with manganese sulfate) and subjected to a current between two electrodes. The MnO2 dissolves, enters solution as the sulfate, and is deposited on the anode.

Reactions

The important reactions of MnO

2 are associated with its redox, both oxidation and reduction.

Reduction

MnO

2 is the principal precursor to ferromanganese and related alloys, which are widely used in the steel industry. The conversions involve carbothermal reduction using coke:

- MnO

2 + 2 C → Mn + 2 CO

The key reactions of MnO

2 in batteries is the one-electron reduction:

- MnO

2 + e− + H+

→ MnO(OH)

MnO

2 catalyses several reactions that form O

2. In a classical laboratory demonstration, heating a mixture of potassium chlorate and manganese dioxide produces oxygen gas. Manganese dioxide also catalyses the decomposition of hydrogen peroxide to oxygen and water:

- 2 H

2O

2 → 2 H

2O + O

2

Manganese dioxide decomposes above about 530 °C to manganese(III) oxide and oxygen. At temperatures close to 1000 °C, the mixed-valence compound Mn

3O

4 forms. Higher temperatures give MnO.

Hot concentrated sulfuric acid reduces the MnO

2 to manganese(II) sulfate:[4]

- 2 MnO

2 + 2 H

2SO

4 → 2 MnSO

4 + O

2 + 2 H

2O

The reaction of hydrogen chloride with MnO

2 was used by Carl Wilhelm Scheele in the original isolation of chlorine gas in 1774:

- MnO

2 + 4 HCl → MnCl

2 + Cl

2 + 2 H

2O

As a source of hydrogen chloride, Scheele treated sodium chloride with concentrated sulfuric acid.[4]

- E

o(MnO

2(s) + 4 H+

+ 2 e− ⇌ Mn2+ + 2 H

2O) = +1.23 V - E

o(Cl

2(g) + 2 e− ⇌ 2 Cl−) = +1.36 V

- E

The standard electrode potentials for the half reactions indicate that the reaction is endothermic at pH = 0 (1 M [H+

]), but it is favoured by the lower pH as well as the evolution (and removal) of gaseous chlorine.

This reaction is also a convenient way to remove the manganese dioxide precipitate from the ground glass joints after running a reaction (i. e., an oxidation with potassium permanganate).

Oxidation

Heating a mixture of KOH and MnO

2 in air gives green potassium manganate:

- 2 MnO

2 + 4 KOH + O

2 → 2 K

2MnO

4 + 2 H

2O

Potassium manganate is the precursor to potassium permanganate, a common oxidant.

Applications

The predominant application of MnO

2 is as a component of dry cell batteries: alkaline batteries and so called Leclanché cell, or zinc–carbon batteries. Approximately 500,000 tonnes are consumed for this application annually.[9] Other industrial applications include the use of MnO

2 as an inorganic pigment in ceramics and in glassmaking.

Organic synthesis

A specialized use of manganese dioxide is as oxidant in organic synthesis.[10] The effectiveness of the reagent depends on the method of preparation, a problem that is typical for other heterogeneous reagents where surface area, among other variables, is a significant factor.[11] The mineral pyrolusite makes a poor reagent. Usually, however, the reagent is generated in situ by treatment of an aqueous solution KMnO

4 with a Mn(II) salt, typically the sulfate. MnO

2 oxidizes allylic alcohols to the corresponding aldehydes or ketones:[12]

- cis-RCH=CHCH

2OH + MnO

2 → cis-RCH=CHCHO + MnO + H

2O

- cis-RCH=CHCH

The configuration of the double bond is conserved in the reaction. The corresponding acetylenic alcohols are also suitable substrates, although the resulting propargylic aldehydes can be quite reactive. Benzylic and even unactivated alcohols are also good substrates. 1,2-Diols are cleaved by MnO

2 to dialdehydes or diketones. Otherwise, the applications of MnO

2 are numerous, being applicable to many kinds of reactions including amine oxidation, aromatization, oxidative coupling, and thiol oxidation.

See also

References

- Rumble, p. 4.71

- Haines, J.; Léger, J.M.; Hoyau, S. (1995). "Second-order rutile-type to CaCl2-type phase transition in β-MnO2 at high pressure". Journal of Physics and Chemistry of Solids. 56 (7): 965–973. doi:10.1016/0022-3697(95)00037-2.

- Rumble, p. 5.25

- Greenwood, Norman N.; Earnshaw, Alan (1984). Chemistry of the Elements. Oxford: Pergamon Press. pp. 1218–20. ISBN 978-0-08-022057-4..

- Barbato, S (31 May 2001). "Hollandite cathodes for lithium ion batteries. 2. Thermodynamic and kinetics studies of lithium insertion into BaMMn7O16 (M=Mg, Mn, Fe, Ni)". Electrochimica Acta. 46 (18): 2767–2776. doi:10.1016/S0013-4686(01)00506-0. hdl:10533/173039.

- Tompsett, David A.; Islam, M. Saiful (25 June 2013). "Electrochemistry of Hollandite α-MnO : Li-Ion and Na-Ion Insertion and Li Incorporation". Chemistry of Materials. 25 (12): 2515–2526. CiteSeerX 10.1.1.728.3867. doi:10.1021/cm400864n.

- Preisler, Eberhard (1980), "Moderne Verfahren der Großchemie: Braunstein", Chemie in Unserer Zeit, 14 (5): 137–48, doi:10.1002/ciuz.19800140502.

- Arthur Sutcliffe (1930) Practical Chemistry for Advanced Students (1949 Ed.), John Murray – London.

- Reidies, Arno H. (2002), "Manganese Compounds", Ullmann's Encyclopedia of Industrial Chemistry, 20, Weinheim: Wiley-VCH, pp. 495–542, doi:10.1002/14356007.a16_123, ISBN 978-3-527-30385-4

- Cahiez, G.; Alami, M.; Taylor, R. J. K.; Reid, M.; Foot, J. S. (2004), "Manganese Dioxide", in Paquette, Leo A. (ed.), Encyclopedia of Reagents for Organic Synthesis, New York: J. Wiley & Sons, pp. 1–16, doi:10.1002/047084289X.rm021.pub4, ISBN 9780470842898.

- Attenburrow, J.; Cameron, A. F. B.; Chapman, J. H.; Evans, R. M.; Hems, B. A.; Jansen, A. B. A.; Walker, T. (1952), "A synthesis of vitamin a from cyclohexanone", J. Chem. Soc.: 1094–1111, doi:10.1039/JR9520001094.

- Paquette, Leo A. and Heidelbaugh, Todd M. "(4S)-(−)-tert-Butyldimethylsiloxy-2-cyclopen-1-one". Organic Syntheses.CS1 maint: multiple names: authors list (link); Collective Volume, 9, p. 136 (this procedure illustrates the use of MnO2 for the oxidation of an allylic alcohol.

Cited sources

- Rumble, John R., ed. (2018). CRC Handbook of Chemistry and Physics (99th ed.). Boca Raton, FL: CRC Press. ISBN 978-1-1385-6163-2.

External links

| Wikimedia Commons has media related to Manganese dioxide. |