Byford Dolphin

Byford Dolphin is a semi-submersible, column-stabilised drilling rig operated by Dolphin Drilling, a Fred Olsen Energy subsidiary, and in 2009 contracted by BP for drilling in the United Kingdom section of the North Sea for three years.[3][4][5] It is registered in Hamilton, Bermuda.[1]

Byford Dolphin in dry dock at Invergordon (Scotland, UK) in 2008 | |

| History | |

|---|---|

| Name: |

|

| Owner: | Byford Dolphin Pte. Ltd. (Fred. Olsen Energy) |

| Operator: | Dolphin Drilling |

| Port of registry: | |

| Builder: | Aker Group |

| Yard number: | Aker Verdal A/S (695) |

| Laid down: | 31 October 1972 |

| Completed: | 1 February 1974 |

| Identification: |

|

| Status: | Operational |

| Notes: | [1][2] |

| General characteristics | |

| Class and type: | DNV class: 1A1 Column-stabilised Drilling Unit UKVS |

| Tonnage: | |

| Length: | 108.2 m (355 ft) |

| Beam: | 67.4 m (221 ft) |

| Depth: | 36.6 m (120 ft) |

| Speed: | 4.5 kn |

| Capacity: |

|

| Crew: | 102 berths |

| Notes: | [1][2] |

The rig has suffered some serious accidents, most notably an explosive decompression in 1983 that killed four divers and one dive tender, and badly injured another dive tender.[6]

Description

Byford Dolphin drilling rig is an Enhanced Aker H-3 design which was built by Aker Group at the Aker Verdal shipyard in 1974.[7] Between 1974 and 1978, it was named Deep Sea Driller.[1]

Byford Dolphin has a length of 108.2 metres (355 ft), breadth of 67.4 metres (221 ft) and depth of 36.6 metres (120 ft). It has a maximum drilling depth of 6,100 metres (20,000 ft), and it could operate at a water depth of 460 metres (1,500 ft).[8] As a drilling rig, Byford Dolphin is equipped with advanced drilling equipment and has to meet strict levels of certification under Norwegian law. Byford Dolphin is able to maneuver with its own engines (to counter drift and ocean currents), but for long-distance relocation, it must be moved by specialist tugboats.

| Operating deck load | 3,025 tonne |

| Crew quarters | 102 persons |

| Operating water depth | 460 metres (1,500 ft) maximum |

| Derrick | 49 m (160 ft) Shaffer top compensator |

| Mooring system | 12-point |

| Blow-out preventer | Hydril 476 mm (18.7 in), 10,000 kPa (1,500 psi) |

| Sub Sea Handling System | Christmas tree |

| Deck cranes | 2 × 40 tonnes |

Accidents and incidents

Deep Sea Driller accident

On 1 March 1976, the rig ran aground during transit from a block in the North Sea to Bergen. All crew were evacuated in the life boats, but six people died when they fell from their life boat.[9]

Diving bell accident

On Saturday, 5 November 1983 at 4:00 a.m., while drilling in the Frigg gas field in the Norwegian sector of the North Sea, four divers were in a diving chamber system on the rig's deck that was connected by a trunk (a short passage) to a diving bell. The divers were Edwin Arthur Coward (British, 35 years old), Roy P. Lucas (British, 38), Bjørn Giæver Bergersen (Norwegian, 29) and Truls Hellevik (Norwegian, 34). They were assisted by two dive tenders, William Brown Crammond and Martin Andrew Saunders.[6]

Hellevik was about to close the door between the chamber system and the trunk when the chamber explosively decompressed from a pressure of nine atmospheres to one atmosphere. One of the tenders, 32-year-old William Crammond of Great Britain, and all four of the divers were killed instantly; the other tender, Saunders, was severely injured.[10]

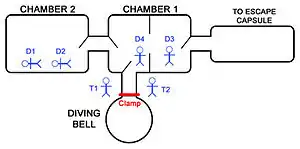

Just prior to the event, decompression chambers 1 and 2 (along with a third chamber which was not in use at the time) were connected via a trunk to a diving bell. The connection made by the trunk was kept sealed by a clamp operated by Crammond and Saunders, who were experienced divers. Coward and Lucas were resting in chamber 2 at a pressure of 9 atm. The diving bell with Bergersen and Hellevik had just been winched up after a dive and joined to the trunk. Leaving their wet equipment in the trunk, the two divers climbed through the trunk into chamber 1.[6]

The normal procedure would have been:

- Close the diving bell door, which would have been open to the trunk.

- Slightly increase the pressure in the diving bell to seal the bell door tightly.

- Close the chamber 1 door, which was also open to the trunk.

- Slowly depressurize the trunk until it reached a pressure of 1 atm.

- Open the clamp to separate the diving bell from the chamber system.

The first two steps had been completed when, for an unknown reason, Crammond opened the clamp that was keeping the trunk sealed before Diver 4 (Hellevik) could close the door to the chamber. This resulted in the explosive decompression of the unsealed chamber system. Air rushed out of the chamber system with tremendous force, jamming the interior trunk door and pushing the bell away, striking the two tenders. All four divers were killed; of the tenders Crammond was killed while Saunders was severely injured.[6]:94

Medical findings

Medical investigations were carried out on the remains of the four divers and of one of the tenders. The most notable finding was the presence of large amounts of fat in large arteries and veins and in the cardiac chambers, as well as intravascular fat in organs, especially the liver.[6]:97, 101 This fat was unlikely to be embolic, but must have precipitated from the blood in situ.[6]:101 The autopsy suggested that rapid bubble formation in the blood denatured the lipoprotein complexes, rendering the lipids insoluble.[6]:101 The blood of the three divers left intact inside the chambers likely boiled instantly, stopping their circulation.[6]:101 The fourth diver was dismembered and mutilated by the blast forcing him out through the partially blocked doorway and would have died instantly.[6]:95, 100–101

Coward, Lucas, and Bergersen were exposed to the effects of explosive decompression and died in the positions indicated by the diagram. Investigation by forensic pathologists determined that Hellevik, being exposed to the highest pressure gradient and in the process of moving to secure the inner door, was forced through the crescent-shaped opening measuring 60 centimetres (24 in) long created by the jammed interior trunk door. With the escaping air and pressure, it included bisection of his thoracoabdominal cavity, which resulted in fragmentation of his body, followed by expulsion of all of the internal organs of his chest and abdomen, except the trachea and a section of small intestine, and of the thoracic spine. These were projected some distance, one section being found 10 metres (30 ft) vertically above the exterior pressure door.[6]:95

Investigation

The committee investigating the accident concluded that it was caused by human error on the part of the dive tender who opened the clamp. The trunk door had a center hinge design, similar to a butterfly valve disc, the door was rotated too far to the left, causing the rim of the interior hatch to lodge on the door opening. This left a crescent shaped opening, similar to a manhole cover left ajar but held in place. This created an opening that was 24 inches across horizontally. It is not clear whether the tender who opened the clamp before the trunk was depressurized did so by order of his supervisor, on his own initiative, or because of miscommunication. At the time, the only communication the tenders on the outside of the chamber system had was through a bullhorn attached to the wall surface; with heavy noise from the rig and sea, it was hard to listen in on what was going on. Fatigue from many hard hours of work also took its toll among the divers, who often worked 16-hour shifts.

This incident was also attributed to engineering failure. The obsolete Byford Dolphin diving system, dating from 1975, was not equipped with fail-safe hatches, outboard pressure gauges, and an interlocking mechanism, which would have prevented the trunk from being opened while the system was under pressure.[11] Prior to the accident, Norske Veritas had issued the following rule for certification: "Connecting mechanisms between bell and chambers are to be so arranged that they cannot be operated when the trunk is pressurized,"[12] therefore requiring such systems to have fail-safe seals and interlocking mechanisms. One month after the accident, Norske Veritas and the Norwegian oil directorate made the rule final for all bell systems.

Among others, former crew members of Byford Dolphin and NOPEF (a Norwegian oil and petro-chemical union) have come forward and claimed the investigation was a cover-up. They claimed that the commission investigating the accident did not mention in their report the irresponsible dispensations on vital equipment requested by Comex and authorized by the diving section to the Norwegian Petroleum Directorate, which played a vital role in the accident's occurrence. They also alleged the accident was due to a lack of proper equipment, including clamping mechanisms equipped with interlocking mechanisms (which would be impossible to open while the chamber system was still under pressure), outboard pressure gauges, and a safe communication system, all of which had been held back because of dispensations by the Norwegian Petroleum Directorate.[13]

Lawsuit

The North Sea Divers Alliance, formed by early North Sea divers and the relatives of those killed, continued to press for further investigation and, in February 2008, obtained a report that indicated the real cause was faulty equipment. Clare Lucas, daughter of Roy Lucas, said: "I would go so far as to say that the Norwegian Government murdered my father because they knew that they were diving with an unsafe decompression chamber."[14] The families of the divers eventually received compensation for the damages from the Norwegian government 26 years after the incident.[15]

Other incidents

On 17 April 2002, a 44-year-old Norwegian worker on the rig was struck on the head and killed in an industrial accident. The accident resulted in Byford Dolphin losing an exploration contract with Statoil, which expressed concerns with the rig's operating procedures. The incident cost the company millions of dollars in lost income.[15]

See also

- Commercial offshore diving – Professional diving in support of the oil and gas industry

- Saturation diving – Diving for periods long enough to bring all tissues into equilibrium with the partial pressures of the inert components of the breathing gas

- Piper Alpha – Oil platform destroyed by explosion and fire in 1988 oil production platform

- Pioneer – 2013 film, a fictional film set in the 1970s Norwegian oil industry, and which features a fatal decompression chamber accident and its cover-up

References

- "Byford Dolphin (09092)". DNV GL Vessel Register. Det Norske Veritas. Retrieved 14 July 2010.

- "Byford Dolphin". Fred.Olsen Energy ASA. 24 February 2008. Retrieved 14 July 2010.

- "Byford Dolphin gets Senergy extra-time". Upstream. NHST Media Group. 19 May 2009. Retrieved 23 May 2010.

- "Fred Olsen upgrading fleet for drilling upturn". Offshore Magazine. PennWell Corporation. 17 February 2010. Archived from the original on 30 September 2011. Retrieved 23 May 2010.

- Kolstad, Elisabeth (18 December 2009). "Byford Dolphin-agreement". Offshore.no International. Offshore Media Group. Archived from the original on 23 February 2013. Retrieved 5 November 2012.

- Giertsen JC, Sandstad E, Morild I, Bang G, Bjersand AJ, Eidsvik S (June 1988). "An explosive decompression accident". American Journal of Forensic Medicine and Pathology. 9 (2): 94–101. doi:10.1097/00000433-198806000-00002. PMID 3381801.

- "Rig Data: Byford Dolphin". Rigzone. Archived from the original on 7 June 2011. Retrieved 23 May 2010.

- "Byford Dolphin" (PDF). Fred. Olsen Energy. Archived from the original (PDF) on 20 July 2011. Retrieved 23 May 2010.

- Deep Sea Driller-ulykken Store norske leksikon. Retrieved 29 September 2014

- Limbrick, Jim (2001). North Sea Divers - a Requiem. Hertford: Authors OnLine. pp. 168–170. ISBN 0-7552-0036-5.

- Dykkerulykken på Byford Dolphin 5 november 1983 : rapport fra ekspertkommisjonen [The Diving Accident at Buford Dolphin on 5 November 1983: Report of the Expert Commission]. Norges Offentlige Utredninger [Norwegian Public Reports] (Report) (in Norwegian Bokmål). Oslo: Universitetsforlaget. 1984. ISBN 9788200708896. OCLC 470294994. NOU 1984:11 – via Nasjonalbiblioteket, Norway.

- "Sec 3 B305". Rules for certification of diving systems, 1982. Det Norske Veritas. 1982. OCLC 9287902.

- Ringheim, Gunnar (22 March 2008). "Historiens verste dykkerulykke" [History's worst diving accident] (in Norwegian). Oslo: Dagbladet.no. Archived from the original on 5 June 2011. Retrieved 18 November 2009.

- Lister, David (25 March 2008). "Families of British divers killed in North Sea oil boom sue Norway". The Times. London. Retrieved 18 November 2009.

- Staff writers (20 October 2009). "Norwegian government finally pays out for 1983 Byford Dolphin diver death". cDiver. Retrieved 14 July 2010.

Further reading

| Wikimedia Commons has media related to Byford Dolphin (ship, 1974). |

- Gjerde, Kristin Øye; Ryggvik, Helge (2009). Nordsjødykkerne [North Sea divers] (in Norwegian). Stavanger: Wigestrand Forlag. Archived from the original on 26 January 2018. Retrieved 14 July 2010. – A documentation of offshore diving and pioneer divers on the Norwegian continental shelf; contains a section on safety and responsibility

- Haddow, Iain (27 March 2008). "Norway's underwater 'guinea pigs'". BBC News Magazine. British Broadcasting Corporation. Retrieved 14 July 2010. – News report on Byford Dolphin and other incidents in the North Sea